Prepn process of modified styrene-acrylic emulsion

A styrene-acrylic emulsion and modification technology, which is applied in the field of preparation of modified styrene-acrylic emulsion, can solve the problems of weather resistance, stain resistance and unsatisfactory coating effect, and achieve good compatibility and good adhesion of general additives , easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] name

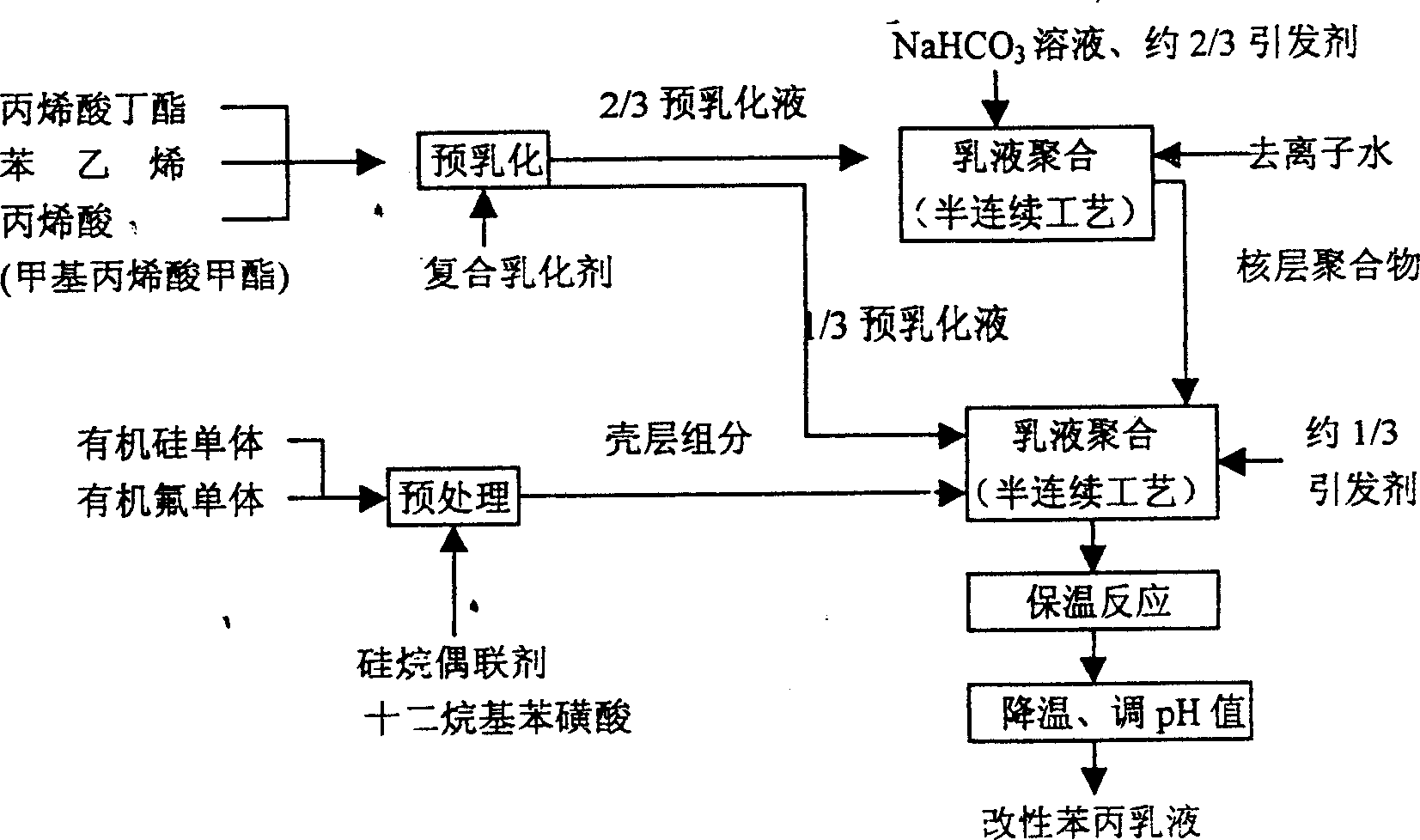

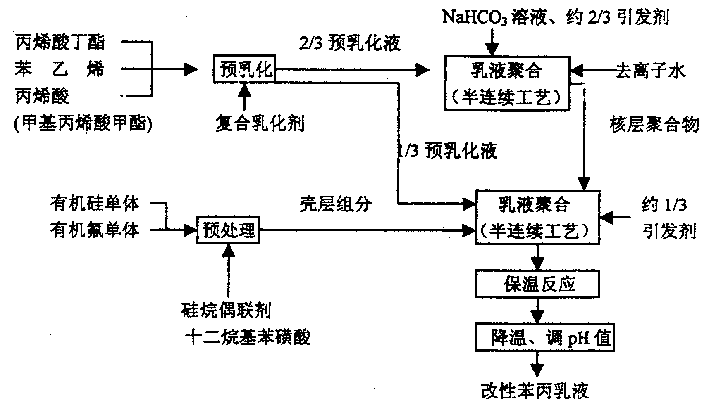

[0027] As shown in the process flow chart, first dissolve the emulsifier sodium dodecyl sulfate (SDS) in water, mix OP-10 and sodium dodecyl sulfate aqueous solution with styrene (St), butyl acrylate (BA), acrylic acid (AA) mixed and stirred vigorously for 0.5 hours to obtain a stable and uniform pre-emulsion A; ammonium persulfate (APS) was dissolved in water to form solution B; vinyltriethoxysilane (T) and octamethylcyclotetrasilane Oxane (D 4 ), Vinylcyclotetrasiloxane (D 4 V ), propylene trifluoroacetate (F 3), dodecylbenzenesulfonic acid were stirred and mixed at 45°C to obtain solution C, and sodium bicarbonate was dissolved in water to obtain solution D. Take 1 / 3 of each of pre-emulsion A and solution B, deionized water, and solution D into the reactor, stir to 74-80°C and react for about 0.5 hours, start to drop 2 / 3 of the remaining solution B, the remaining pre-emulsion 1 / 2 of liquid A, drop in about 3 hours (control pre-emulsion A to dro...

Embodiment 2

[0029] name

[0030] First, the emulsifier sodium dodecyl sulfate (SDS) was dissolved in water, and OP-10 and sodium dodecyl sulfate aqueous solution were mixed with styrene (St), methyl methacrylate (MMA) and butyl acrylate (BA ), acrylic acid (AA) were mixed and stirred vigorously for 0.5 hours to obtain stable and uniform pre-emulsions A1 and A2; ammonium persulfate (APS) was dissolved in water to form solution B; Methylcyclotetrasiloxane (D 4 ), Vinylcyclotetrasiloxane (D 4 V ), trifluoroacetylacrylamide (F A ), dodecylbenzenesulfonic acid was stirred and mixed at 45°C to obtain solution C, and sodium bicarbonate was dissolved in water to obtain solution D. Take 1 / 4 of pre-emulsion A1, 1 / 3 of pre-emulsion A2 and solution B1 / 3. Add deionized water and solution D into the reaction kettle, stir to 74°C and react for 0.5 hours, start to drop 1 / 3 of solution B, 1 / 4 of pre-emulsion A1, 1 / 3 of pre-emulsion A2, 3 The dripping is finished in about 1 hour (control the...

Embodiment 3

[0032] name

[0033] Dissolve the emulsifier sodium dodecyl sulfate (SDS) in water, mix OP-10 and sodium dodecyl sulfate aqueous solution with styrene (St) and butyl acrylate (BA), and stir vigorously for 0.5 hours to obtain a stable and uniform The pre-emulsion A; ammonium persulfate (APS) dissolved in water to make solution B; chloropropyltriethoxysilane (ClC 3 h 6 Si(OE) 3 ), octamethylcyclotetrasiloxane (D 4 ), Vinylcyclotetrasiloxane (D 4 V ), isofluoroacetyl acrylate (YF A ), dodecylbenzenesulfonic acid were stirred and mixed at about 45°C to obtain solution C, and sodium bicarbonate was dissolved in water to obtain solution D. Take 1 / 3 each of pre-emulsion A and solution B, deionized water, and solution D into a four-neck flask, stir until 74-80°C and react for about 0.5 hours, start to drop 2 / 3 of the remaining solution B, the remaining pre-emulsion Emulsion A, drop in about 3 hours (control pre-emulsion A to drop first). The temperature was raised to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com