Purification technique for HCI gas in high temperature flue gas

An alumina and chemical reaction technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of increasing flue gas humidity, serious secondary pollution, corrosion of downstream equipment, etc., and achieves simple structure of process equipment, Efficient removal and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The flue gas purification process of the present invention will be further described below in conjunction with the accompanying drawings.

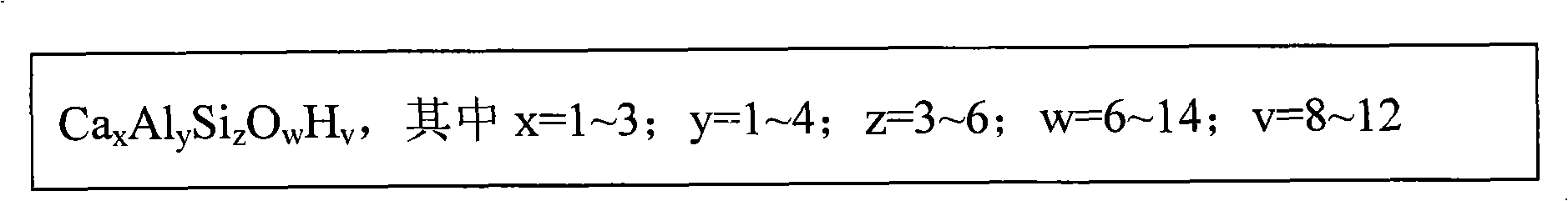

[0012] Fig. 1 is a molecular structure diagram of the core medicament Ca-Al-Si reactant in the present invention, and the variation range of the proportion of each element in the molecule.

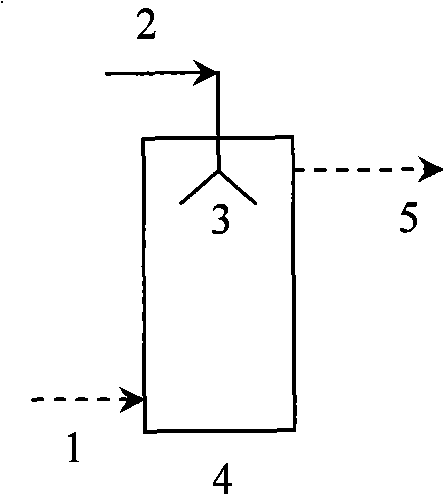

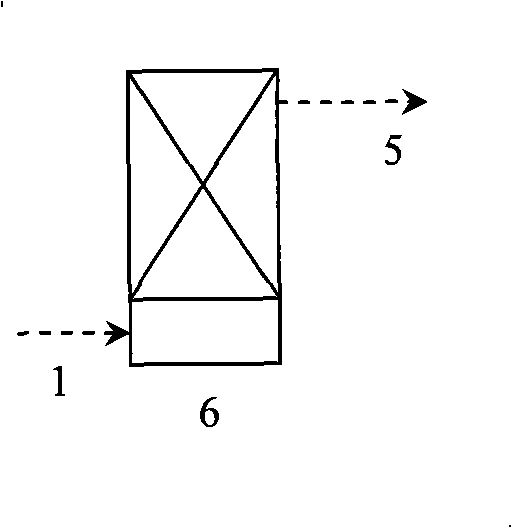

[0013] Figure 2 and Figure 3 are schematic process flow diagrams of the application example of the core agent Ca-Al-Si reactant in the present invention.

[0014] In the figure: 1. High temperature flue gas, 2. Ca-Al-Si reactant powder, 3. Chemical injector, 4. Chemical injection tower (P1), 5. Flue gas after hydrogen chloride removal, 6. Fixed bed reaction device (P2).

[0015] Specific implementation process:

[0016] (1) As shown in Figure 2: the high-temperature flue gas enters the P1 device, and the Ca-Al-Si reactant powder is added from the chemical injector. The residence time of the flue gas in P1 is 2 to 5 seconds, and the hydrogen ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com