Silane self-crosslinking halogen-free low-smoke flame-retardant elastic material and preparation method thereof

A low-smoke flame-retardant, silane crosslinking agent technology, applied in the direction of cable/conductor manufacturing, conductors, electrical components, etc., can solve the problems of high hardness and non-flame retardancy of materials, and achieve excellent processing performance, low cost, The effect of excellent mechanical properties and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

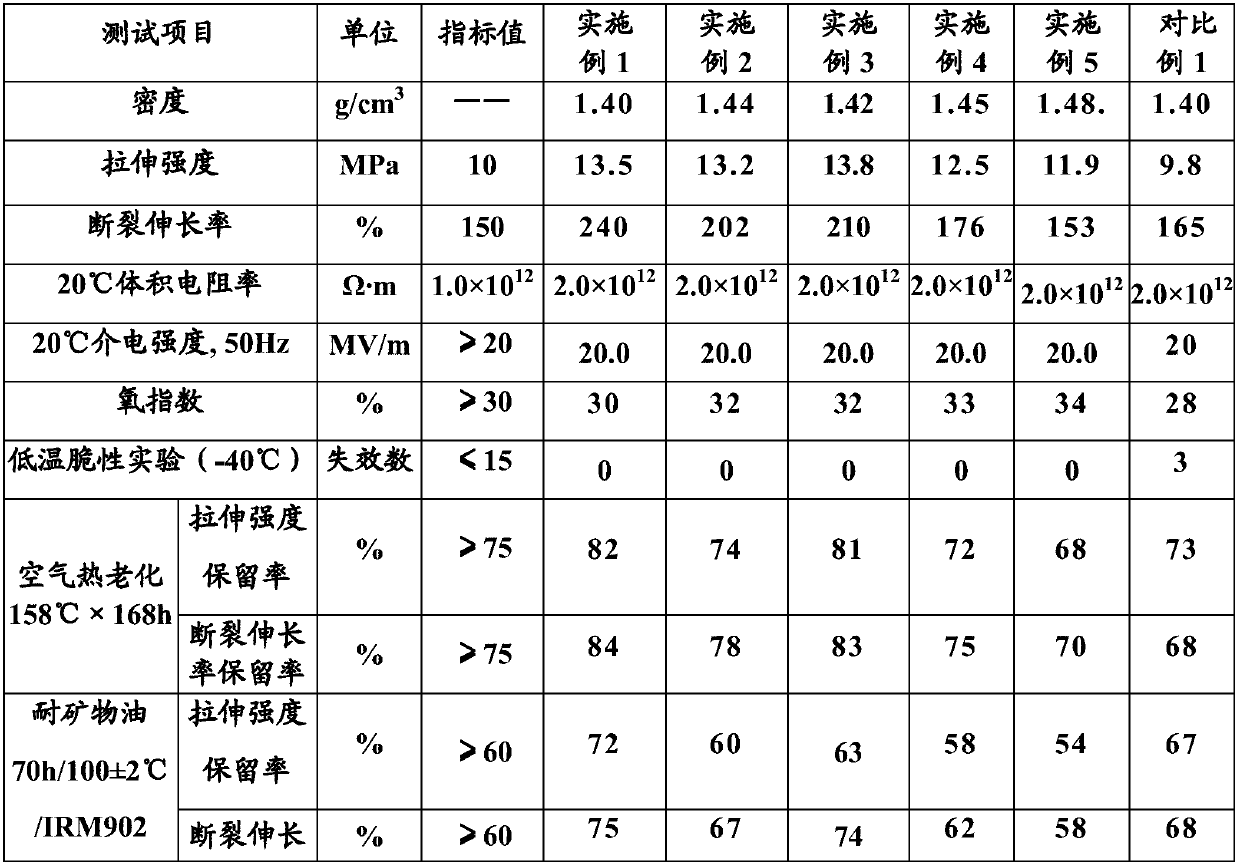

Examples

Embodiment 1

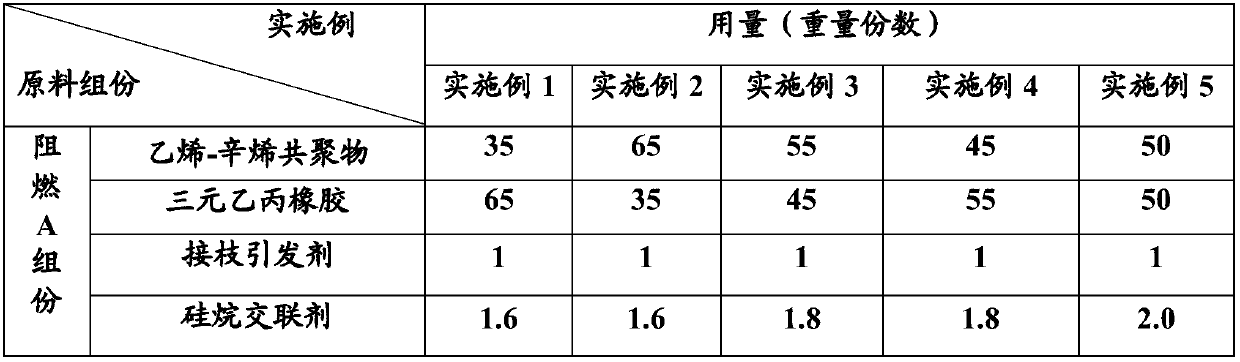

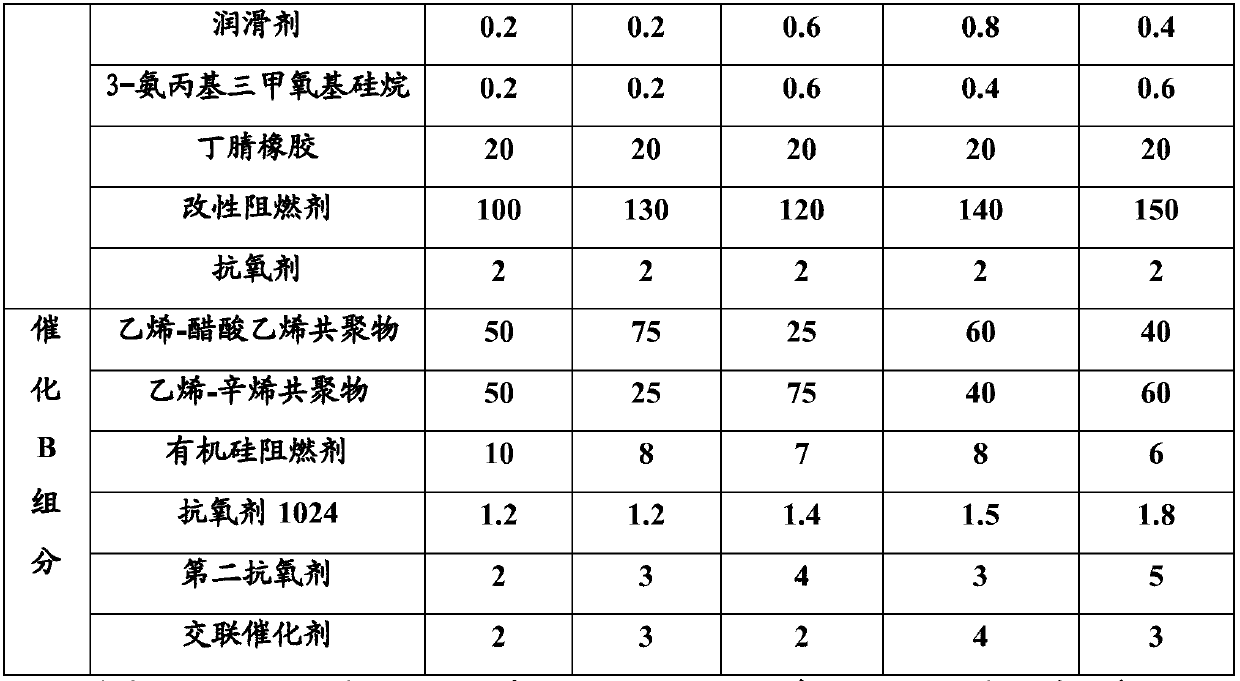

[0026] This example provides a method for preparing a silane self-crosslinking halogen-free low-smoke flame-retardant elastic material. The raw materials and dosages used are shown in Table 1, wherein:

[0027] The Mooney viscosity of EPDM rubber is 25, and the propylene content is 25wt%;

[0028] The melt index of ethylene-octene copolymer is 5.0, and the Shore A hardness is 75;

[0029] The lubricant is PPA, the antioxidant is antioxidant 300, the grafting initiator is DCP, and the silane crosslinking agent is vinyltrimethoxysilane.

[0030] The modified flame retardant is prepared by the following process: adding magnesium hydroxide to a high-speed mixer, and uniformly spraying into the ethanol solution of titanate coupling agent whose mass is 2% of the mass of magnesium hydroxide, titanic acid The content of the titanate coupling agent in the ethanol solution of the ester coupling agent is 40 wt%.

[0031] The second antioxidant comprises antioxidant 1010 and antioxidant...

Embodiment 2

[0039] This example provides a method for preparing a silane self-crosslinking halogen-free low-smoke flame-retardant elastic material. The raw materials and dosage thereof are shown in Table 1. The raw materials other than the modified flame retardant are the same as those in Example 1.

[0040] In this example, the modified flame retardant is prepared by the following process: adding magnesium hydroxide and aluminum hydroxide (weight ratio 2:1) into a high-speed mixer, and injecting a mass of magnesium hydroxide and hydrogen evenly under high-speed stirring 2% ethanol solution of titanate coupling agent based on the total mass of alumina, and the content of titanate coupling agent in the ethanol solution of titanate coupling agent is 40wt%.

[0041] The preparation process of the silane self-crosslinking halogen-free low-smoke flame-retardant elastic material is the same as that in Example 1.

Embodiment 3

[0043] This example provides a preparation method of silane self-crosslinking halogen-free low-smoke flame-retardant elastic material. The raw materials and dosage used are shown in Table 1. The raw materials other than the modified flame retardant and the second antioxidant are the same as those in the implementation Example 1 is the same.

[0044] In this example, the modified flame retardant is prepared by the following process: adding magnesium hydroxide and intumescent flame retardant (weight ratio 8:1) into a high-speed mixer, and injecting a mass of magnesium hydroxide evenly under high-speed stirring and 1% ethanol solution of titanate coupling agent based on the total mass of the intumescent flame retardant, and the content of titanate coupling agent in the ethanol solution of titanate coupling agent is 50wt%.

[0045] In this example, the second antioxidant comprises antioxidant 1010 and antioxidant 168 in a weight ratio of 2:1.

[0046] The preparation process of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com