Expansible fire retardant containing fluorine-phosphorus-nitrogen oligomer and preparation method thereof

An intumescent flame retardant and oligomer technology, applied in the field of flame retardants, can solve the problems of large addition, poor stability, and high moisture absorption, and achieve improved water resistance, good thermal stability, and char formation rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

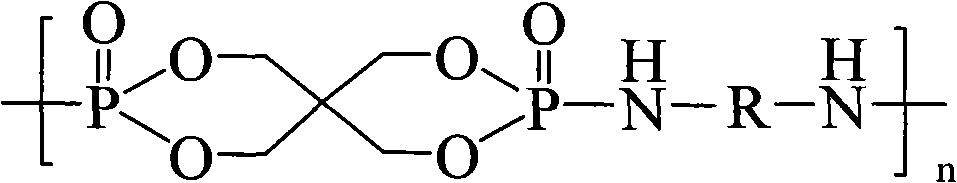

Method used

Image

Examples

Embodiment 1

[0026] a. In a nitrogen atmosphere, first dissolve pentaerythritol diphosphate diphosphoryl chloride in acetonitrile solvent, and massage pentaerythritol diphosphate diphosphoryl chloride and 2-trifluoromethyl-4-4-diaminodiphenyl ether according to the The molar ratio is 1: 1 mixing, and it is 65 ℃ of reactions at temperature for 9 hours, and wherein the consumption of acetonitrile is 2 times of the total mass of pentaerythritol diphosphate diphosphoryl chloride and diamine; Wherein pentaerythritol diphosphate diphosphoryl chloride is made of Obtained by reacting pentaerythritol and phosphorus oxychloride at a molar ratio of 1:7 at 80°C for 24 hours;

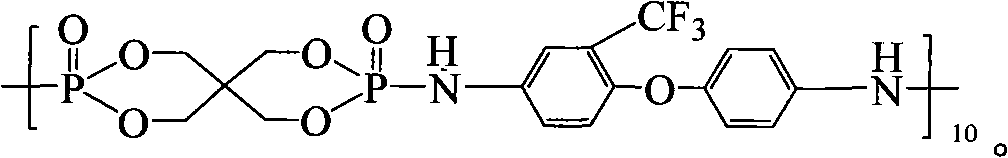

[0027] b. Filter the above reaction product, wash the obtained filter residue twice with deionized water, then wash twice with absolute ethanol, and dry in a vacuum oven at 80°C for 24 hours to obtain the fluorine-phosphorus-nitrogen oligomer Intumescent flame retardant, its structural formula is:

[0028]

[0029] Flame ret...

Embodiment 2

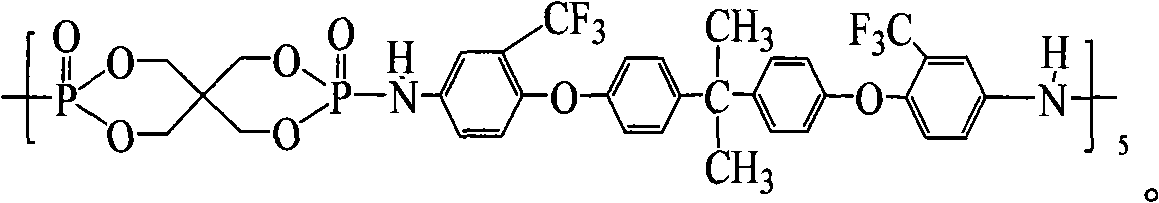

[0034] a. In a nitrogen atmosphere, first dissolve pentaerythritol diphosphate diphosphoryl chloride in acetonitrile solvent, and mix pentaerythritol diphosphate diphosphoryl chloride with 2,2-bis[4-(4-amino-2-trifluoromethane Base phenoxy) phenyl] propane mixed according to the molar ratio of 1: 1.5, at a temperature of 70 ° C for 8 hours, wherein the amount of acetonitrile is 3 times the total mass of pentaerythritol diphosphate diphosphoryl chloride and diamine ; Wherein pentaerythritol diphosphate diphosphoryl chloride is obtained by reacting pentaerythritol and phosphorus oxychloride according to a molar ratio of 1:3 at 105° C. for 16 hours;

[0035] b. Filter the above reaction product, wash the obtained filter residue twice with deionized water, then wash twice with absolute ethanol, and dry in a vacuum oven at 80°C for 24 hours to obtain the fluorine-phosphorus-nitrogen oligomer Intumescent flame retardant, its structural formula is:

[0036]

[0037] Flame retarda...

Embodiment 3

[0042]a. In a nitrogen atmosphere, first dissolve pentaerythritol diphosphate diphosphoryl chloride in acetonitrile solvent, and mix pentaerythritol diphosphate diphosphoryl chloride with 1,4-bis(4-amino-2-trifluoromethylphenoxy Base) benzene was mixed according to the molar ratio of 1:1.5, and reacted at a temperature of 75°C for 7 hours, wherein the amount of acetonitrile was 4 times the total mass of pentaerythritol diphosphate diphosphoryl chloride and diamine; wherein pentaerythritol diphosphate Diphosphoryl chloride is obtained by reacting pentaerythritol and phosphorus oxychloride at a molar ratio of 1:5 at 100°C for 20 hours;

[0043] b. Filter the above reaction product, wash the obtained filter residue twice with deionized water, then wash twice with absolute ethanol, and dry in a vacuum oven at 80°C for 24 hours to obtain the fluorine-phosphorus-nitrogen oligomer Intumescent flame retardant, its structural formula is:

[0044]

[0045] Flame retardant applicatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com