Pulse type lift pipe regenerator

A riser and regenerator technology, applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low carbon content of catalysts, low charring strength, and reduced regenerator size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

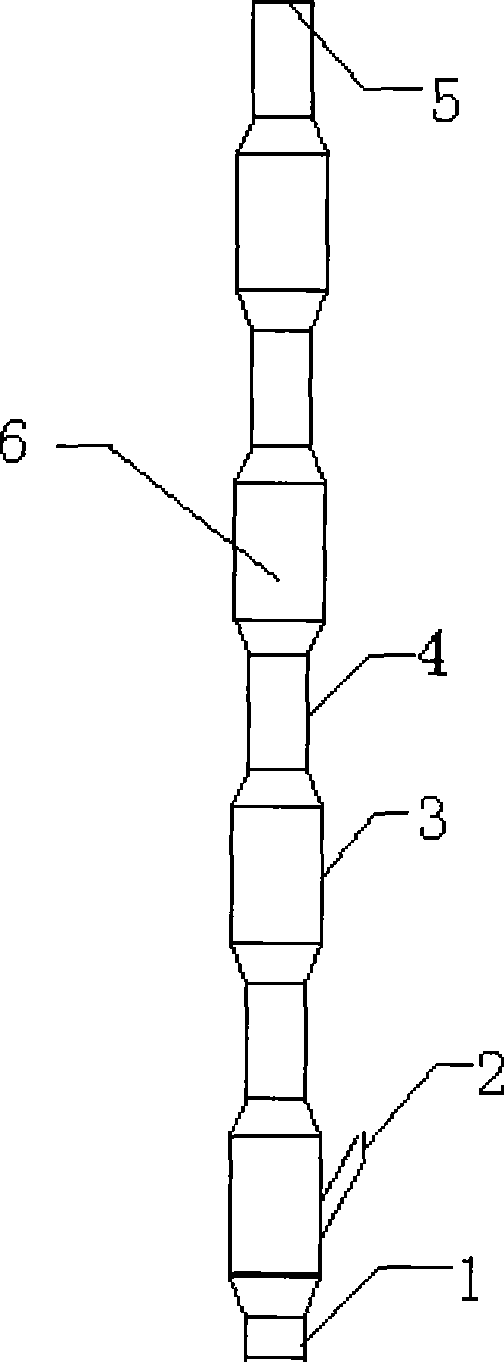

[0011] Below in conjunction with accompanying drawing, the present invention is described in detail: in actual design and manufacture, the present invention is to form the combination of large pipe (3) and small pipe (4) by alternately reducing and expanding the pipe diameter of riser regenerator (6) In the impulse riser, the pipe diameter ratio of the large pipe (3) to the small pipe (4) is 1.3-3. During operation, the spent agent added from the regenerant inlet (2) and the air entering from the riser inlet (1) form a rapid turbulent bed scorching in the first large pipe (3) at the lower part of the riser, which solves the problem of Difficulty in burning the riser tube; when the accelerated spent agent enters the small tube, the particles are accelerated. When the accelerated motion ends, the diameter of the riser tube suddenly expands, and the particles enter the large tube by inertia; the particles are in the process of movement. Due to the resistance, it decelerates conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com