Sun-shading fabric and preparation method thereof

A fabric and rectangle technology, applied in fabric surface trimming, fire-retardant and flame-retardant filament manufacturing, textile and other directions, can solve the problems of cumbersome technical process, weakened self-cleaning performance, etc., achieve good chemical stability, improve flexibility, and good toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

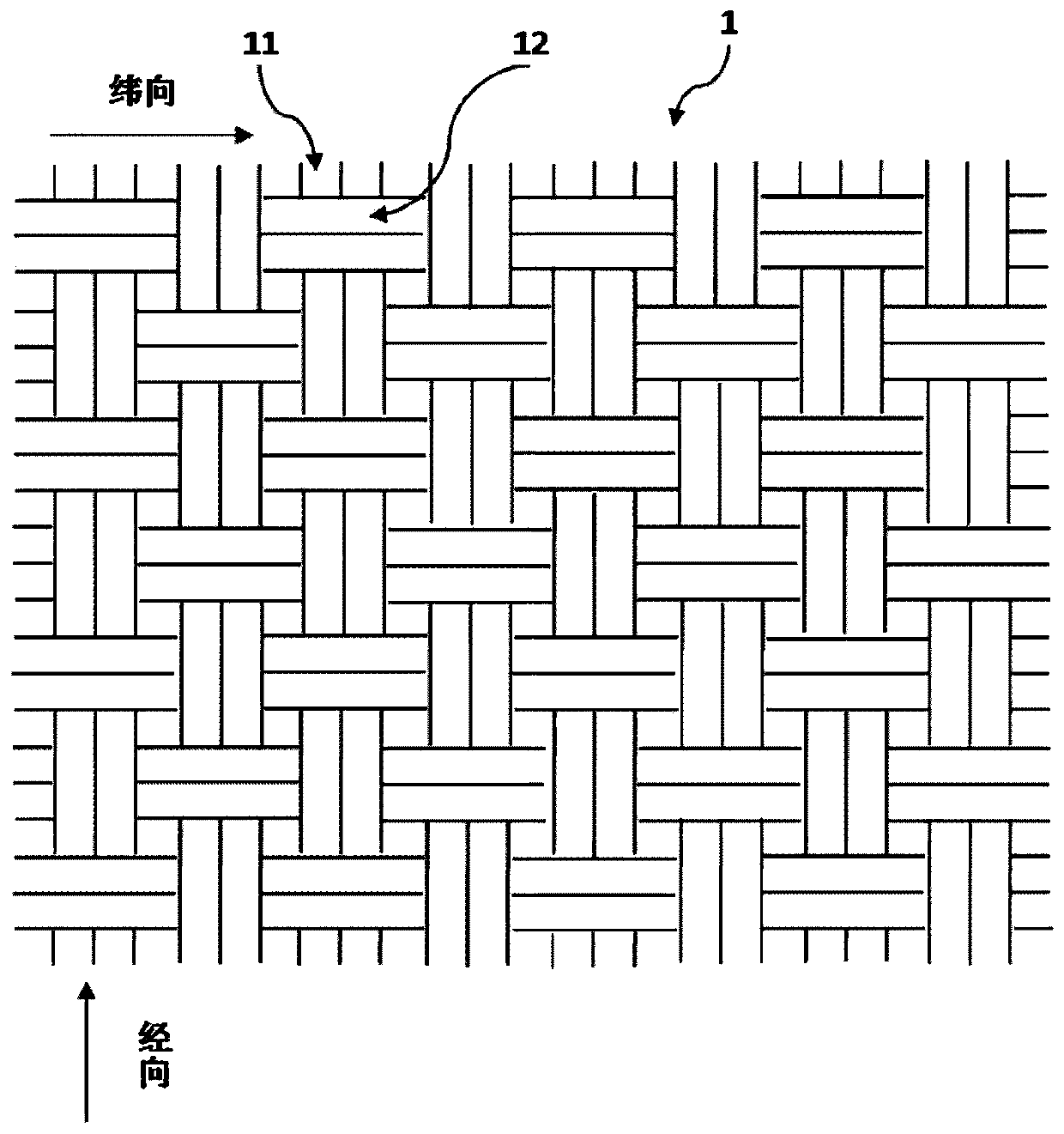

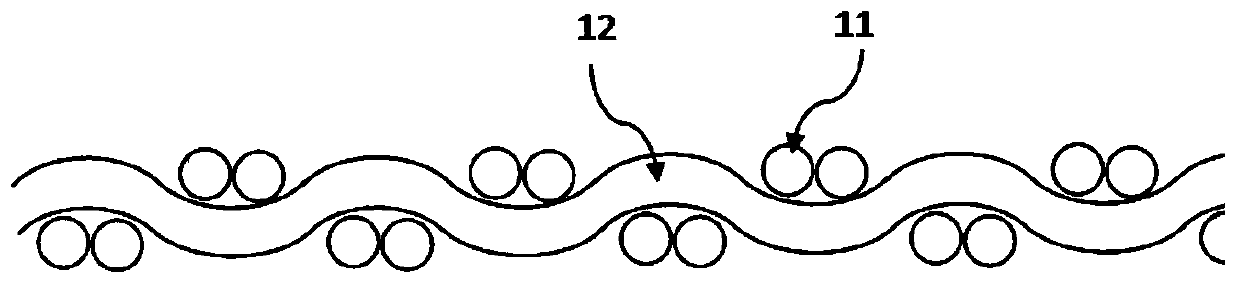

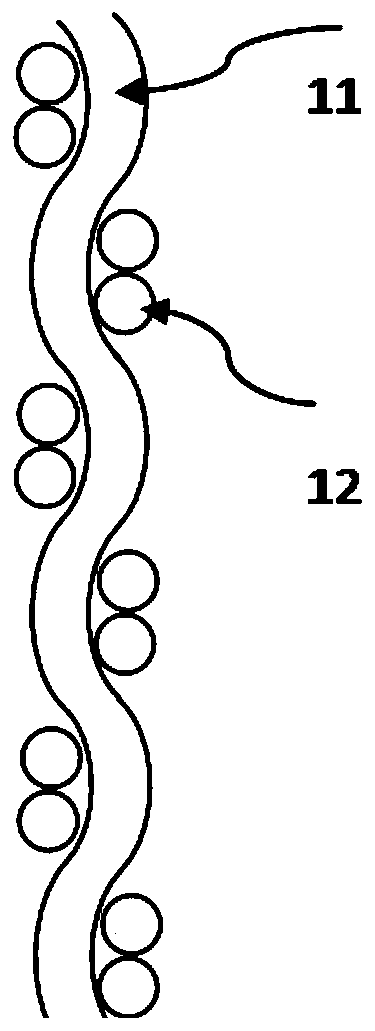

[0075] a kind of like Figure 1-3 The sunshade fabric shown includes fiber threads forming a double warp and double weft structure, including rectangular voids in the structure, and the fiber threads are made of halogen-free polyolefin composite materials through the following methods:

[0076] S1: Weigh raw materials by weight: 60 parts of linear low density polyethylene, 15 parts of ethylene-vinyl acetate copolymer, 20 parts of halogen-free flame retardant, 3 parts of expandable graphite, 3 parts of flame retardant synergist, 15 parts of flow modifier, 2 parts of polyvinylidene fluoride, 1 part of nano-titanium dioxide, 3 parts of compatibilizer, 1.5 parts of PE wax, 0.3 parts of 2-hydroxy-4-octyloxybenzophenone, hindered phenolic anti 0.3 parts of oxygen agent, 0.4 parts of toner, wherein the compatibilizer is maleic anhydride grafted high-density polyethylene, polymethyl methacrylate, γ-methacryloxy Propyltrimethoxysilane and ethylene-methyl acrylate copolymer, and the ma...

Embodiment 2

[0081] a kind of like Figure 1-3 The sunshade fabric shown includes fiber threads forming a double warp and double weft structure, including square voids in the structure, and the fiber threads are made of halogen-free polyolefin composite materials through the following methods:

[0082] S1: Weigh raw materials by weight: 60 parts of linear low density polyethylene, 15 parts of ethylene-vinyl acetate copolymer, 23 parts of halogen-free flame retardant, 4 parts of expandable graphite, 4 parts of flame retardant synergist, 17 parts of flow modifier, 2 parts of polyvinylidene fluoride, 1 part of nano-titanium dioxide, 4 parts of compatibilizer, 1.6 parts of PP wax, 0.3 parts of 2-hydroxy-4-octyloxybenzophenone, hindered phenolic anti 0.3 parts of oxygen agent, 0.4 parts of toner, wherein the compatibilizer is maleic anhydride grafted high-density polyethylene, polymethyl methacrylate, γ-methacryloxy Propyltrimethoxysilane and ethylene-methyl acrylate copolymer, and the maleic ...

Embodiment 3

[0087] The only difference from Example 1 is that the raw materials of Example 3 are: 60 parts of linear low density polyethylene, 15 parts of ethylene-vinyl acetate copolymer, 25 parts of halogen-free flame retardant, 4.5 parts of expandable graphite, flame retardant 4.5 parts of synergist, 17 parts of flow modifier, 2 parts of polyvinylidene fluoride, 1 part of nano-titanium dioxide, 4.5 parts of compatibilizer, 1.6 parts of PP wax, 0.3 parts of 2-hydroxy-4-octyloxybenzophenone 0.3 parts, 0.3 parts of hindered phenolic antioxidant, 0.4 parts of toner, wherein the compatibilizer is maleic anhydride grafted high-density polyethylene, polymethyl methacrylate, γ- Methacryloxypropyltrimethoxysilane and ethylene-methyl acrylate copolymer, and maleic anhydride grafted high-density polyethylene copolymer with a maleic anhydride graft rate of 3%, ethylene-vinyl acetate copolymer The content of vinyl acetate in the product is 25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com