Vibration molding-based method for design of mix proportion of graded broken stones

A technology of mixing proportion design and grading gravel, applied in the direction of coagulation pavement, roads, roads, etc. paved on site, can solve the problem of semi-rigid base material cracking, early fatigue failure of semi-rigid pavement, and gradation that cannot be fundamentally eliminated. It can reduce the deflection of the road surface, improve the bearing capacity of the road, and improve the stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

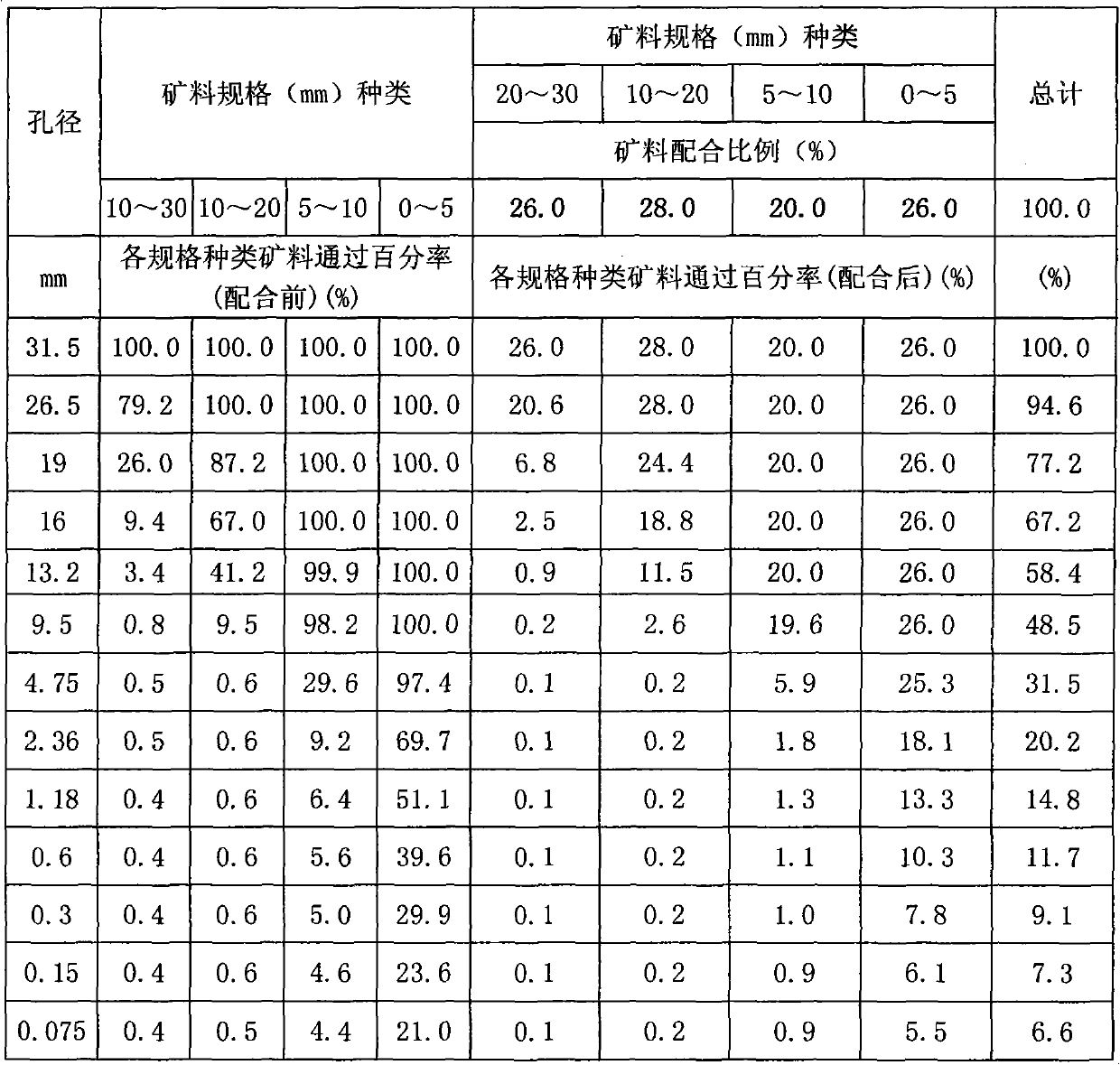

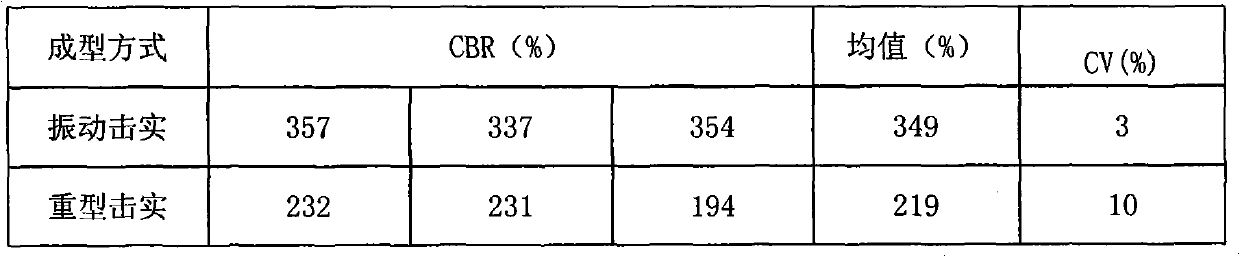

[0025] A mixing ratio design method based on vibration forming graded gravel, the specific steps are:

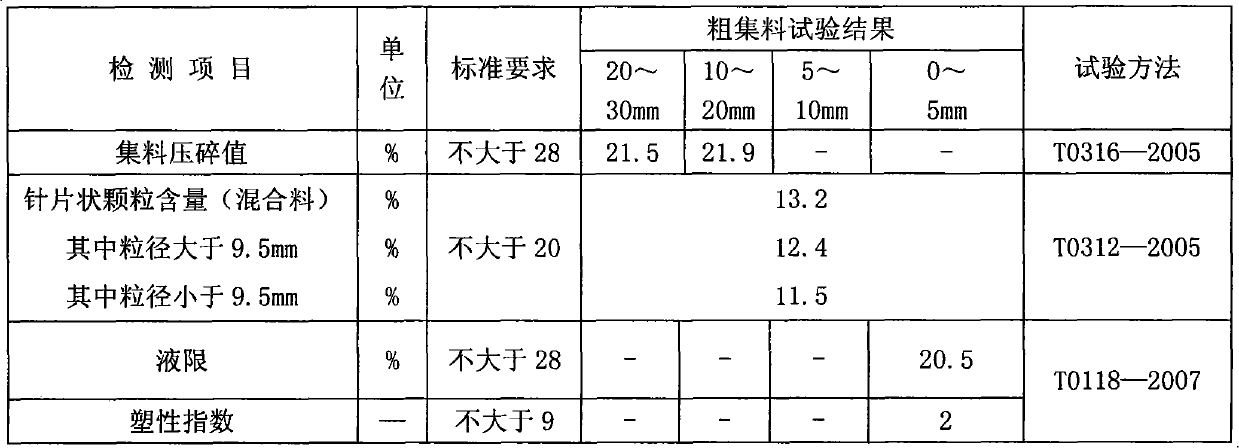

[0026] (1), raw material selection:

[0027] Select the aggregated crushed stone raw material: limestone is used as the base stone for graded crushed stone. Coarse aggregates in limestone have a certain degree of toughness, fine aggregates have a certain degree of plasticity, construction workability and water retention are better than other rock materials, easy to roll into shape, and not easy to segregate; at the same time, limestone powder is similar to limestone The powder can form strength after reacting with water, which is beneficial to the long-term use of the pavement structure. The graded crushed stone is rolled by an impact cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com