Coated-type composite balance weight and manufacturing method thereof

A technology of a composite drop weight and a manufacturing method, which is applied to overhead lines and other directions, can solve the problems affecting the safety of catenary power supply and train running safety, the large volume of concrete weights, and the small size of iron weights, and achieves stable weight and frost resistance. Good performance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to solve the problems existing in the iron pendant and concrete pendant in the prior art, the present invention provides a coated composite pendant applied to the electrified railway catenary. The present invention will be further described in detail below in conjunction with the accompanying drawings and examples . It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

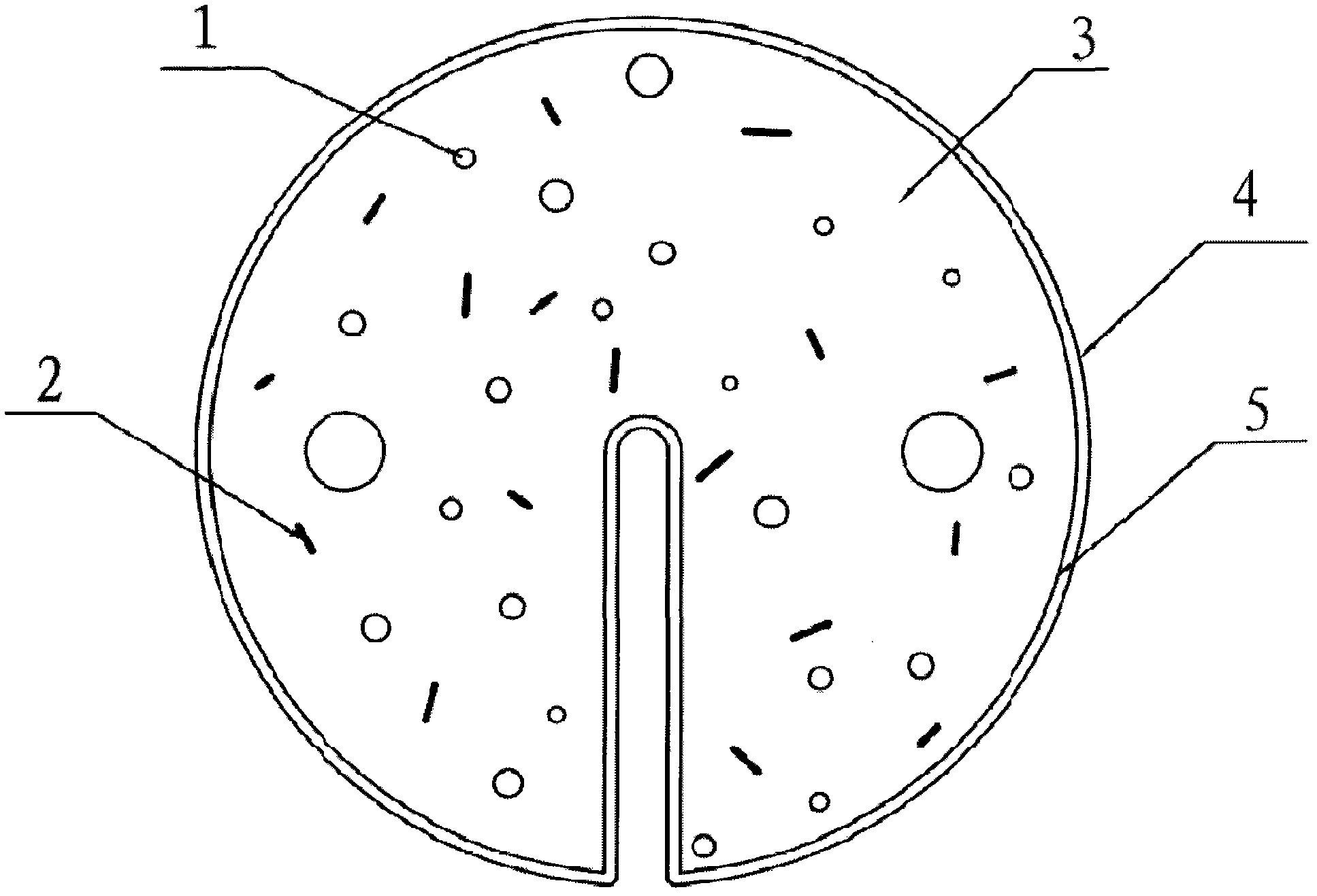

[0020] The clad composite pendant that the present invention relates to, such as figure 1 shown. Among them, (1) is the industrial slag, (2) is the reinforcing material, (3) is the inorganic adhesive, (4) is the cladding composite pendant shell, (5) is the cladding composite pendant body . The industrial slag can be iron ore, scale, barite or steel flower slag; the weight of the industrial slag accounts for 70-85% of the total mass; the weight of the inorganic binder accounts for the total mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com