Preparation method of SiC foam, SiC foam monolithic catalyst for catalytic combustion of methane, and preparation method thereof

A monolithic catalyst and foam technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, catalyst carrier, etc., can solve the problems that the catalyst is difficult to achieve the catalytic effect, the thermal matching of SiC foam is poor, and the second carrier is unevenly loaded. , to achieve the effects of industrial utilization, good thermal expansion coefficient matching, and stable phase structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

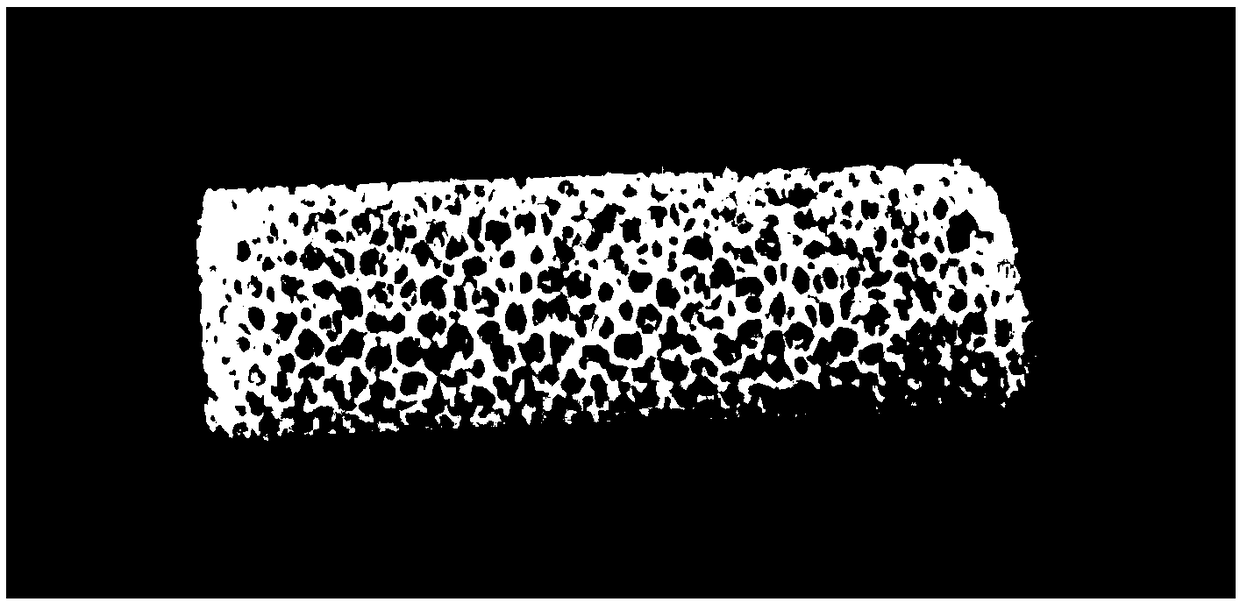

[0041] A kind of preparation method of SiC foam, take the glassy carbon foam (RVC carbon foam) with porosity 97% with three-dimensional network structure as template, take polysilane (PMS) as silicon source, take xylene as solvent, comprising The following steps:

[0042] (1) According to the mass ratio of 1:1, PMS and xylene were mixed and stirred continuously for 1 h to obtain a PMS solution.

[0043] (2) Place the carbon foam in the PMS solution obtained in step (1), soak it for 12 hours, take out the carbon foam, drain it, and dry it in a 60°C oven for 24 hours to obtain a carbon foam impregnated with PMS; the carbon foam used is RVC carbon foam with a three-dimensional network structure, with a porosity of 97%.

[0044] (3) Under the protection of Ar, the carbon foam impregnated with PMS obtained in step (2) was reacted at a high temperature of 1600°C for 3h to obtain a SiC foam with a three-dimensional network structure.

[0045] The porosity of the SiC foam prepared i...

Embodiment 2

[0047] A kind of preparation method of SiC foam, take the glassy carbon foam (RVC carbon foam) with porosity 90% with three-dimensional network structure as template, take polysilane (PMS) as silicon source, take xylene as solvent, comprising The following steps:

[0048] (1) According to the mass ratio of 1:1, PMS and xylene were mixed and stirred continuously for 1 h to prepare a PMS solution.

[0049] (2) Place the carbon foam in the PMS solution obtained in step (1), soak it for 12 hours, take out the carbon foam, drain it, and dry it in a 60°C oven for 24 hours to obtain a carbon foam impregnated with PMS; the carbon foam used is RVC carbon foam with a three-dimensional network structure and a porosity of 90%.

[0050] (3) Under the protection of Ar, the carbon foam impregnated with PMS obtained in step (2) was reacted at a high temperature of 1600°C for 3h to obtain a SiC foam with a three-dimensional network structure.

[0051] The SiC foam prepared in Example 2 of th...

Embodiment 3

[0054] A SiC foam monolithic catalyst for catalytic combustion of methane, comprising a first carrier, wherein the first carrier is SiC foam; a transition layer is deposited on the SiC foam, a second carrier is deposited on the transition layer, and the SiC foam monolithic catalyst Loaded with precious metals.

[0055] In this embodiment, the molar ratio of carbon and silicon in the SiC foam is 1.1:1; the SiC foam has a three-dimensional network structure, a porosity of 97%, and a compressive strength of 1.3 MPa.

[0056] In this embodiment, the transition layer is mullite; the thickness of the transition layer is 5 μm; the mass of the transition layer is 29% of the total mass of the SiC foam monolithic catalyst.

[0057] In this embodiment, the second carrier is a pyrochlore phase oxide, specifically La 2 Zr 2 o 7 The thickness of the second carrier is 41 μm; the quality of the second carrier is 57% of the total mass of the SiC foam monolithic catalyst; the average particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com