Non-fired and non-autoclavedtitanium gypsum brick and preparation method thereof

A technology of gypsum bricks and titanium gypsum, which is applied in the field of non-burning and non-steaming titanium gypsum bricks and its preparation, can solve the problems of balance between production efficiency and production cost, failure to meet the requirements of comprehensive product performance, and expensive process equipment, etc., and achieve reduction The effect of production cost, compact structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

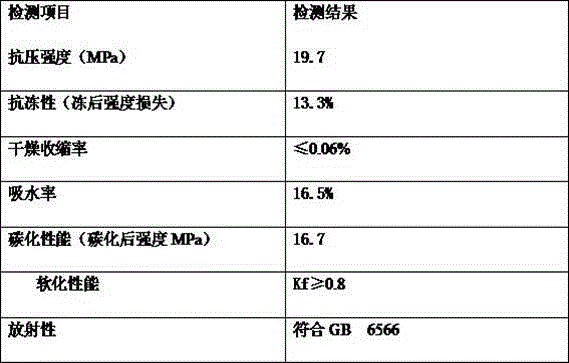

Embodiment 1

[0019] A non-burning and non-steaming titanium gypsum brick, including the following components in mass fraction: 24.5% titanium gypsum, 63% aggregate, 11.5% cement / mineral powder mixture and 1.0% additive, wherein: the additive is no The mixture of sodium sulfate water, alum and curing agent, the aggregate is one or more of industrial slag, gravel and river sand. Among the additives in this embodiment, anhydrous sodium sulfate is mainly used for coagulation, alum is used for disinfection and fermentation, and dihydrate gypsum is used as the solidifying agent. The raw materials of this additive are easy to prepare, and the cost is greatly reduced compared with the existing additives on the market. And the amount of addition is very small, which further reduces the cost of brick making.

[0020] The preparation method of the above-mentioned non-burning and non-steaming titanium gypsum brick comprises the following steps:

[0021] S1, extruding and stirring mud-type titanium gy...

Embodiment 2

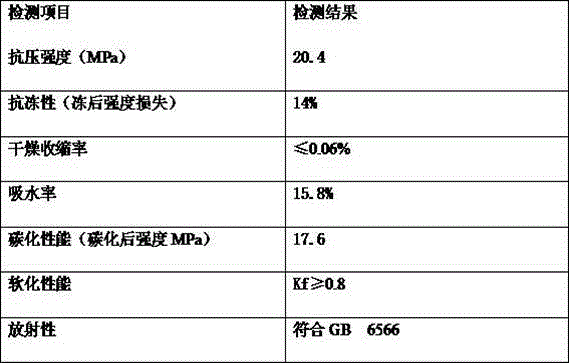

[0028] A non-burning and non-steaming titanium gypsum brick, including the following components in mass fraction: 32% titanium gypsum, 53.5% aggregate, 13.7% cement / mineral powder mixture and 0.8% additive, wherein: the additive is no The mixture of sodium sulfate water, alum and curing agent, the aggregate is one or more of industrial slag, gravel and river sand. Among the additives in this embodiment, anhydrous sodium sulfate is mainly used for coagulation, alum is used for disinfection and fermentation, and dihydrate gypsum is used as the solidifying agent. The raw materials of this additive are easy to prepare, and the cost is greatly reduced compared with the existing additives on the market. And the amount of addition is very small, which further reduces the cost of brick making.

[0029] The preparation method of the above-mentioned non-burning and non-steaming titanium gypsum brick comprises the following steps:

[0030] S1, extruding and stirring mud-type titanium gy...

Embodiment 3

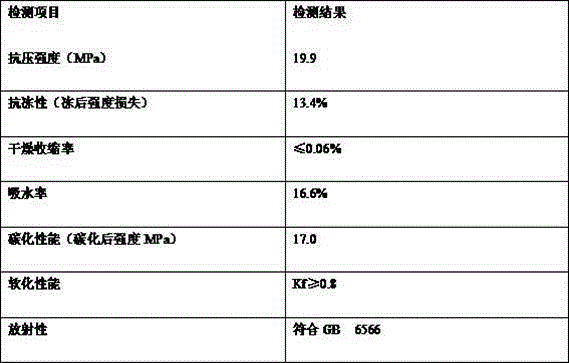

[0037] A non-burning and non-steaming titanium gypsum brick, including the following components in mass fraction: 26.5% titanium gypsum, 57.8% aggregate, 14.8% cement / mineral powder mixture and 0.9% additive, wherein: the additive is no The mixture of sodium sulfate water, alum and curing agent, the aggregate is one or more of industrial slag, gravel and river sand. Among the additives in this embodiment, anhydrous sodium sulfate is mainly used for coagulation, alum is used for disinfection and fermentation, and dihydrate gypsum is used as the solidifying agent. The raw materials of this additive are easy to prepare, and the cost is greatly reduced compared with the existing additives on the market. And the amount of addition is very small, which further reduces the cost of brick making.

[0038] The preparation method of the above-mentioned non-burning and non-steaming titanium gypsum brick comprises the following steps:

[0039] S1, extruding and stirring mud-type titanium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com