Roller disc grinding crusher

A technology of crushing mills and roller discs, which is applied in the direction of grain processing, etc., can solve the problems of low process efficiency, low crushing probability, and high crushing energy consumption, and achieve easy feeding and discharging, convenient operation and maintenance, and high crushing probability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

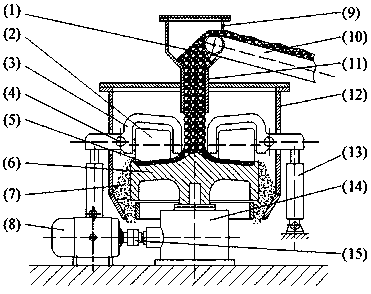

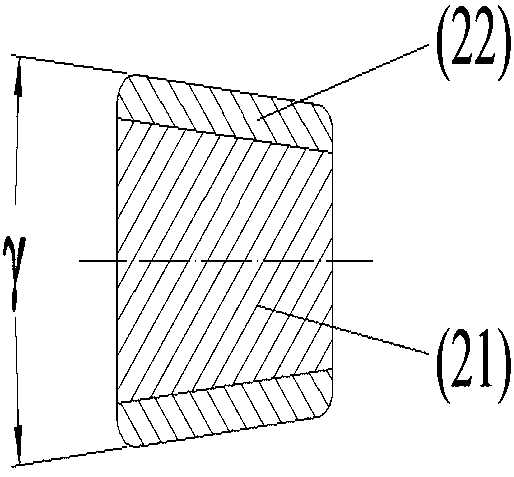

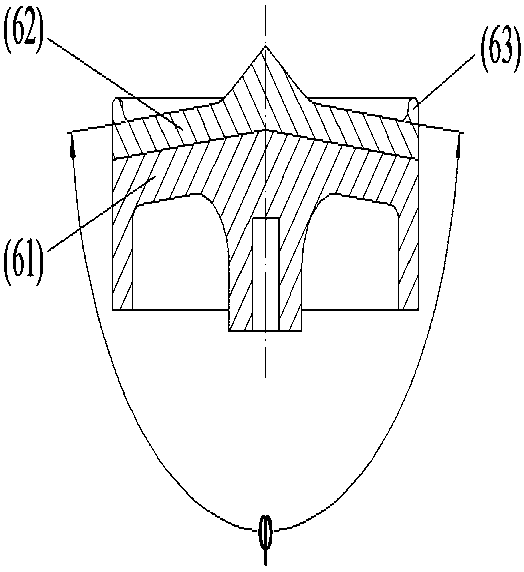

[0011] An embodiment of a roller disc grinder in the present invention, which consists of grinding roller (2), grinding roller frame (3), pivot (4), grinding disc (6), motor (8), feeding box (9), feeding machine (1), feeding pipe (1), body ⑿ , hydraulic cylinder ⒀, reducer ⒁ and coupling ⒂ and other components, such as figure 1 shown. The grinding table ⑹ is driven by the motor ⑻ and reducer ⒁ below, and rotates around the vertical axis; the grinding roller ⑵ is located above the grinding table ⑹, and is supported on the grinding roller frame ⑶ by a simple beam support, and is pivoted by the hydraulic cylinder ⒀ through the grinding roller frame ⑶. The shaft ⑷ is pressed on the millstone ⑹ as a fulcrum, and rotates under the drive of the millstone ⑹. The grinding roller (2) is composed of a roller body (21) and a roller sleeve (22). The outer surface of the roller sleeve (22) is also the surface of the grinding roller (2); the surface shape of the grinding roller (2) is trunc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com