High strength glass fiber composition

A glass fiber and composition technology, applied in the field of high-strength glass fiber composition, can solve the problems of difficult temperature control, unfavorable glass drawing, difficult glass preparation, etc. Large-scale industrial production, the effect of realizing large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

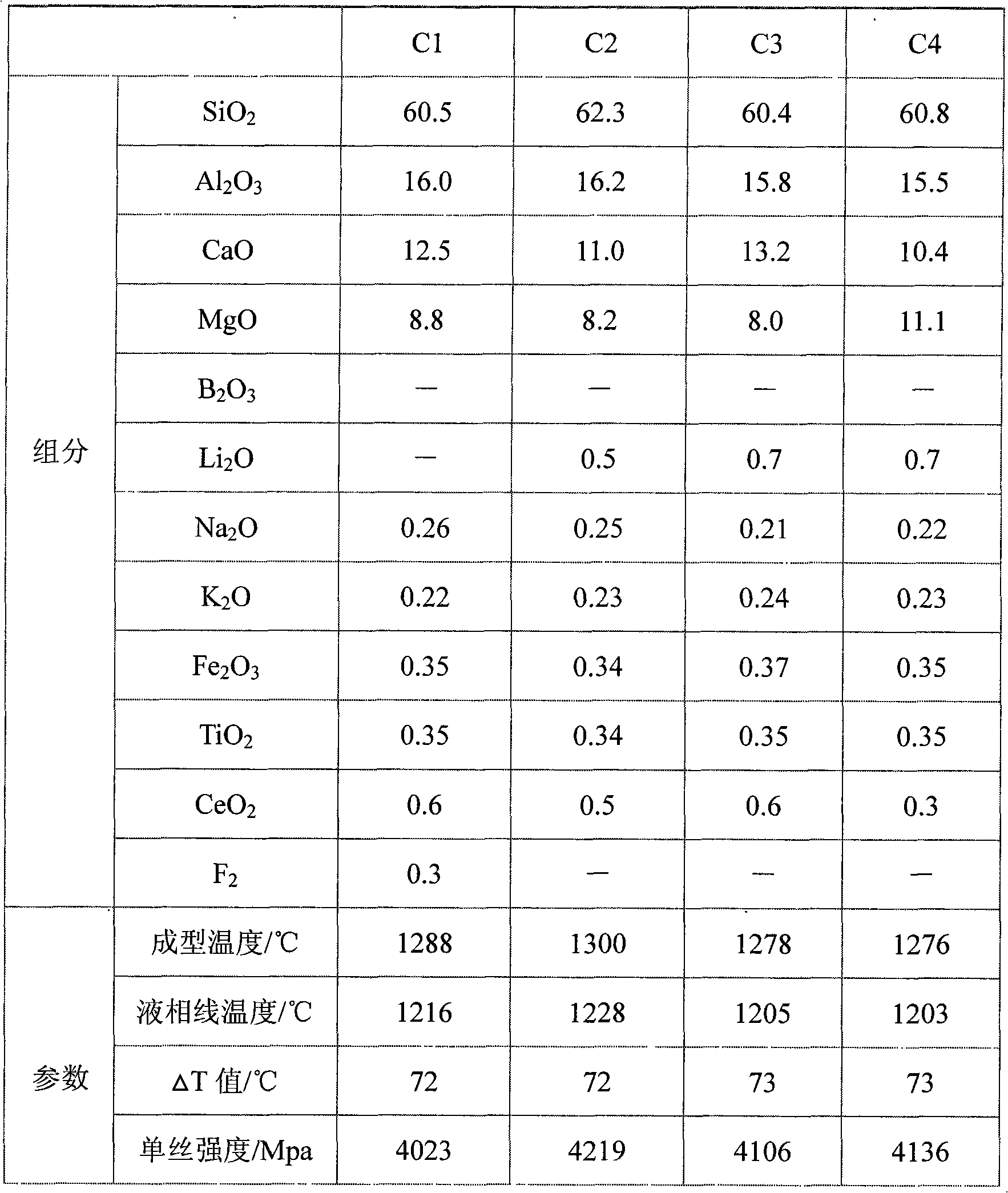

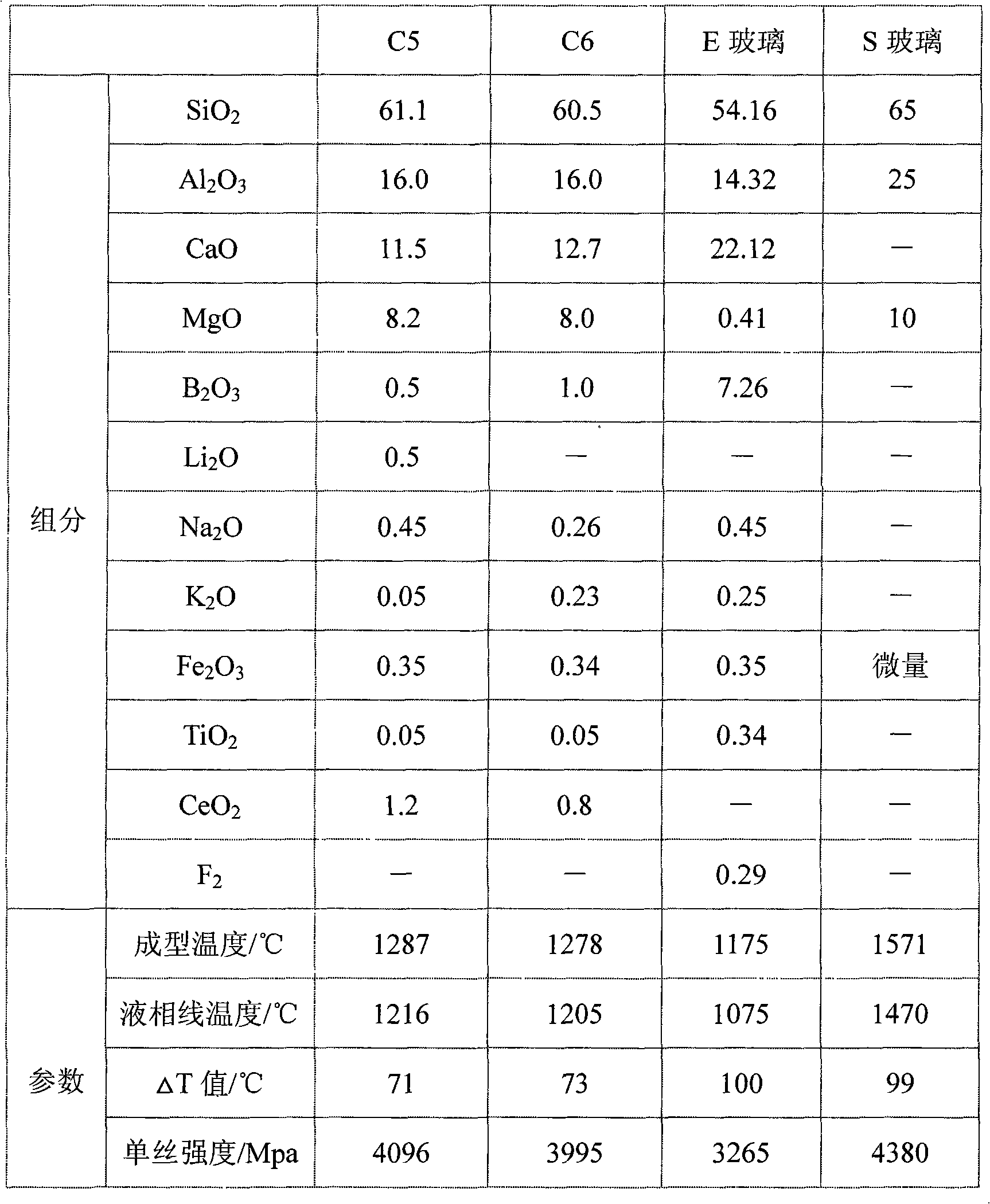

[0058] The technical solution of the present invention is specifically described below through examples, and the content of the present invention is not subject to any restriction by the following examples. Wherein the total content of the components in the examples is slightly less than 100%, it can be understood that the residual amount is a small amount of impurities or a small amount of components that cannot be analyzed.

[0059] The specific process of the embodiment of the present invention is as follows: each component can be obtained from appropriate raw materials, the various raw materials are mixed in proportion, so that each component reaches the final expected weight percentage, the mixed batch is melted and clarified, Then the molten glass is pulled out through the nozzle on the bushing to form glass fibers, which are drawn and wound to the rotating head of the wire drawing machine to form raw silk cakes or yarn clusters. These glass fibers can be further processe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com