Mineral dressing additive for gold mine and preparation method thereof

A technology of additives and gold mines, applied in flotation, solid separation, etc., to achieve the effect of short process flow, low production cost and increased value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

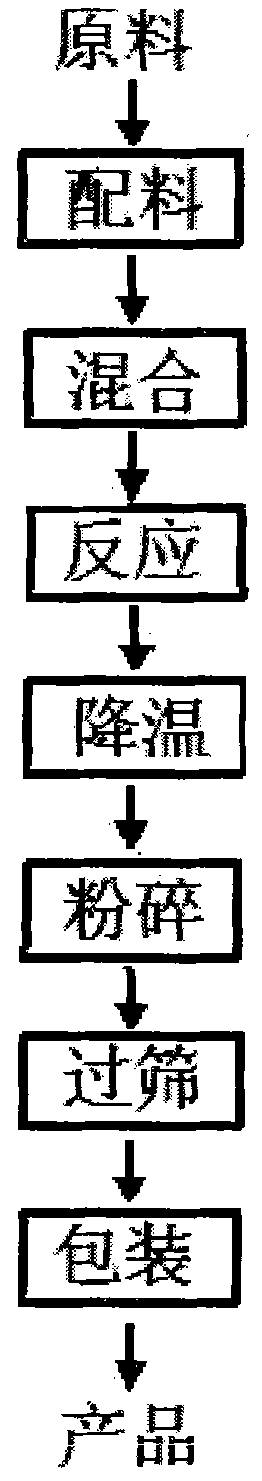

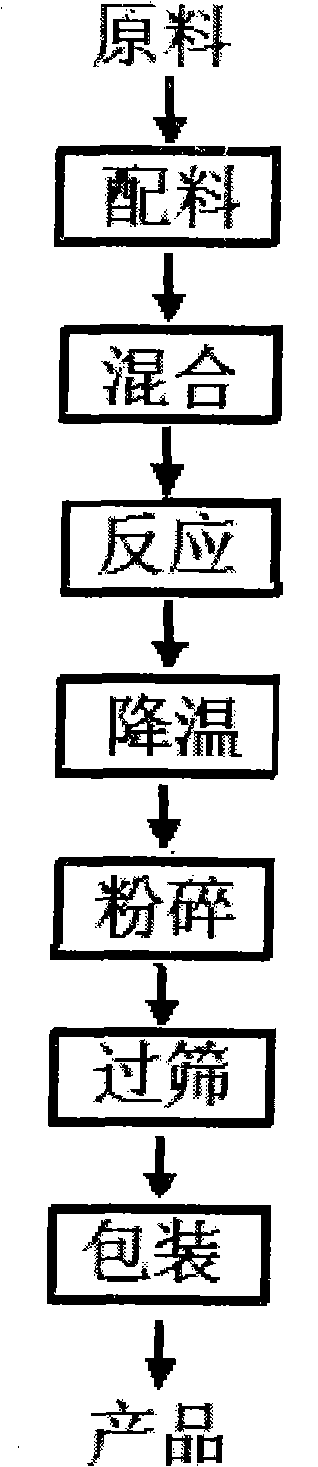

Image

Examples

preparation Embodiment 1

[0029] The raw material composition and weight fraction are: urea is 40 parts, sodium hexaphosphate is 8 parts, sodium sulfide is 7 parts, sodium bromide is 2 parts, sodium ferrocyanide is 20 parts, soda ash is 35 parts and caustic soda is 6 servings.

[0030] Preparation method: Weigh the raw materials according to the proportion, and add them into the mixer to mix the ingredients together. After mixing evenly, add them to the stainless steel reaction pot and react at 800-900°C for 1.5 hours, then cool down to 30°C and pulverize them with a pulverizer, and then pass through Sieve through a 20-mesh vibrating sieve, and finally pack to obtain mineral processing additive products.

[0031] This product was tested in a gold mine in Guangxi from June to August 2010. Compared with the original cyanidation process, the gold recovery rate increased by 23.1%, and the aqueous solution added with this product used in production is non-toxic for animals to drink.

preparation Embodiment 2

[0033] The raw material composition and weight fraction are: 45 parts of urea, 5 parts of sodium hexaphosphate, 10 parts of sodium sulfide, 20 parts of sodium ferrocyanide, 40 parts of soda ash and 8 parts of caustic soda.

[0034] Preparation method: Weigh the raw materials according to the proportion, and add them into the mixer to mix the ingredients. After mixing evenly, add them to the stainless steel reaction pot and react at 650-750°C for 2 hours, then cool down to 40°C and grind them with a pulverizer. Sieve through a 20-mesh vibrating sieve, and finally pack to obtain mineral processing additive products.

[0035] This product was tested in a gold mine in Guangxi from June to August 2010. Compared with the original cyanidation process, the gold recovery rate increased by 29.6%, and the aqueous solution added with this product used in production is non-toxic for animals to drink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com