Device for continuously separating methane in coalbed methane-air mixture by using hydrate

A technology of hydrate and coalbed methane, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of high cost and low efficiency, and achieve the effect of low investment cost and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

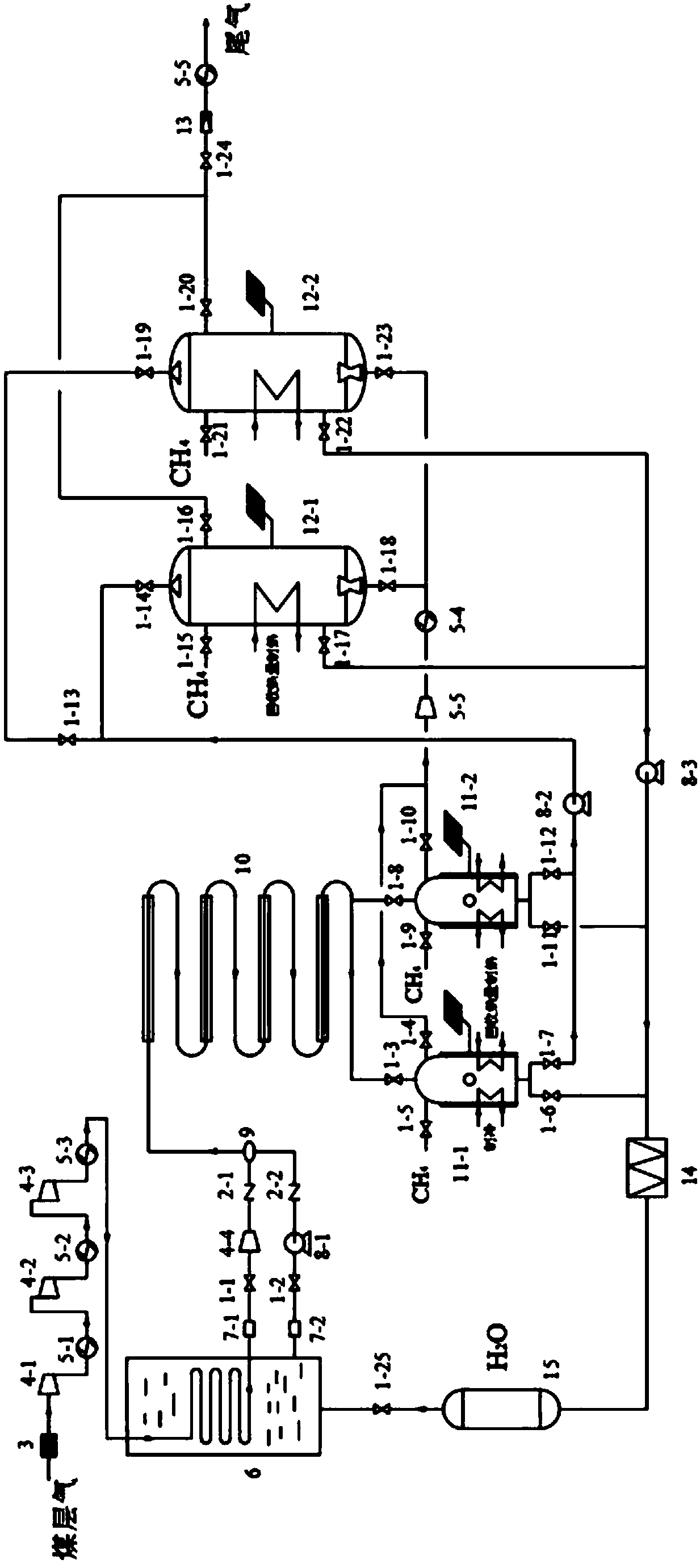

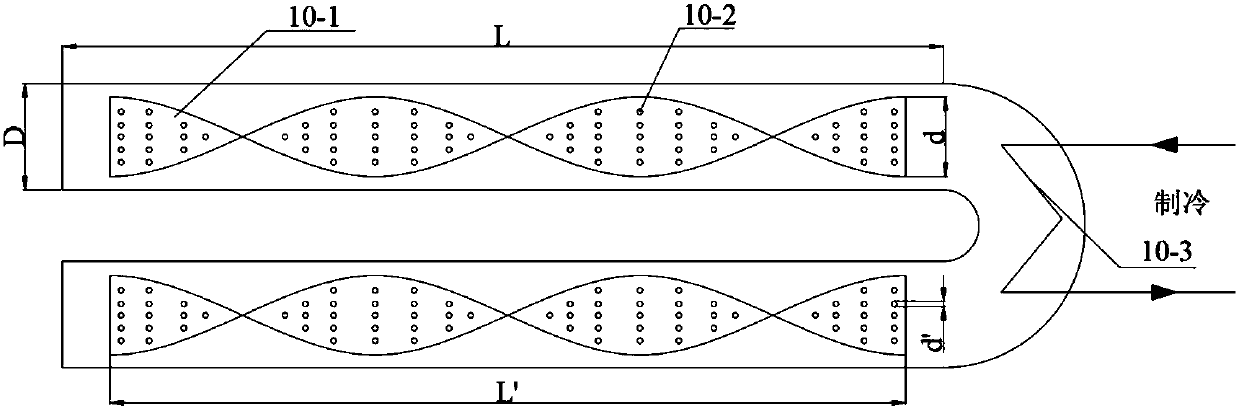

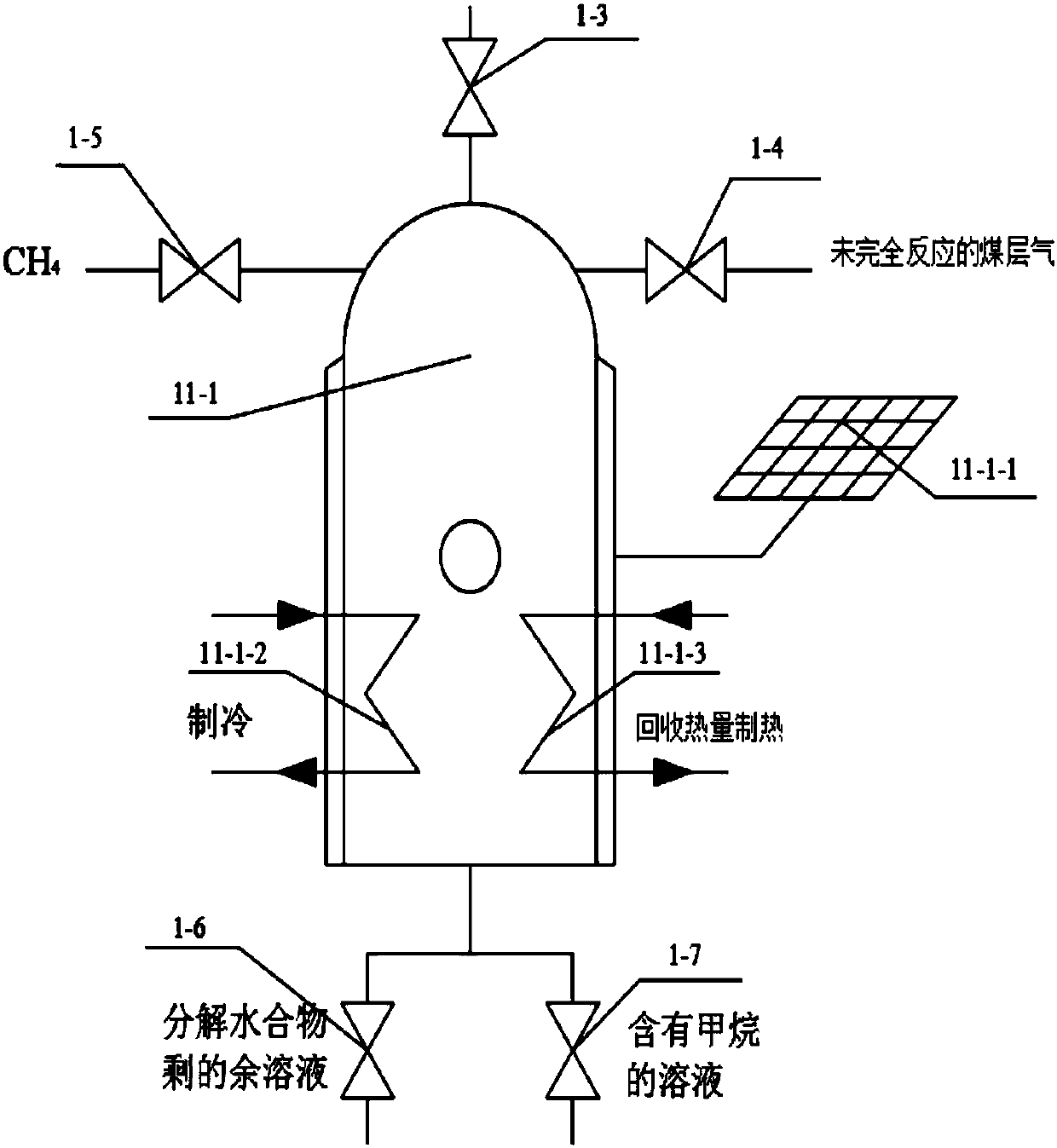

[0033] Below in conjunction with accompanying drawing and specific embodiment, content of the present invention is described in further detail, and promptly is the specific parameter of a set of device below:

[0034] The main component of coalbed methane (0.1MPa, 25°C) is CH 4 65%, SO 2 3%, CO 2 12%, N 2 20%, the main component is CH 4 76.5%, N 2 23.5% (CH 4 The hydrate formation temperature is 260-285K, and the formation pressure is 2-8Mpa; N 2 The formation temperature of the hydrate is 270-275k, and the formation pressure is 14-20Mpa), and the cold generated during the process of passing the exhausted tail gas through the pressure reducing valve 14 is recovered by the heat exchanger 5-5 to carry out preliminary pre-cooling of the gas to make it The temperature reaches about 10°C. Then, the coalbed methane is pressurized to 8MPa by three compressors in series, that is, the first compressor 4-1, the second compressor 4-2, and the third compressor 4-3. Behind each com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com