Preparation method of biodegradable mulching film

A biodegradation, mulching technology, applied in the fields of botanical equipment and methods, plant protection, plant protection cover, etc., can solve the problems of excessive degradation time, incomplete degradation, poor mechanical properties and water resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

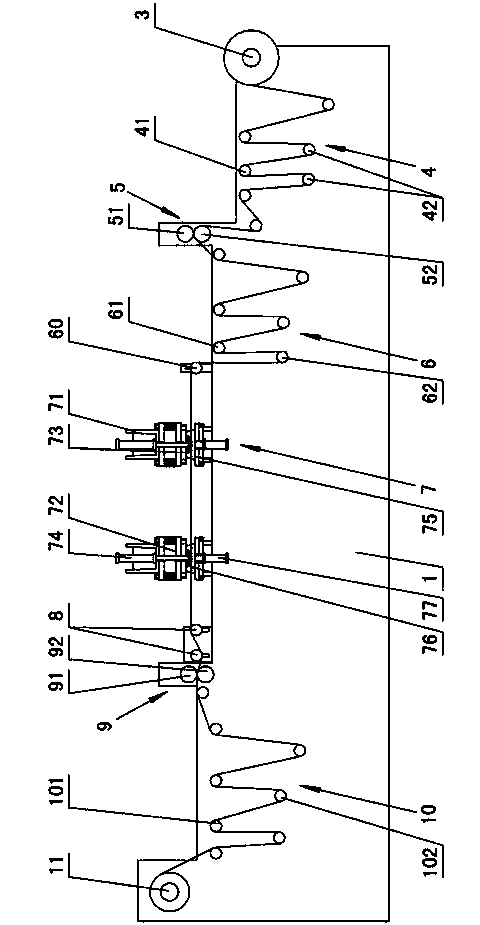

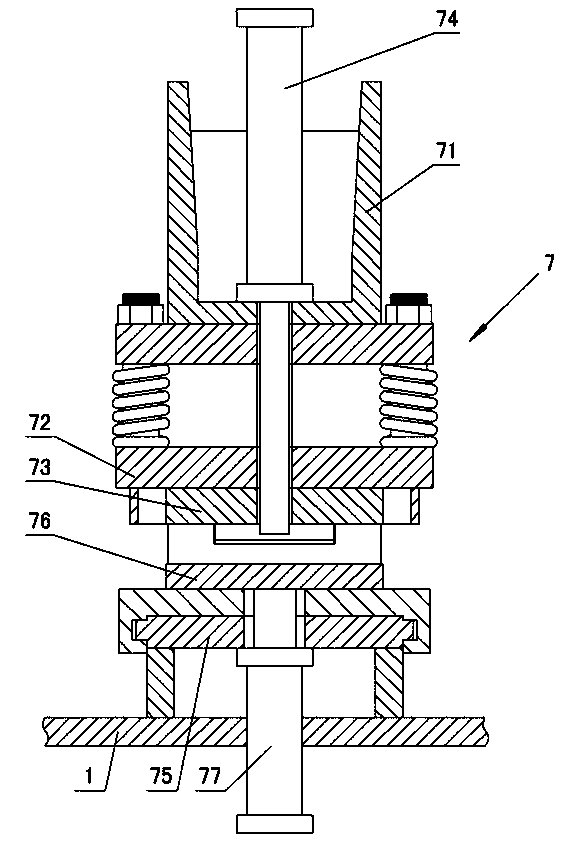

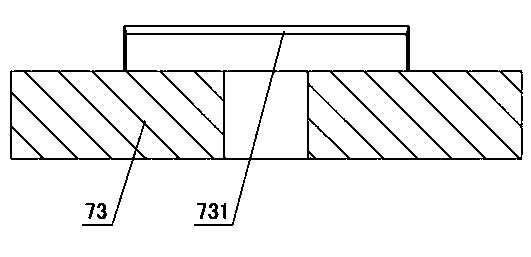

[0042] The present invention relates to a kind of preparation method of biodegradable film, such as figure 1 — Image 6 As shown, it is characterized by:

[0043] 1. Ingredients according to the weight ratio, take: polyethylene: 55~60 parts;

[0044] Tapioca starch: 17~20 parts;

[0045] Corn starch: 18~22 parts;

[0046] Multi-component bio-degradant: 5~10 parts;

[0047] Described polyethylene, by weight component ratio:

[0048] 7050: 68~90 copies;

[0049] 1F7B: 10~32 copies;

[0050] Described multi-component bio-relief agent, the component ratio by weight:

[0051] Cross-linking agent: 40~80 parts;

[0052] Degradation accelerator: 20~40 parts;

[0053] The cross-linking agent includes one or any combination of two of di-tert-butylperoxycumene, sodium hexametaphosphate, sodium trimetaphosphate or sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com