Powder spray-coating sand pattern paint

A technology of sand pattern and powder, which is applied in the field of powder spraying sand pattern paint, can solve problems such as delamination, and achieve the effects of full paint film, high safety performance, and simple spraying and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

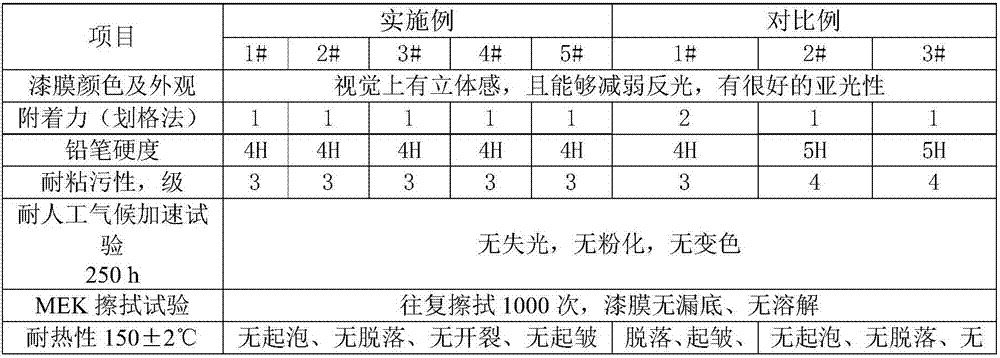

Examples

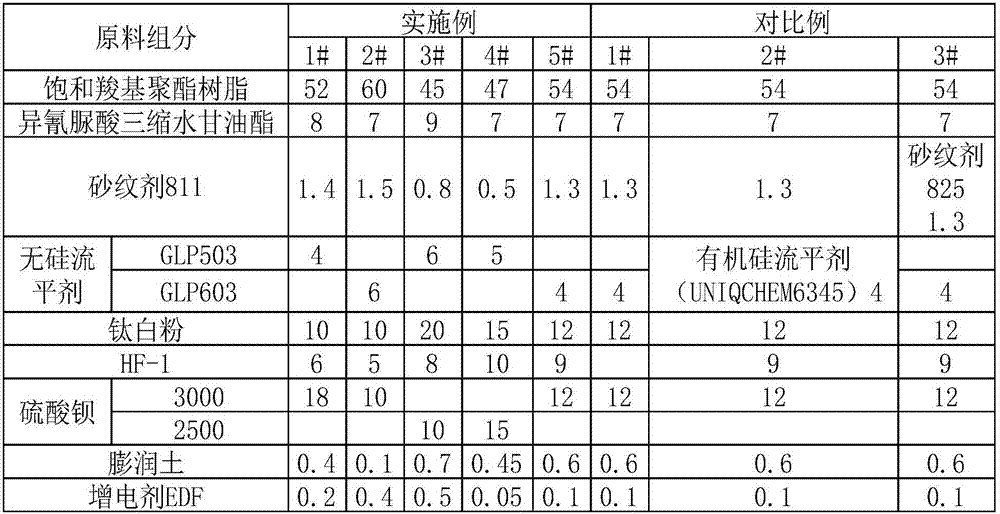

Embodiment 1

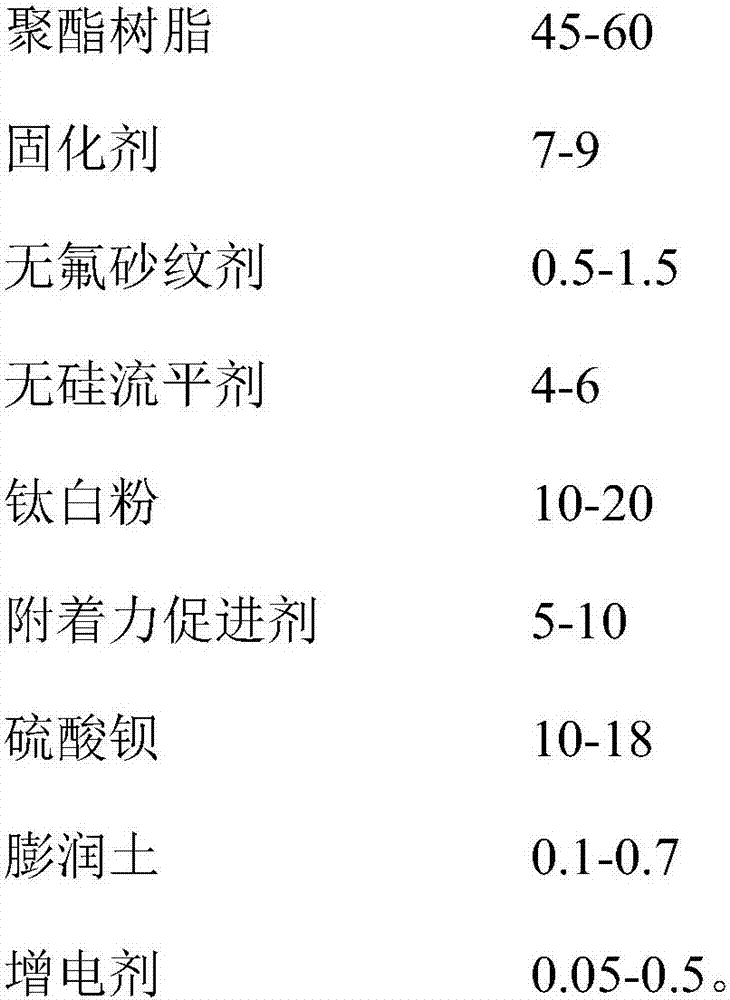

[0022] A kind of powder spray sand pattern paint, comprises following component according to weight fraction:

[0023] Saturated carboxyl polyester resin 52, triglycidyl isocyanurate 8, sand texture agent 811 1.4, GLP5034, titanium dioxide 10, HF-1 6, 3000 mesh barium sulfate 18, bentonite 0.4, and charge enhancer EDF0.2.

[0024] A preparation method for powder spraying sand pattern paint, comprising the steps of:

[0025] (1) Measure various raw materials according to the above formula ratio, and import them into the flip-type automatic mixer for mixing for 8-10 minutes;

[0026] (2) Use a twin-screw extruder to melt and extrude the mixed materials, and the extrusion temperature in each area of the screw is controlled at 100±4°C;

[0027] (3) Press the extruded material to a thin sheet with a thickness not greater than 1mm with a forming roller, and pulverize it with a crusher;

[0028] (4) grind the crushed material with a pulverizer;

[0029] (5) drying and passing th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com