Porous composite biological material containing multiple active ions and preparation method thereof

A technology of composite biomaterials and active ions, which is applied in the field of porous composite biomaterials and its preparation, can solve the problems of complex production process and lack of osteoinductive activity, and achieve good conductivity and promote the effect of new bone formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

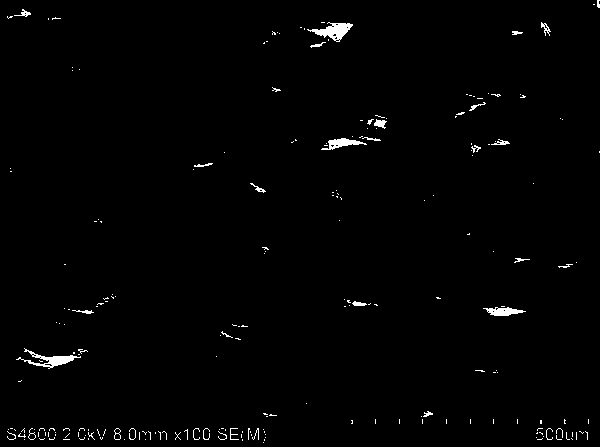

Image

Examples

Embodiment 1

[0058] Take 10 grams of cuttlebone porous bone ore support, 1.135 grams of manganese chloride, and 10 ml of water, prepare a solution to impregnate the cuttlefish bone porous bone ore support, and dry at 25 ° C for 72 hours; water 100 ml, phosphoric acid 9.6 ml, ammonium dihydrogen phosphate 2.4 g, glass Prepare the solution in the cup, add sodium hydroxide to adjust the pH to 4.0, completely immerse the cuttlebone porous bone ore support in the solution, and react under medium and low heat under microwave (frequency 2.45GHz, output power 270w) for 45 minutes, and dry at 60°C for 72 hour, get product 123101 (porous ceramic structure main body); get sodium metasilicate 1.2g, add water heating and dissolving into 5ml solution and tricalcium phosphate 0.8 gram, magnesium silicate 0.22 gram, strontium hydrogen phosphate 0.20 gram, potassium selenium polyphosphate Prepare 0.35g of slurry, divide 123101 into two equal parts, and take one part to spray with slurry; prepare 25ml of cal...

Embodiment 2

[0067] Cuttlebone porous bone mineral support 10 grams, zinc chloride 1.225 grams, water 10ml, prepared liquid impregnated cuttlefish bone porous bone mineral support, dried at 60°C for 2 hours; water 140ml, phosphoric acid 9.6ml, ammonium dihydrogen phosphate 2.4g, glass Phosphorus source solution was prepared internally, and potassium hydroxide solution was added to adjust the pH to 4.0. The cuttlebone porous bone ore support was completely immersed in the phosphorus source solution, and reacted under microwave at low heat (frequency 2.45GHz, output power 110w) for 180 minutes, and dried at 260°C After 6 hours, the product 123103 was obtained, and the product 123103 was divided into two parts; 3.2 g of sodium metasilicate was dissolved in water to form a 5.0 ml solution, and 0.8 g of tricalcium phosphate, 0.10 g of magnesium silicate, 0.125 g of strontium hydrogen phosphate, and 0.125 g of barium phosphate 0.2g, silver phosphate 0.1g, prepare a slurry, spray one of the produc...

Embodiment 3

[0078]Take 1.2g of sodium fluoride and 10ml of water to prepare a solution, impregnate cuttlebone porous bone mineral support (10g), and dry at 40°C for 8 hours; prepare a phosphorus source solution with 150ml of water, 6.0ml of phosphoric acid, and 0.6g of ammonium dihydrogen phosphate, and adjust the pH to 3. 0. Put the cuttlebone porous bone mineral support in the phosphorus source solution and react under microwave in a glass cup (frequency 2.45GHz, output power 420w) for 45 minutes; excellent color and good strength; dry at 100°C for 8 hours , to obtain the product 021501 (no ammonia smell); the product 021501 was divided into four equal parts, and one part of the 021501 product was taken, and 3.5ml of 28wt% potassium silicate solution, 0.9 grams of calcium hydrogen phosphate, 0.08 grams of strontium hydrogen phosphate, and 0.05 grams of magnesium phosphate were used , 0.32 grams of magnesium silicate, and 0.64 grams of calcium silicate to prepare a slurry, spray 21501 wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com