Preparation of nano aluminum powder for conducting resin and storage method

A technology of nano silver powder and conductive adhesive, applied in the field of preparation and storage of precious metal nano silver powder, can solve the problems of low silver recovery rate, unfavorable scale production, low silver nitrate concentration, etc., achieve high silver recovery rate, improve recovery rate, production simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

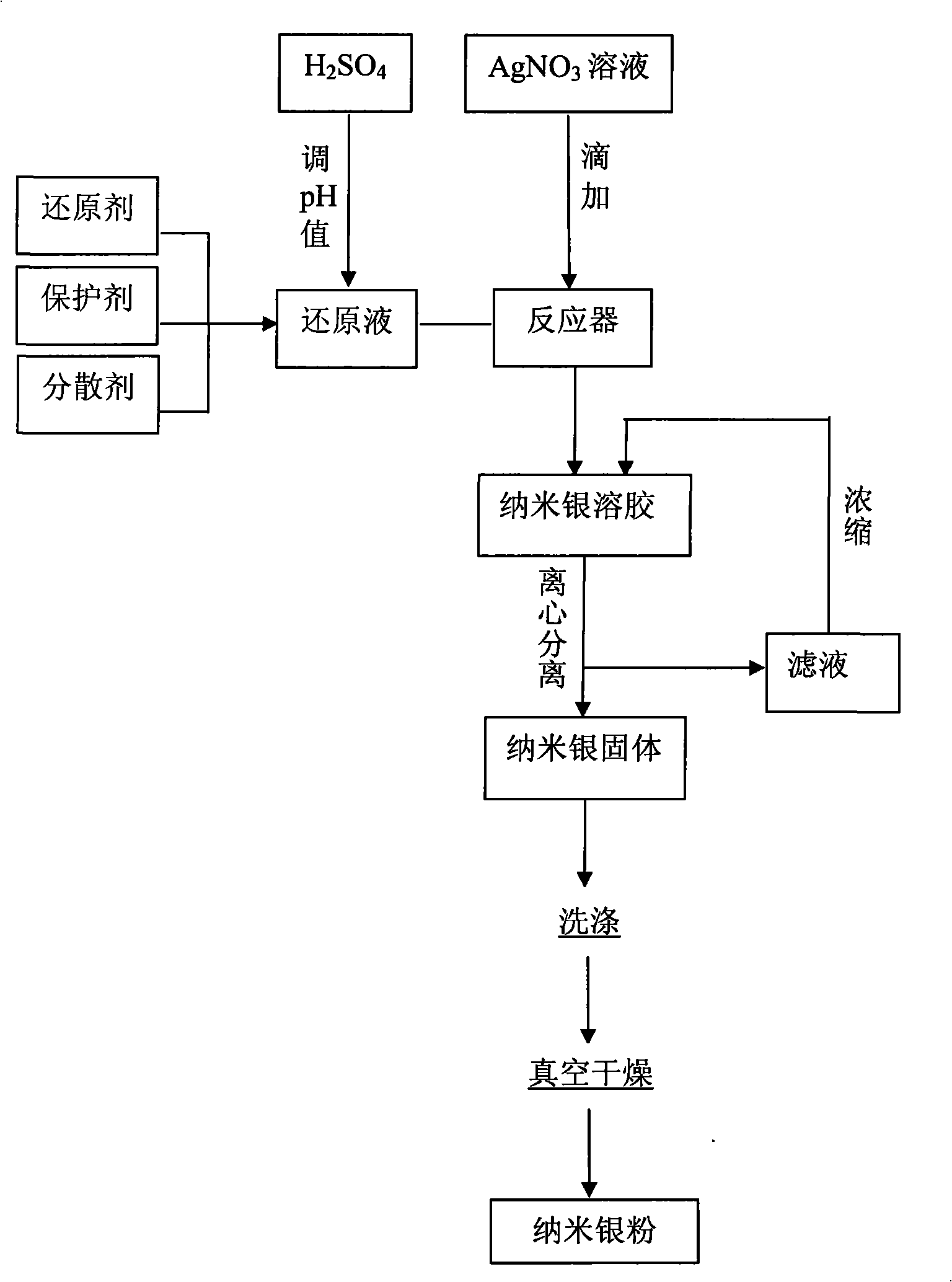

Method used

Image

Examples

Embodiment

[0036] Embodiment: used silver nitrate (analytically pure), its main component (%) is: AgNO 3 ≥99.8%, water insoluble ≤0.005%, chloride ≤0.001%, sulfate ≤0.004%, Fe≤0.0004%, Cu≤0.001%, Pb≤0.001%, hydrochloric acid non-precipitate ≤0.02%.

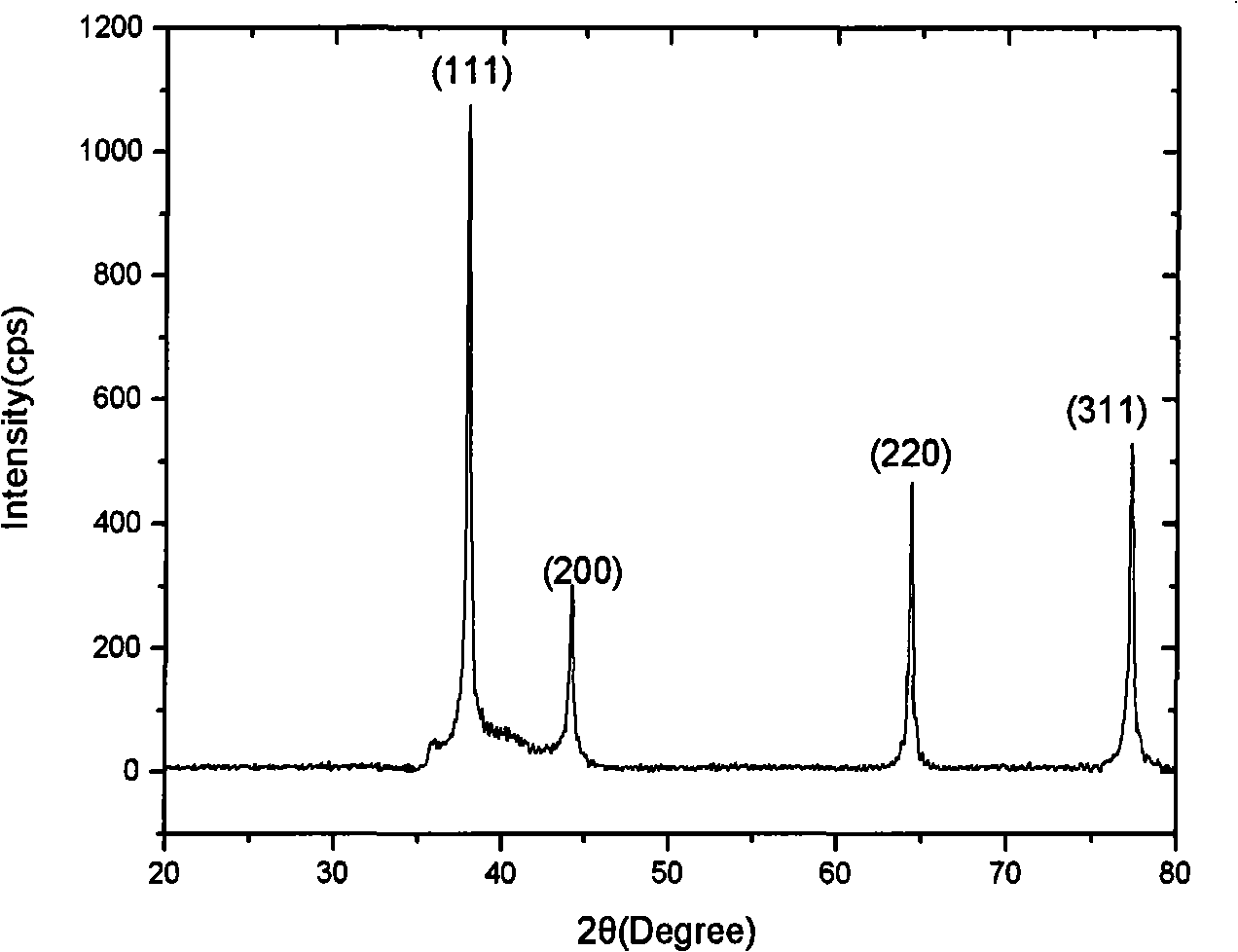

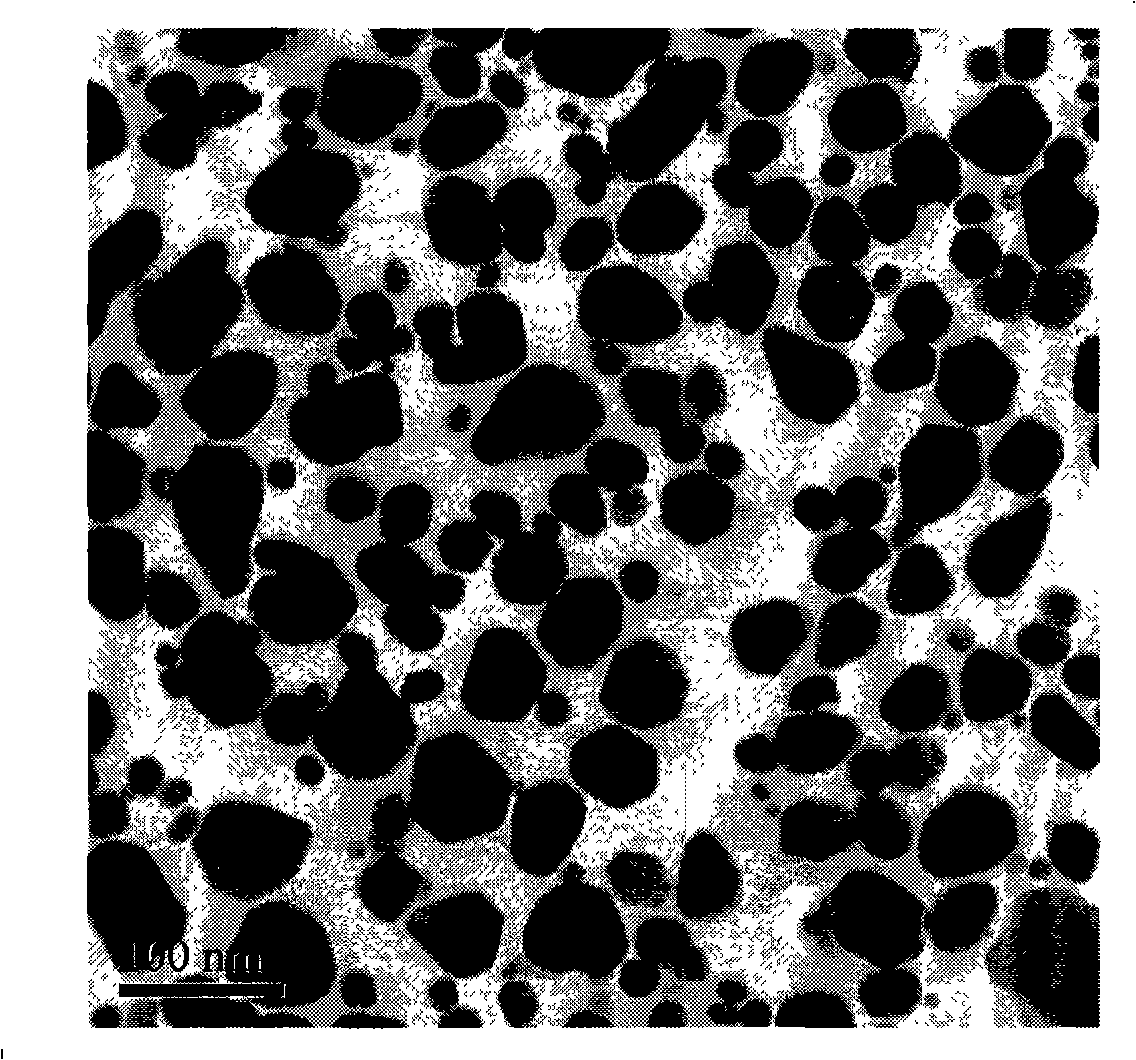

[0037] Weigh AgNO 3 3.4g dissolved in 20mL distilled water to make 1.0mol / L AgNO 3 oxidizing solution, and placed in a water bath at 40°C to keep the temperature constant; weigh 1.06g sodium hypophosphite, 3.4g polyvinylpyrrolidone (PVP), 0.43g sodium hexametaphosphate and dissolve them in 100mL distilled water to make a reducing solution, and add 2mL Sulfuric acid (c(H 2 SO 4 )=1.0mol / L) to adjust the pH value to 2; heat the reducing solution on a magnetic stirrer and stir to dissolve it completely, heat to 42°C to maintain a constant temperature, and mix AgNO at a rate of 20 drops / min under high-speed stirring 3 Add the oxidizing liquid dropwise; continue stirring for 30 minutes after the dropwise addition is complete to obtain a purpl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com