Method for preparing berry crisp chips

A berry and chip technology, applied in the field of preparing berry chips, can solve the problems of consuming a lot of time and energy, uneven heating of fruits and vegetables, long drying cycle, etc., and achieve the goal of improving color, shortening vacuum freeze-drying time, and improving berry color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

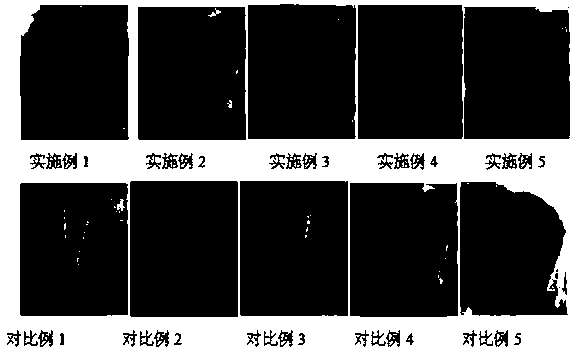

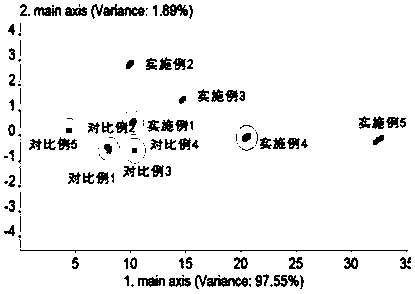

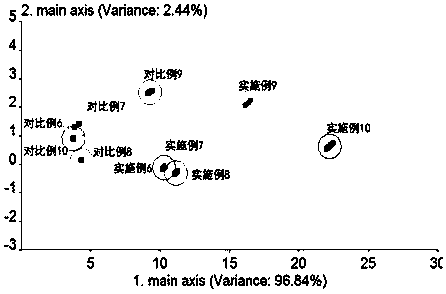

Image

Examples

Embodiment 1

[0021] For raw material selection, select strawberries with a complete surface, no bad spots, and no rot.

[0022] Cleaning treatment, cleaning the selected strawberries to remove dust and stains on the surface.

[0023] Slicing, the cleaned strawberries are sliced into 5-6mm thin slices.

[0024] For freezing treatment, the thinly sliced strawberries were frozen at -19°C for 24 hours to freeze them.

[0025] Ultra-high pressure pretreatment, vacuum-pack frozen strawberry slices and put them into ultra-high pressure equipment, and then use water as the medium to perform ultra-high pressure treatment. The ultra-high pressure is 100MPa, the holding time is 5min, and the temperature is 20°C.

[0026] Ultrasonic pretreatment, put the strawberries pretreated by ultra-high pressure into the ultrasonic instrument, the ultrasonic power is 100w, the ultrasonic time is 20min, the ultrasonic frequency is 20KHZ, and the temperature of the system is controlled at 20-25°C during ultras...

Embodiment 2

[0029] For raw material selection, select strawberries with a complete surface, no bad spots, and no rot.

[0030] Cleaning treatment, cleaning the selected strawberries to remove dust and stains on the surface.

[0031] Slicing, the cleaned strawberries are sliced into 5-6mm thin slices.

[0032] For freezing treatment, the thinly sliced strawberries were frozen at -40°C for 18 hours to freeze them.

[0033] Ultra-high pressure pretreatment, vacuum-pack frozen strawberry slices and put them into ultra-high pressure equipment, and then use water as the medium to perform ultra-high pressure treatment. The ultra-high pressure is 100 MPa, the holding time is 5 minutes, and the temperature is 23 °C.

[0034] Ultrasonic pretreatment, put the strawberries pretreated by ultra-high pressure into an ultrasonic instrument, the ultrasonic power is 100w, the ultrasonic time is 20min, the ultrasonic frequency is 30KHZ, and the system temperature is controlled at 20-25°C during ultraso...

Embodiment 3

[0037] For raw material selection, select strawberries with a complete surface, no bad spots, and no rot.

[0038] Cleaning treatment, cleaning the selected strawberries to remove dust and stains on the surface.

[0039] Slicing, the cleaned strawberries are sliced into 5-6mm thin slices.

[0040] For freezing treatment, the thinly sliced strawberries were frozen at -80°C for 12 hours to freeze them.

[0041] Ultra-high pressure pretreatment, the frozen strawberry slices are vacuum-packed and placed in ultra-high pressure equipment, and then water is used as the medium for ultra-high pressure treatment. The ultra-high pressure is 100MPa, the holding time is 5min, and the temperature is 25°C.

[0042] Ultrasonic pretreatment, put the strawberries pretreated by ultra-high pressure into an ultrasonic instrument, the ultrasonic power is 100w, the ultrasonic time is 20min, the ultrasonic frequency is 40KHZ, and the system temperature is controlled at 20-25°C during ultrasonica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com