Method and drying device for drying fruits and vegetables through contact-type ultrasonic-assisted hot air drying mode and

A technology of hot air drying and ultrasonic wave, applied in the direction of drying gas arrangement, drying solid materials without heating, and promoting the preliminary treatment of solid material drying, can solve the problems of energy waste, shorten drying time, reduce energy consumption, etc., and achieve improved transmission efficiency. Heat mass transfer rate, save drying time, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

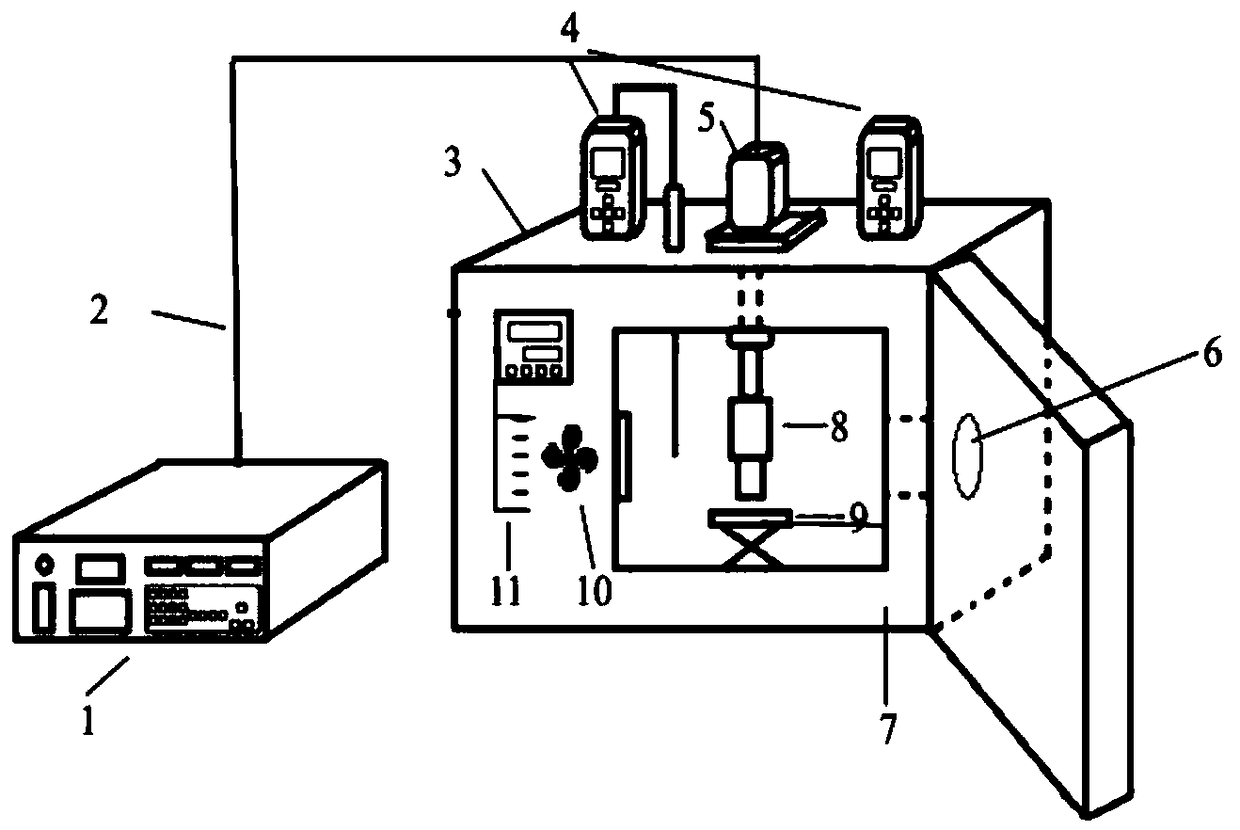

Method used

Image

Examples

Embodiment 1

[0026] (1) Select fresh garlic with a complete shape and no pests and diseases, peel off the outer skin, wash and cut into thin slices with a thickness of 3 mm.

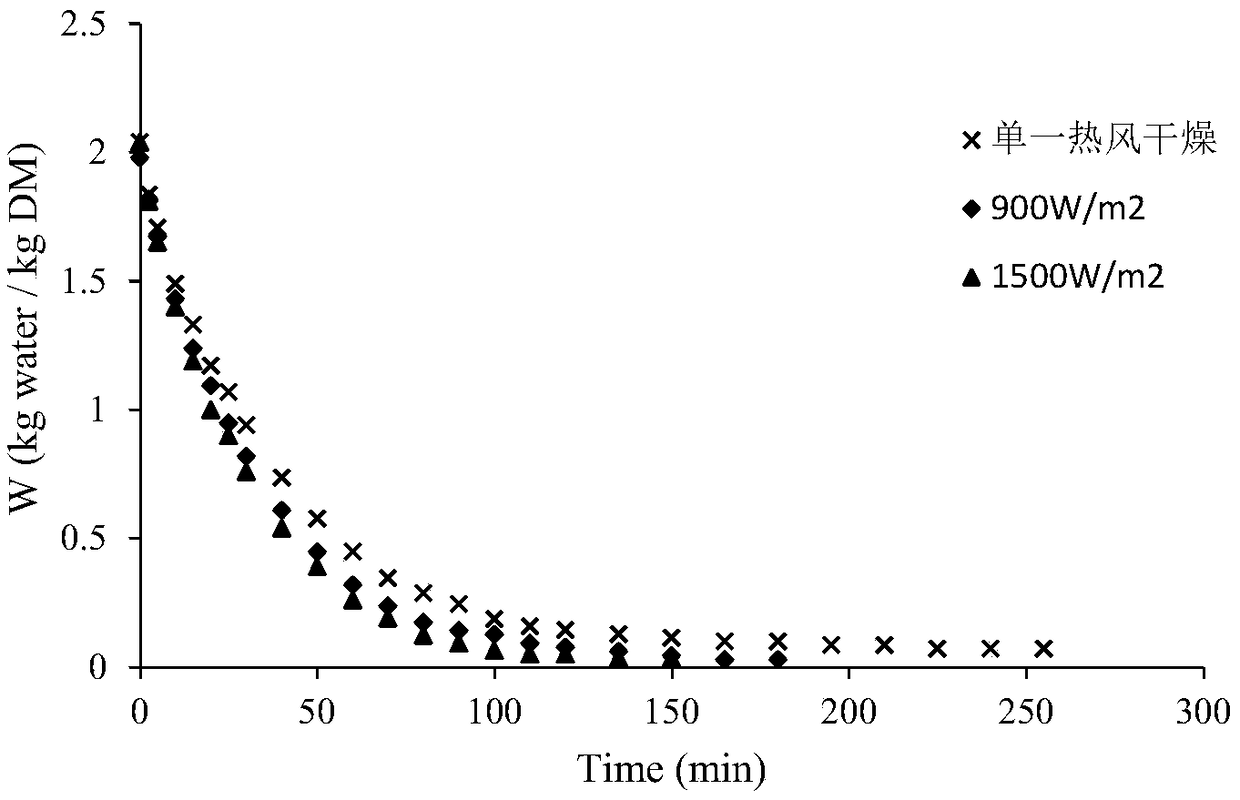

[0027] (2) Place the garlic slices on the drying tray, and adjust the height so that the garlic slices are in contact with the ultrasonic probe, adjust the drying temperature of the hot air drying oven to 60°C, the wind speed to 2.5m / s, and the ultrasonic power to 900W / m 2 , the ultrasonic frequency is 20kHz, and the drying end point can be reached after drying for 105 minutes.

Embodiment 2

[0029] (1) Select fresh garlic with a complete shape and no pests and diseases, peel off the outer skin, wash and cut into 2.7mm thick slices.

[0030] (2) Place the sliced garlic on the drying tray, and adjust the height so that the sliced garlic is in contact with the ultrasonic probe, adjust the drying temperature of the hot air drying oven to 60°C, the wind speed to 2.5m / s, and the ultrasonic power to 1500W / m 2 , the ultrasonic frequency is 20kHz, and the drying end point can be reached after drying for 85 minutes.

Embodiment 3

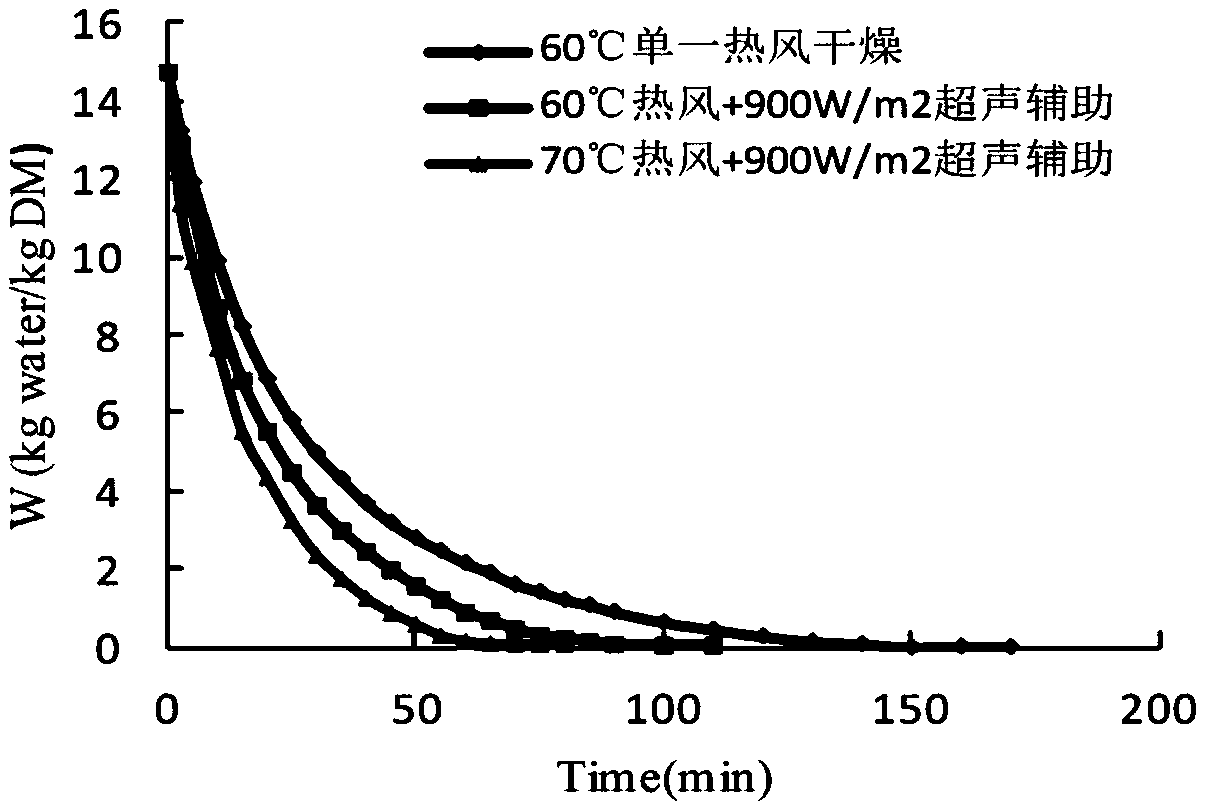

[0032] (1) Take fresh and clean cabbage and peel off 2 outer leaves, take the 3rd-10th leaf, and cut the parts with similar tissue thickness into small pieces of 1cm×1cm.

[0033] (2) Place the small pieces of cabbage on the drying tray and adjust the height so that the small pieces of cabbage are in contact with the ultrasonic probe. Adjust the drying temperature of the hot air drying oven to 60°C, the wind speed to 3.0m / s, and the ultrasonic power to 900W / m 2 , the ultrasonic frequency is 20kHz, and the drying end point can be reached after drying for 110 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com