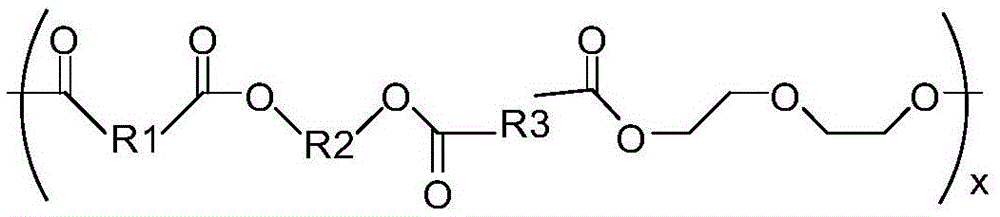

Diethylene glycol copolymerized halogen-free flame-retardant unsaturated polyester resin and preparation method thereof

A polyester resin, unsaturated technology, applied in the field of diethylene glycol copolymerization of halogen-free flame retardant unsaturated polyester resin and its preparation, can solve the problem of inability to be linked with flame retardant, achieve excellent flame retardant effect, bending Strength and tensile strength increase, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

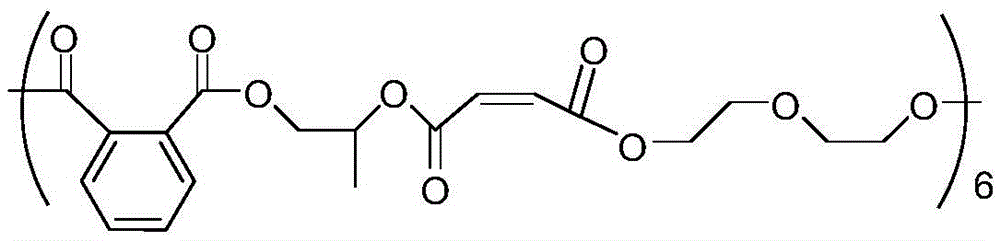

Embodiment 1

[0021] Add 29.62g of phthalic anhydride, 19.62g of maleic anhydride, 16.73g of 1,2-propanediol, 23.35g of diethylene glycol, 0.87 g dibutyltin oxide. Heat up to 140°C and start mechanical stirring. After the monomers are all dissolved, raise the temperature to 160°C, and control the temperature for one hour, then continue to raise the temperature to 170°C, 180°C, and 190°C respectively, and control the temperature for one hour. Raise the temperature to 190-200°C, continue the reaction for 5 hours, and then measure the acid value every half hour. When the acid value of the system reaches 36mgKOH / g, stop the reaction, cool down to 160°C, depressurize and vacuumize during the cooling process, add 0.0087g polymerization inhibitor, stirred for 10min. Continue to lower the temperature to 90°C, add 30.42g of styrene weighed in advance to dilute, control the temperature and stir for 30 minutes to stabilize the system, and finally discharge to obtain an unsaturated polyester resin pr...

Embodiment 2

[0025] Add 29.62g of phthalic anhydride, 19.62g of maleic anhydride, 10.04g of 1,2-propanediol, 32.68g of diethylene glycol, 0.87 g dibutyltin oxide. The polycondensation program temperature control and diluent addition method and the structural formula of the unsaturated polyester resin prepolymer are the same as in Example 1. The number average molecular weight Mn of the prepolymer is 2600g / mol, and the weight average molecular weight is 3900g / mol. 100 parts of the unsaturated polyester resin prepolymer, 1.5 parts of methyl ethyl ketone peroxide, 0.2 parts of cobalt composite accelerator, stirred evenly, removed air bubbles, and demolded after curing at room temperature for 2 hours. After testing, its oxygen index is 26%, the tensile strength is 55.1MPa, the bending strength is 82.8MPa, and the impact strength is 11.5KJ / m 2 .

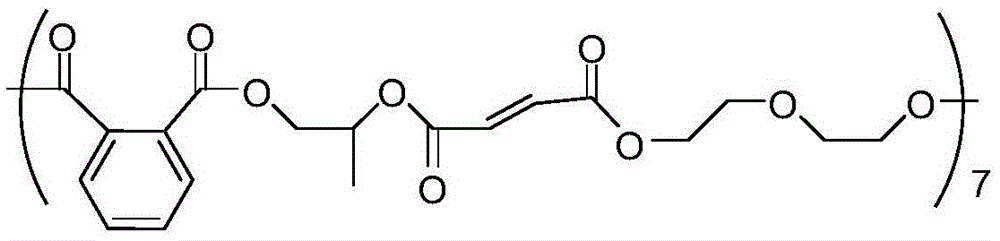

Embodiment 3

[0027] Add 29.62g of phthalic anhydride, 19.62g of maleic anhydride, 23.41g of 1,2-propanediol, 14.01g of diethylene glycol, 0.87 g dibutyltin oxide. The polycondensation program temperature control and diluent addition method and the structural formula of the unsaturated polyester resin prepolymer are the same as in Example 1. The number average molecular weight Mn of the prepolymer is 2400g / mol, and the weight average molecular weight is 3500g / mol. 100 parts of the unsaturated polyester resin prepolymer, 1.5 parts of methyl ethyl ketone peroxide, 0.2 parts of cobalt composite accelerator, stirred evenly, removed air bubbles, and demolded after curing at room temperature for 2 hours. After testing, its oxygen index is 25%, the tensile strength is 39.1MPa, the bending strength is 82.8MPa, and the impact strength is 11.5KJ / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com