Rubber modified asphalt warm-mixing agent, preparation method and application

A warm mix agent and asphalt technology, applied in building thermal insulation materials, climate change adaptation, building components, etc., can solve the problems of asphalt aging, high production temperature, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Warm mixing agent preparation process: add 100 parts of water to the container at 65°C, and then add the following substances in order under stirring conditions: 15 parts of fatty alcohol sodium sulfate, 20 parts of palmitic acid, 20 parts of oleic acid, dodecane 8 parts of sodium phenylsulfonate, 12 parts of cetyltrimethylammonium chloride, and 15 parts of imidazoline cationic surfactant ODD were stirred for 15 minutes to obtain a warm mixing agent.

Embodiment 2

[0015] For rubber asphalt, prepare according to the existing patent "A Waste Rubber Powder Modified Asphalt and Its Preparation Method" (Patent No. 200810102378.7), wherein the base asphalt is made of Binzhou Heavy Jiao 90 # Asphalt, 60 purpose waste rubber powder addition is 20%, makes rubber asphalt, then adds embodiment 1 warm mix agent in rubber asphalt, the addition quality of warm mix agent accounts for 2-5% of matrix asphalt quality, stirs 10- The sample was obtained after 15 minutes, its viscosity is shown in Table 1 below, and the three major index tests are shown in Table 2.

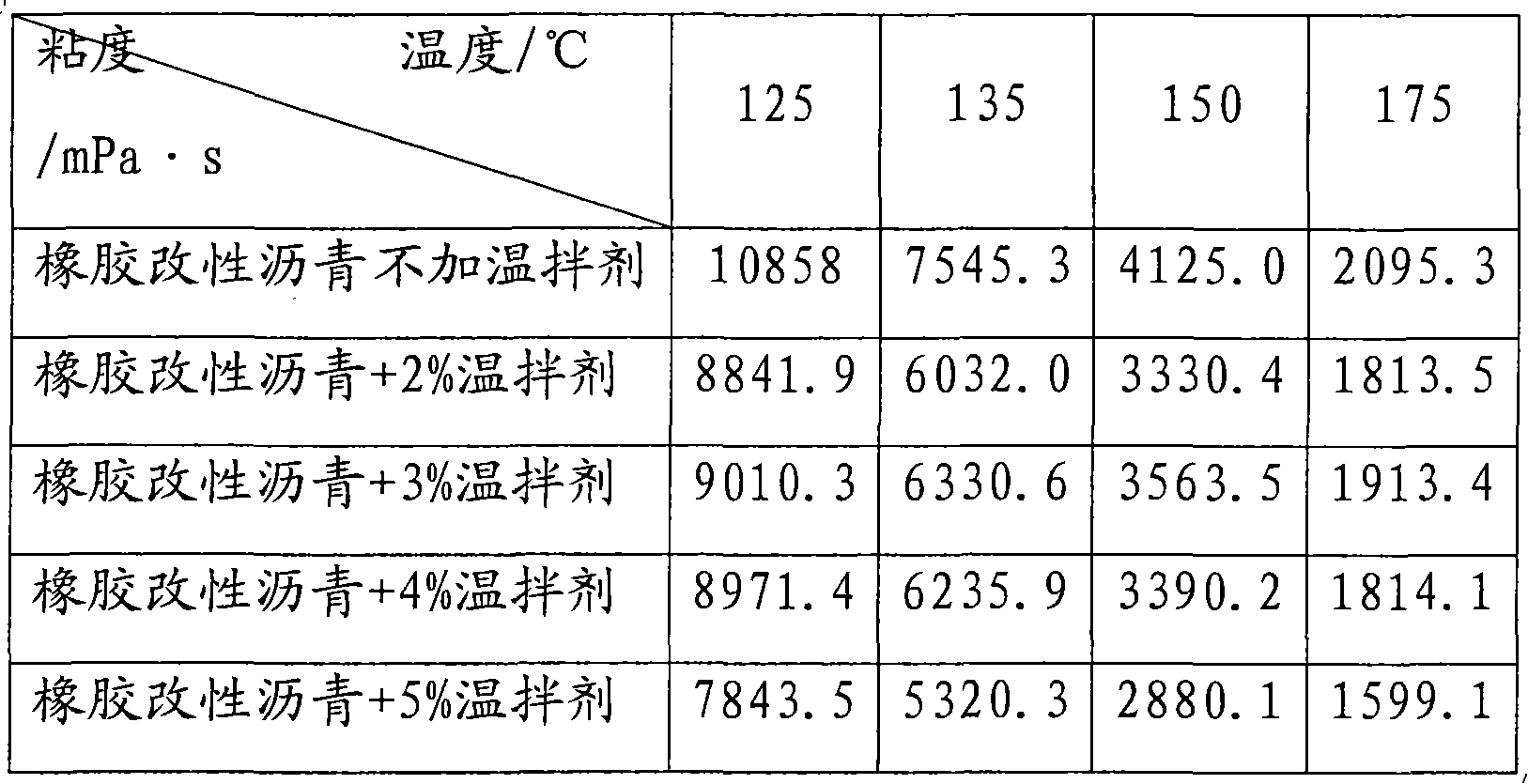

[0016] Table 1 Comparison of rubber asphalt viscosity at different temperatures and different volumes

[0017]

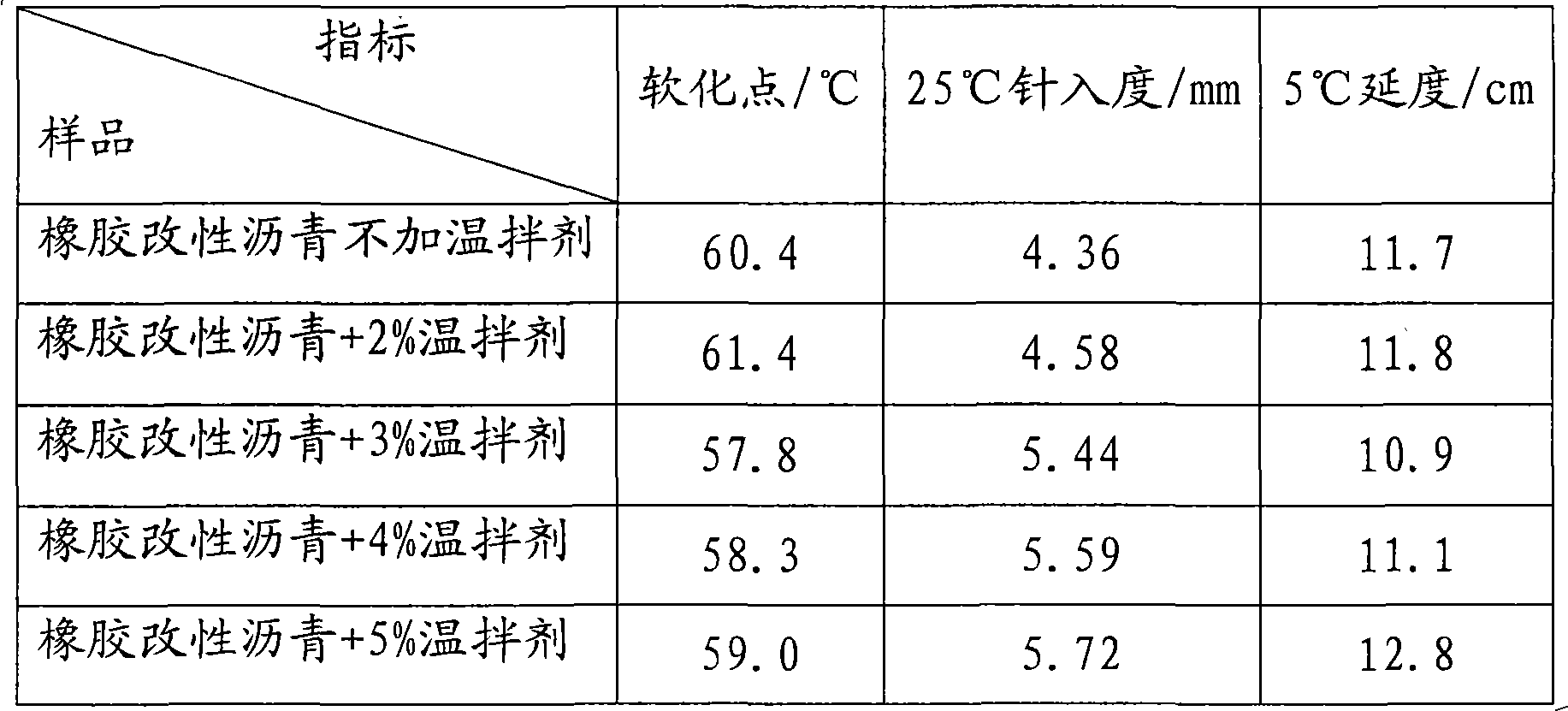

[0018] Table 2 The three major indicators are tested as follows

[0019]

[0020] From the analysis of the above test results, the addition of warm mix agent will significantly reduce the viscosity of rubber-modified asphalt, and the effect will be obvious with the increase of...

Embodiment 3

[0022] Use base asphalt, add 5% of the warm mix agent of Example 1, and stir at 160°C for 15 minutes to obtain the following viscosity comparison, see Table 3, and see Table 4 for the three major index tests.

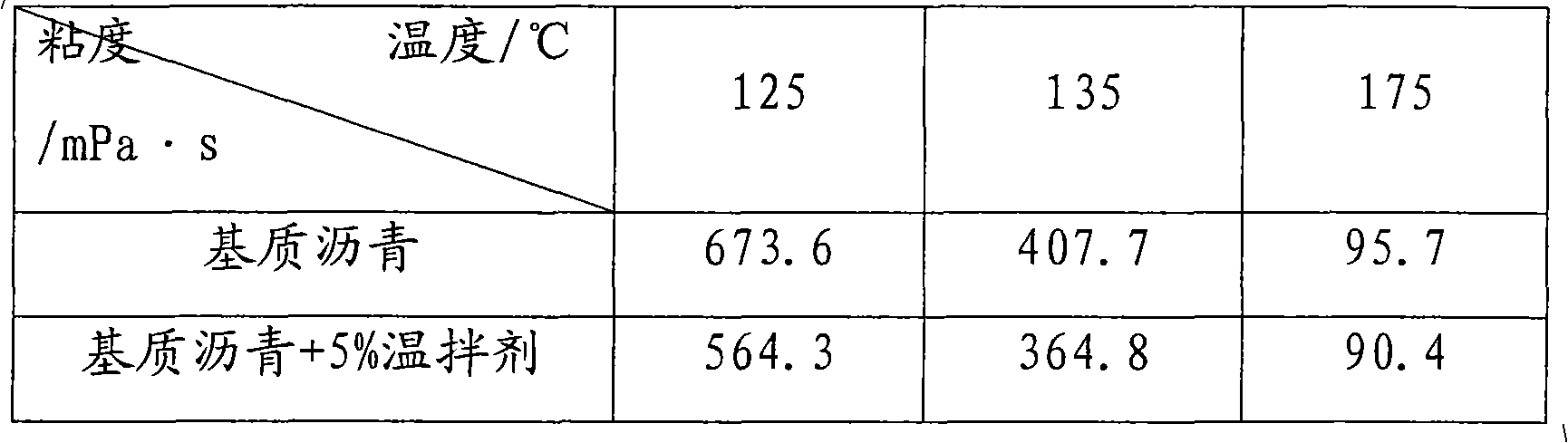

[0023] Table 3 Viscosity comparison of base asphalt and base asphalt with warm mix agent

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com