Silver-loaded nano-titanium dioxide/polrvinyl chloride membrane and preparation method thereof

A nano-titanium dioxide and polyvinyl chloride membrane technology is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effects of easy realization, improved surface energy, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

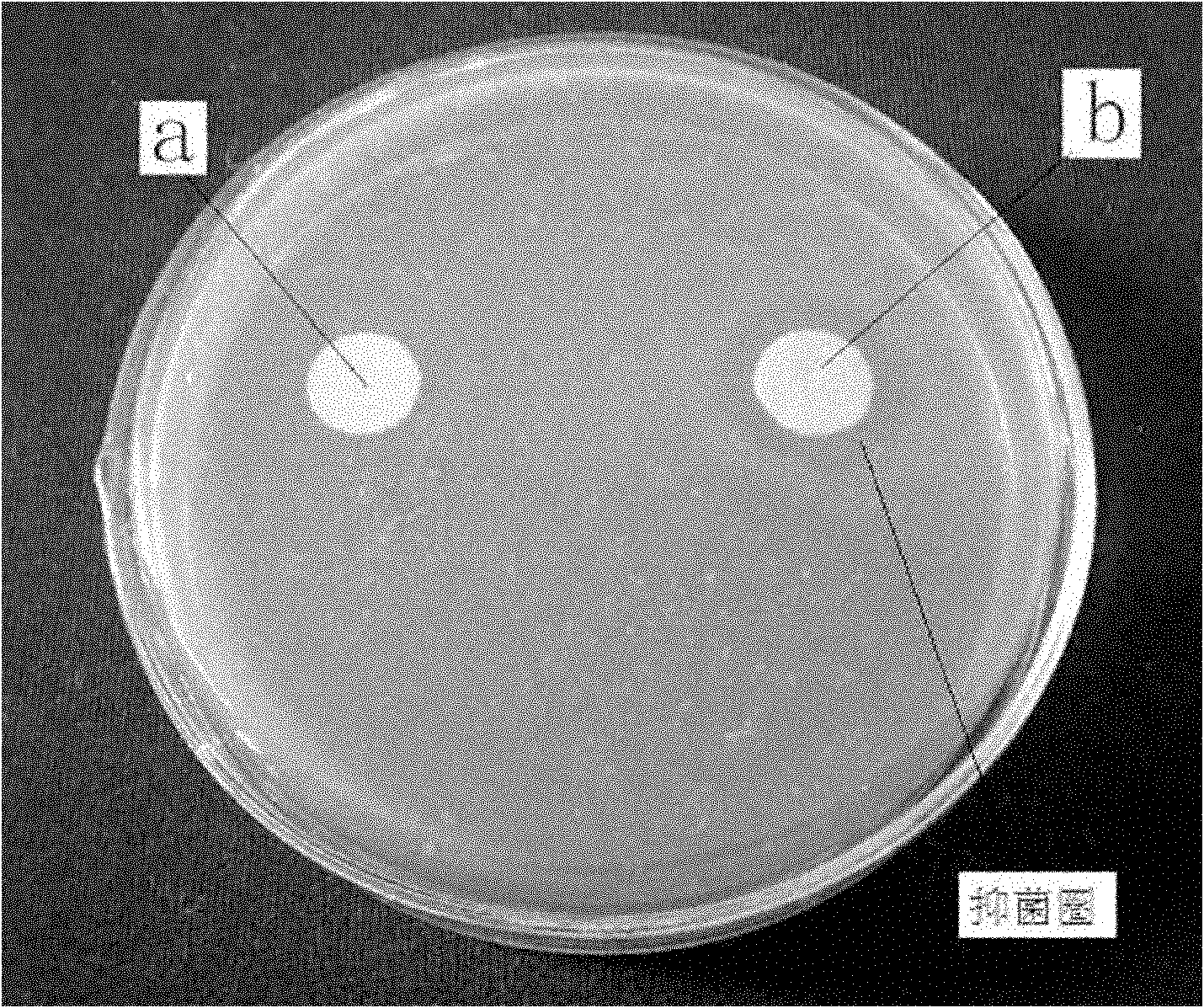

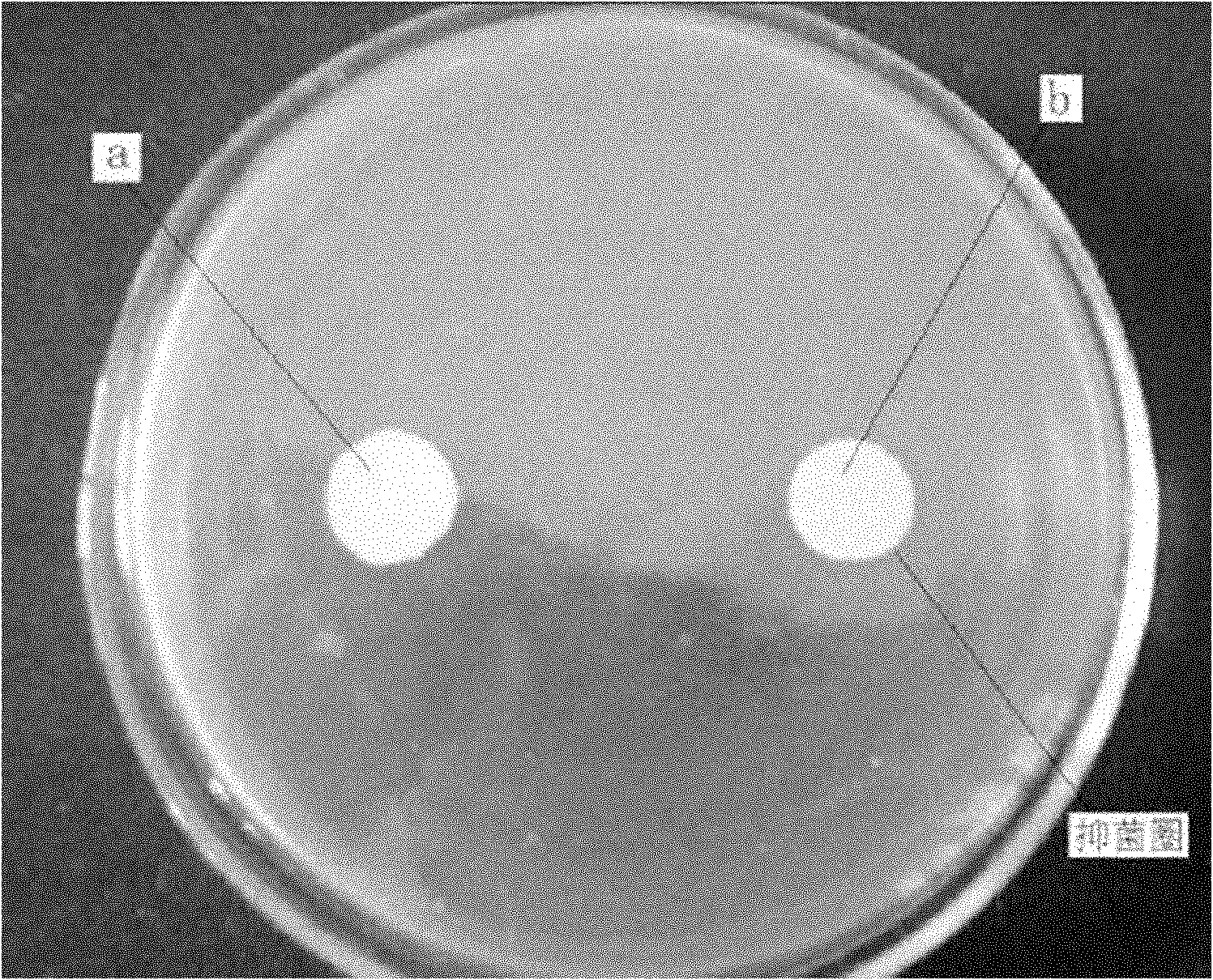

Image

Examples

Embodiment 1

[0064] Dissolve 3.5 grams of polyvinyl chloride (PVC) in 35 grams of N-N dimethylacetamide solvent, and after it is completely dissolved, add 0.5 grams of silver-loaded nano-titanium dioxide powder evenly in the process of stirring, and immediately add 0.5 grams of Dispersant sodium hexametaphosphate, finally add 1.5 grams of pore-forming agent polyvinylpyrrolidone (PVP), and stir evenly for 24 hours to make the silver-loaded nano-titanium dioxide particles evenly dispersed in the solution. Cast film on glass by L-S phase inversion method at 25°C and 65% humidity; after volatilization for 50 seconds, put it into 20% ethanol coagulation solution, after the film peels off automatically, take the glass plate out of the coagulation solution, and the film remains Soak in the coagulation solution for 24 hours, rinse the membrane with distilled water, and prepare the silver-loaded nano-titanium dioxide modified polyvinyl chloride flat separation membrane.

[0065] The characteristics...

Embodiment 2

[0067] Dissolve 3.5 grams of polyvinyl chloride (PVC) in 35 grams of N-N dimethylacetamide solvent, and after it is completely dissolved, add 0.5 grams of silver-loaded nano-titanium dioxide powder evenly in the process of stirring, and immediately add 0.486 grams of Dispersant sodium hexametaphosphate, finally add 0.5 grams of pore-forming agent polyvinylpyrrolidone (PVP), and stir evenly for 24 hours to make the silver-loaded nano-titanium dioxide particles evenly dispersed in the solution. Cast film on glass by L-S phase inversion method at 25°C and 65% humidity; after volatilization for 50 seconds, put it into 20% ethanol coagulation solution, after the film peels off automatically, take the glass plate out of the coagulation solution, and the film is Soak in the coagulation solution for 24 hours, rinse the membrane with distilled water, and prepare a silver-loaded nano-titanium dioxide modified polyvinyl chloride flat separation membrane.

[0068] The characteristics of t...

Embodiment 3

[0070] Dissolve 5.0 grams of polyvinyl chloride (PVC) in 35 grams of N-N dimethylacetamide solvent, and after it is completely dissolved, add 0.5 grams of silver-loaded nano-titanium dioxide powder evenly in the process of stirring, and immediately add 0.5 grams of Dispersant sodium hexametaphosphate, finally add 1.5 grams of pore-forming agent polyvinylpyrrolidone (PVP), and stir evenly for 24 hours to make the silver-loaded nano-titanium dioxide particles evenly dispersed in the solution. Cast film on glass by L-S phase inversion method at 25°C and 65% humidity; after volatilization for 50 seconds, put it into 20% ethanol coagulation solution, after the film peels off automatically, take the glass plate out of the coagulation solution, and the film is Soak in the coagulation solution for 24 hours, rinse the membrane with distilled water, and prepare a silver-loaded nano-titanium dioxide modified polyvinyl chloride flat separation membrane.

[0071] The characteristics of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com