Novel well logging method for the determination of catalytic activity

a technology of catalytic activity and well logging, which is applied in the field of well logging, can solve the problems of preventing the use of routine rock analysis, unable to meet the requirements of the basic structure of the well, and unable to meet the requirements of the well,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

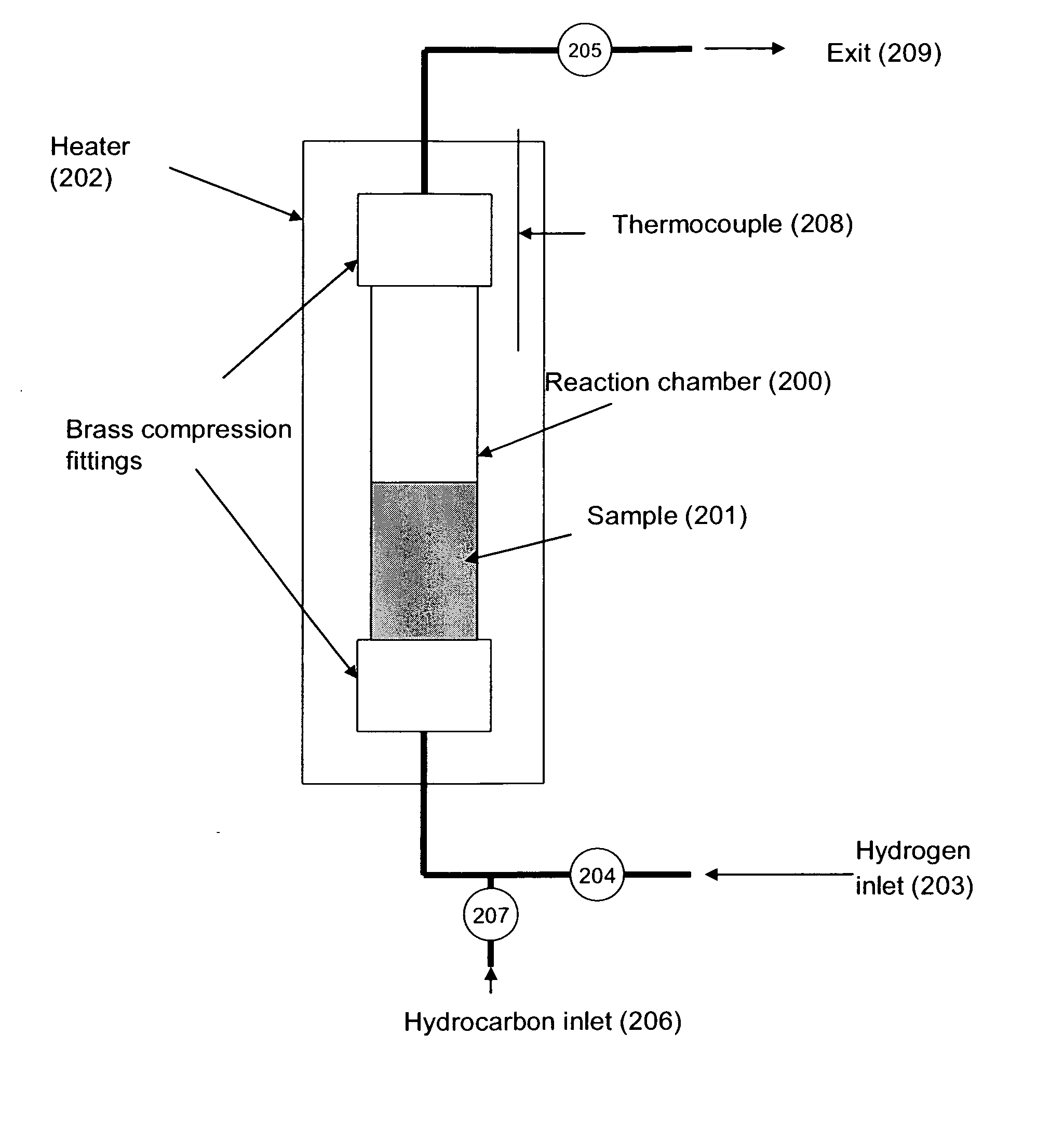

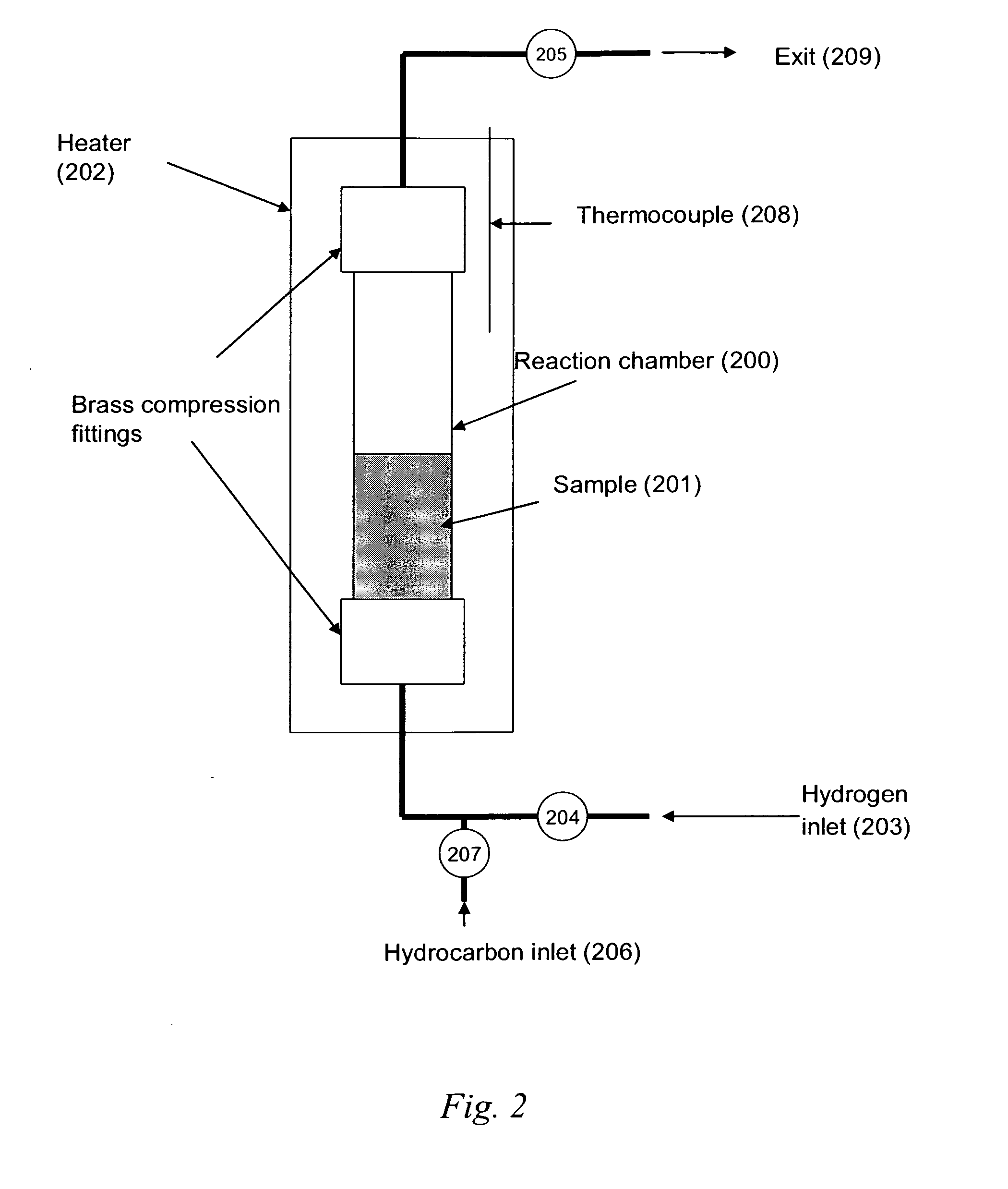

[0079] This Example serves to illustrate an embodiment by which the present invention can be used to assay sedimentary rock for oil-to-gas catalytic activity via the detection of catalytically-generated methane produced when a gaseous hydrocarbon species is contacted with said rock in the presence of hydrogen and under static exposure conditions.

[0080] A one gram sample of source rock (Miocene Monterey formation, California, taken from an outcrop on Venice Beach) was ground to 60 mesh and mixed with 5 cubic centimeters (cc) of sand under argon, and then heat-extracted at 300° C. for 30 minutes in flowing purified H2. Referring to reaction system 300 in FIG. 3, this mixture was sealed in a 10 cc brass reactor 301, then pressure vented five times at room temperature with a gas mixture of 97% H2 and 3% propane (C3), the gases purified by passage through commercial O2 scrubbers 302 (BOT-2 purchased from Agilent Technologies, Willington, Del.). Each pressure vent involved opening 3-way ...

example 2

[0081] This Example serves to illustrate an embodiment wherein the hydrocarbon material is a liquid and illustrates activity suppression by high concentrations of hydrocarbon and also illustrates the catalytic nature of the reaction.

[0082] A sample of Monterey rock (0.88 g) like that in Example 1, heat-extracted at 350° C. for 30 minutes in purified H2, was saturated with 100 micro liters of n-nonane (C9) and placed in Reactor 301. After five pressure-vents, as described in Example 1 using ultra pure H2 purified through oxygen scrubber 302 at room temperature, the reactor was closed (valves 306 and 307 closed) and heated to 240° C. for 30 minutes. The product, vented to FID (310) at 100° C. over about 30 minutes, indicated a catalytic activity of ˜3×10−6 g CH4 / (g rock hr). The reaction was repeated without adding additional n-nonane. The second product was ˜70 times that of the first with an activity of ˜2×10−4 g CH4 / (g rock hr). These results illustrate activity suppression in the...

example 3

[0083] This Example serves to illustrate an embodiment wherein the products are separated by gas chromatography. It also illustrates 1) that sedimentary rocks are catalytic in their natural state without added hydrogen or hydrocarbon, 2) that catalytic activity increases by a factor of 20 with H2 addition, 3) that catalytic activity is destroyed with the addition of oxygen-contaminated 1% pentane / hydrogen, and 4) that hydrocarbons in a natural source rock (and pentane) undergo insignificant thermal decomposition to thermal methane under reaction conditions. These results illustrate that sedimentary rocks are naturally catalytic in the conversion of hydrocarbons to natural gas.

[0084] Referring to FIG. 4, a Monterey source rock similar to those used above (0.25 g), except that it was not heat-extracted, was placed in reactor 401 and flushed with purified He (through oxygen scrubber 402) to vent (valves 403, 404, 405, and 406 open) as the reactor temperature was increased from room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com