Preparation method for electroactive aniline oligomer-modified graphene

An oligomer and graphene technology, applied in the field of preparation of electroactive aniline oligomer modified graphene, can solve the problems of insoluble polyaniline, poor processing, complex structure, etc. The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

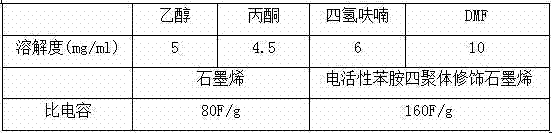

Examples

Embodiment 1

[0019] Mix 2.5g of natural graphite, 2.5g of sodium nitrate and 100ml of sulfuric acid, keep the ice bath at 0~5℃, slowly add 7.5g of potassium permanganate, stir continuously for 1h, add deionized water, and heat to maintain the temperature at 95~ Stir at 100°C for 15-30 minutes, then add 100ml of ionized water and hydrogen peroxide, and add the hydrogen peroxide dropwise until the solution stops bubbling. Suction filter and wash with 160ml of 5% hydrochloric acid aqueous solution (the molar ratio of hydrochloric acid to potassium permanganate is 2:1), and finally wash with deionized water to obtain graphite oxide. Graphite oxide was reduced with 15 g of sodium borohydride aqueous solution at 80°C for 2 hours; after the reaction was completed, it was cooled to room temperature, centrifuged and washed, and vacuum-dried at 40°C for 2 hours to obtain a product of reduced graphene.

[0020] 0.01g of reduced graphene and 0.2g of aniline tetramer are ultrasonically dispersed in ace...

Embodiment 2

[0024] Mix 2.5g of natural graphite, 2.5g of sodium nitrate and 100ml of sulfuric acid, keep the ice bath at 0~5°C, slowly add 10g of potassium permanganate, stir continuously for 1 hour, add deionized water, heat to maintain the temperature at 100°C, Stir for 30 minutes, then add 100ml of ionized water and hydrogen peroxide, and add the hydrogen peroxide dropwise until the solution stops bubbling. Suction filter and wash with 640ml of 5% hydrochloric acid aqueous solution (the molar ratio of hydrochloric acid to potassium permanganate is 5:1), and finally wash with deionized water to obtain graphite oxide. Graphite oxide was reacted with 50 g of sodium borohydride aqueous solution at 100° C. for 24 hours; after the reaction was completed, it was cooled to room temperature, centrifuged and washed, and vacuum-dried at 100° C. for 24 hours to obtain reduced graphene.

[0025] 0.01g of reduced graphene and 0.005 aniline pentamer are ultrasonically dispersed in ethanol, and then a...

Embodiment 3

[0028] Mix 2.5g of natural graphite, 2.5g of sodium nitrate and 100ml of sulfuric acid, keep the ice bath at 0~5°C, slowly add 7.5g of potassium permanganate, stir continuously for 1 hour, add deionized water, and heat to maintain the temperature at 95°C , stirred for 20 minutes, then added 200ml of ionized water and hydrogen peroxide, and added the hydrogen peroxide dropwise until the solution stopped bubbling. Suction filter and wash with 320ml of 5% hydrochloric acid aqueous solution (the molar ratio of hydrochloric acid to potassium permanganate is 4:1), and finally wash with deionized water to obtain graphite oxide. Graphite oxide was reacted with 100ml of hydrazine hydrate at 90°C for 16h; after the reaction was completed, it was cooled to room temperature, centrifuged and washed, and vacuum-dried at 60°C for 16h to obtain a product of reduced graphene.

[0029]0.01g of reduced graphene and 0.15g of aniline hexamer were ultrasonically dispersed in tetrahydrofuran, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com