Lithium ion battery electrolyte and lithium ion battery

A lithium-ion battery, electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., to achieve the effect of reducing content, protecting performance, improving electrochemical performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

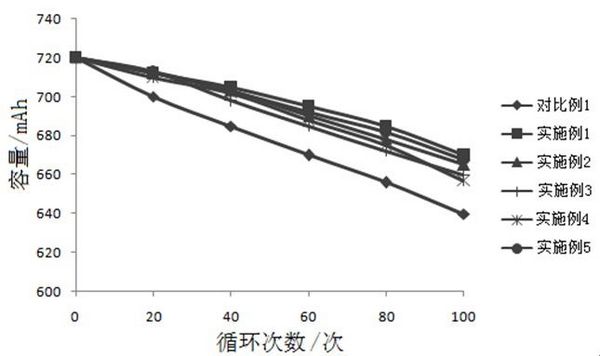

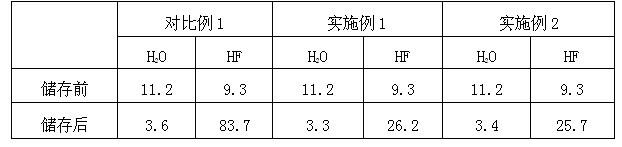

Examples

Embodiment 1

[0022] Electrolyte preparation: Take 80 parts by weight of ethylene carbonate and diethyl carbonate (mass ratio: 1:2) and mix evenly, slowly add 10 parts by weight of 1.0mol / L LiPF6, stir to make Fully dissolve, then add 0.45 parts by weight of hexamethyldisilazane, and fully stir.

[0023] Preparation of battery positive electrode: Dissolve polyvinylidene fluoride in a certain amount of N-methylpyrrolidone solvent to prepare a binder solution, add LiCoO2 and acetylene black powder to achieve uniform mixing, and stir at high speed for 1 to 3 hours to obtain the positive electrode Slurry, the slurry is evenly coated on the aluminum foil current collector with a thickness of 20??m by a pulper, vacuum-dried at 150°C for 1.5 hours, rolled, cut into pieces, and welded on the positive electrode tab. Among them: the mass ratio of LiCoO2, acetylene black and polyvinylidene fluoride is 90:5:5.

[0024] Production of battery negative electrode: Mix artificial graphite, carbon fiber and...

Embodiment 2

[0027] Electrolyte preparation: Take 80 parts by weight of ethylene carbonate and diethyl carbonate (mass ratio: 1:2) and mix evenly, slowly add 10 parts by weight of 1.0mol / L LiPF6, stir to make Fully dissolve, then add 2 parts by weight of hexamethyldisilazane and vinylene carbonate (mass ratio is 1:3, that is, 0.5 parts of hexamethyldisilazane, 1.5 parts of vinylene carbonate), Stir well.

[0028] Preparation of battery positive electrode: Dissolve polyvinylidene fluoride in a certain amount of N-methylpyrrolidone solvent to prepare a binder solution, add LiCoO2 and acetylene black powder to achieve uniform mixing, and stir at high speed for 1 to 3 hours to obtain the positive electrode Slurry, the slurry is evenly coated on the aluminum foil current collector with a thickness of 20??m by a pulper, vacuum-dried at 150°C for 1.5 hours, rolled, cut into pieces, and welded on the positive electrode tab. Among them: the mass ratio of LiCoO2, acetylene black and polyvinylidene ...

Embodiment 3

[0035] Electrolyte preparation: take 55 parts by weight of ethylene carbonate and diethyl carbonate (mass ratio 1:3) and mix evenly, slowly add 10 parts by weight of 1.0mol / L LiPF6, stir to make Fully dissolve, then add 0.4 parts by weight of hexamethyldisilazane and vinylene carbonate (mass ratio is 1:3, that is, 0.1 part of hexamethyldisilazane, 0.3 parts of vinylene carbonate), Stir well.

[0036] Preparation of battery positive electrode: Dissolve polyvinylidene fluoride in a certain amount of N-methylpyrrolidone solvent to prepare a binder solution, add LiCoO2 and acetylene black powder to achieve uniform mixing, and stir at high speed for 1 to 3 hours to obtain the positive electrode Slurry, the slurry is evenly coated on the aluminum foil current collector with a thickness of 20??m by a pulper, vacuum-dried at 150°C for 1.5 hours, rolled, cut into pieces, and welded on the positive electrode tab. Among them: the mass ratio of LiCoO2, acetylene black and polyvinylidene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com