A type of oil storage atomizer with vibration

An atomizer and vibrating cavity technology, applied in the field of vibrating oil storage atomizer, can solve the problems of large volume of electronic cigarette and large ultrasonic generating device, and achieve good user experience, good coaxial performance, and low use cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further clarified through the detailed description of specific embodiments below, but the present invention is not limited thereto.

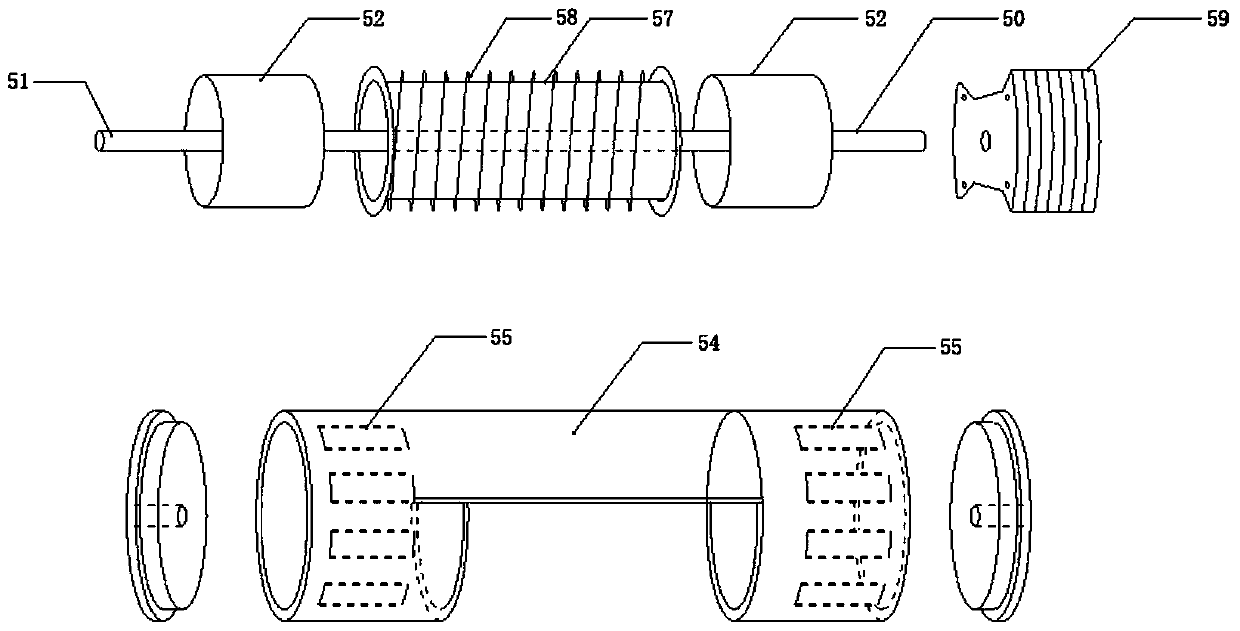

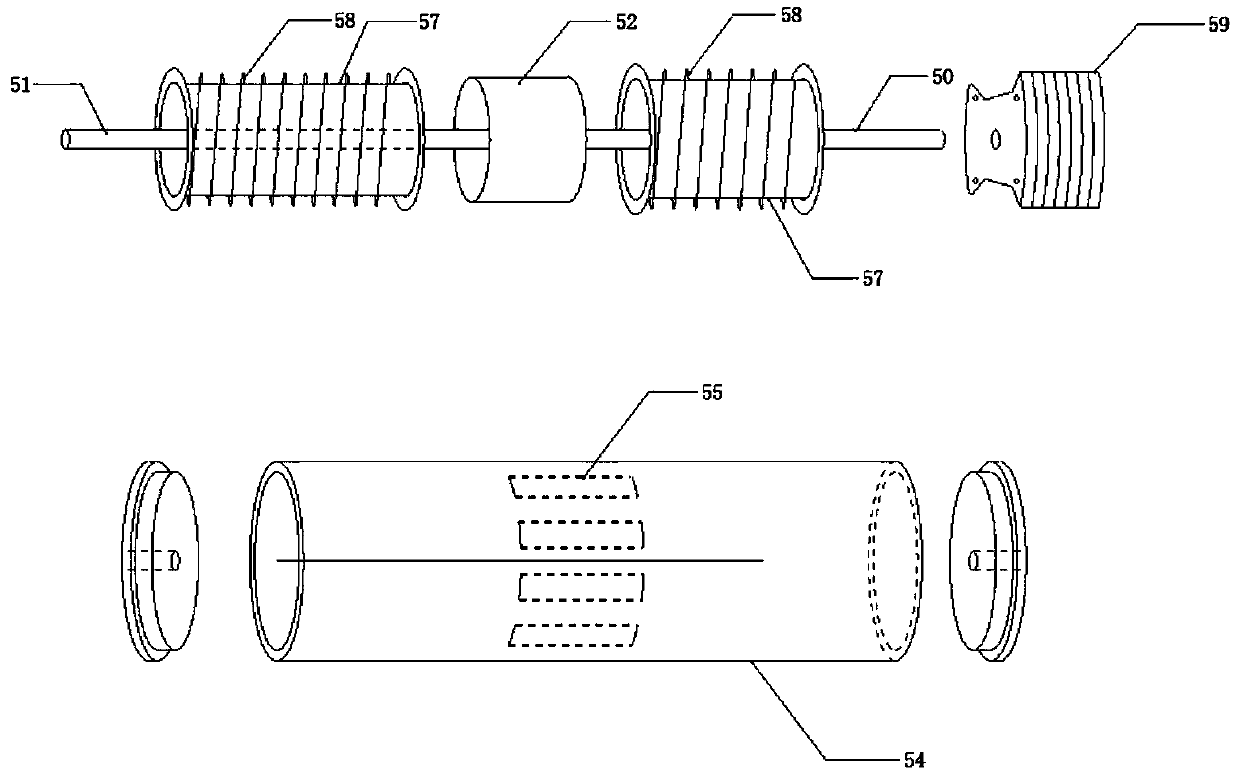

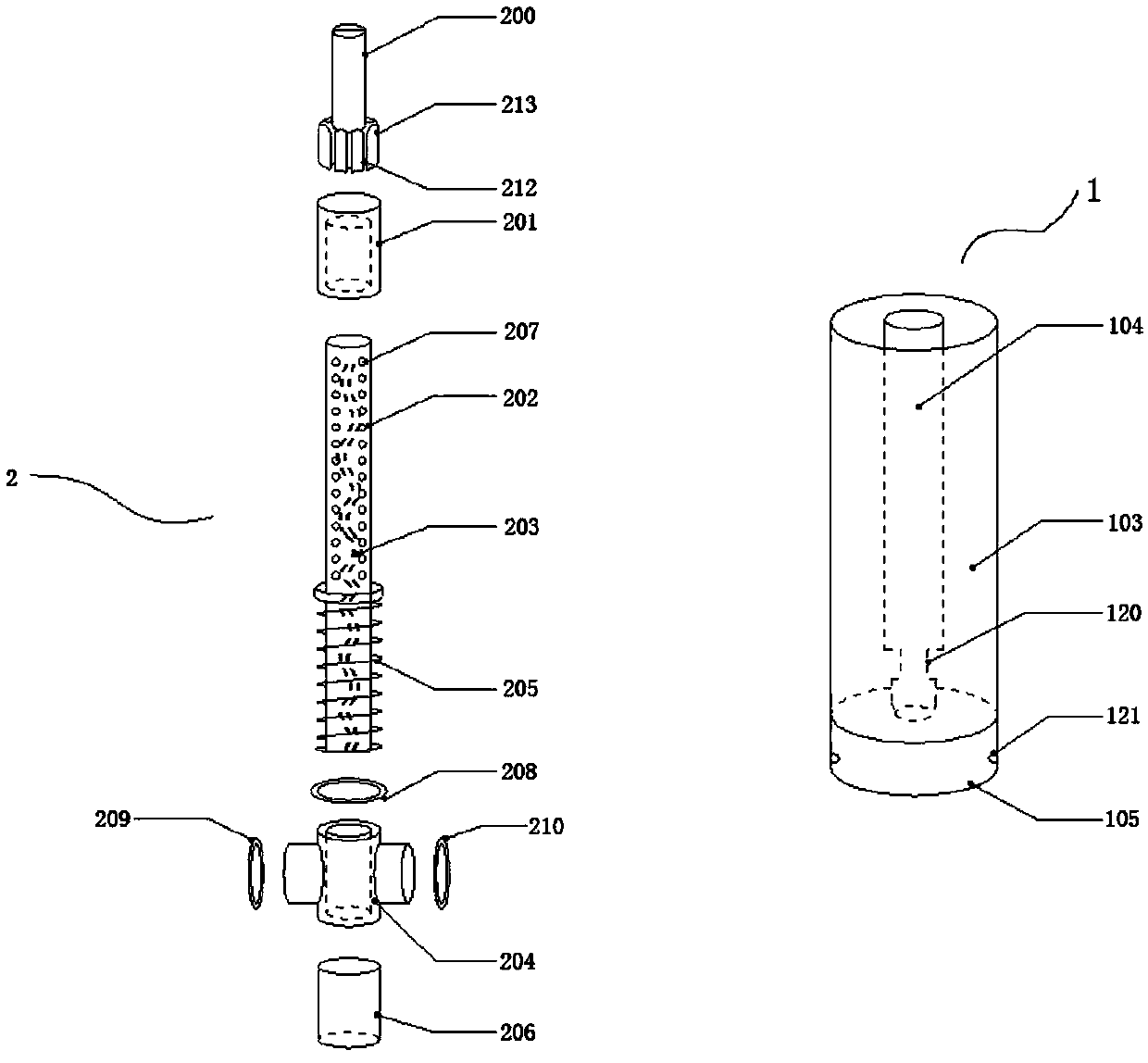

[0073] The working principle and process of the magnetic levitation vibrator in the present invention are as follows: after the coil (which can be a single coil or double coil) of the magnetic levitation vibrator is loaded with the electric energy provided by the rechargeable battery, it is generated under the polarity transformation of the current through the coil The constantly changing polarity of the magnetic field interacts with the magnets to drive the drive shaft to rotate clockwise and counterclockwise periodically. The present invention uses a higher vibration frequency (usually higher than 30,000 times / minute), utilizes the position limiting and energy storage functions of the eccentric wheel, and adopts a magnet ring composed of a plurality of small magnets, and every two small magnets correspond to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com