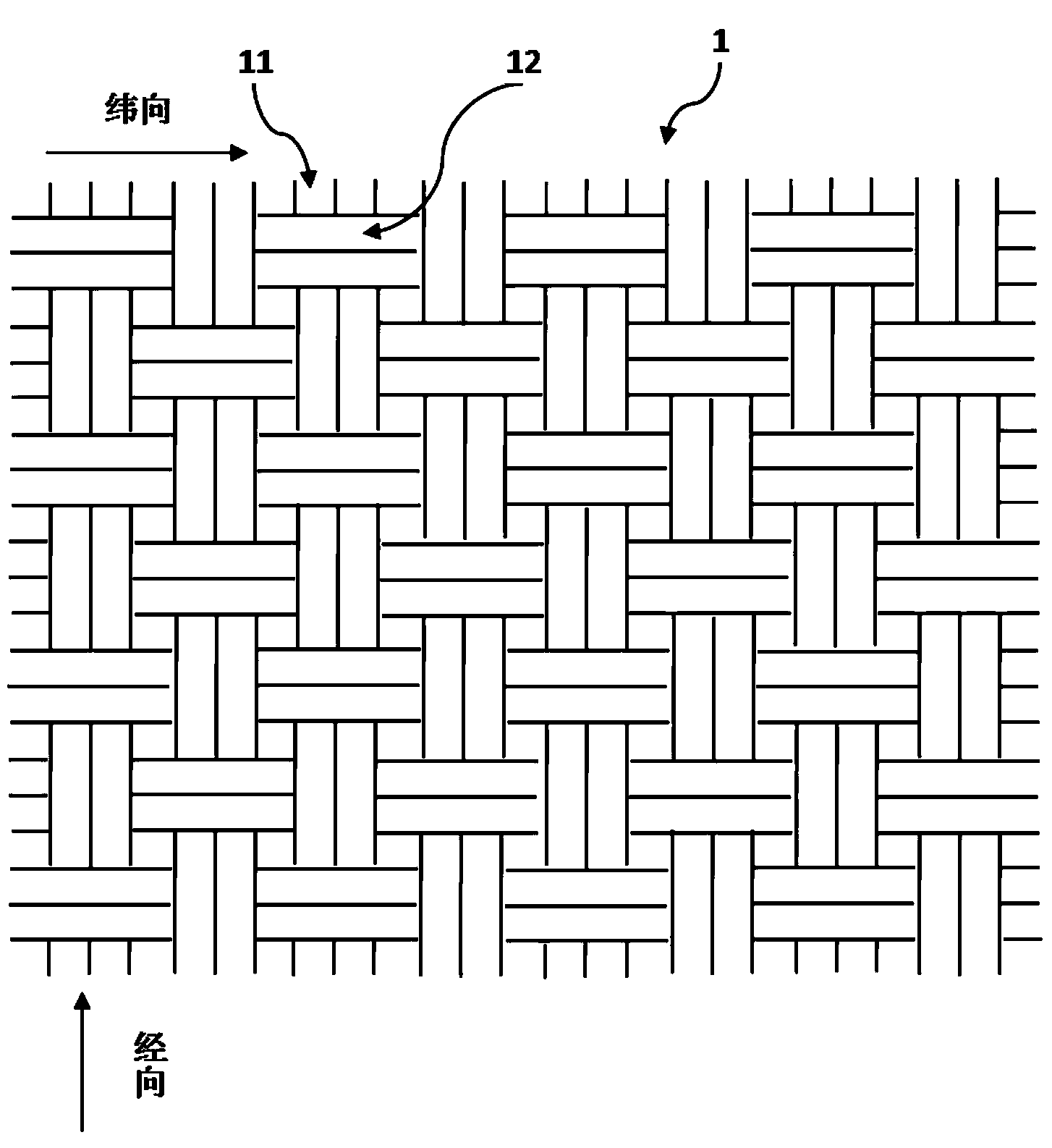

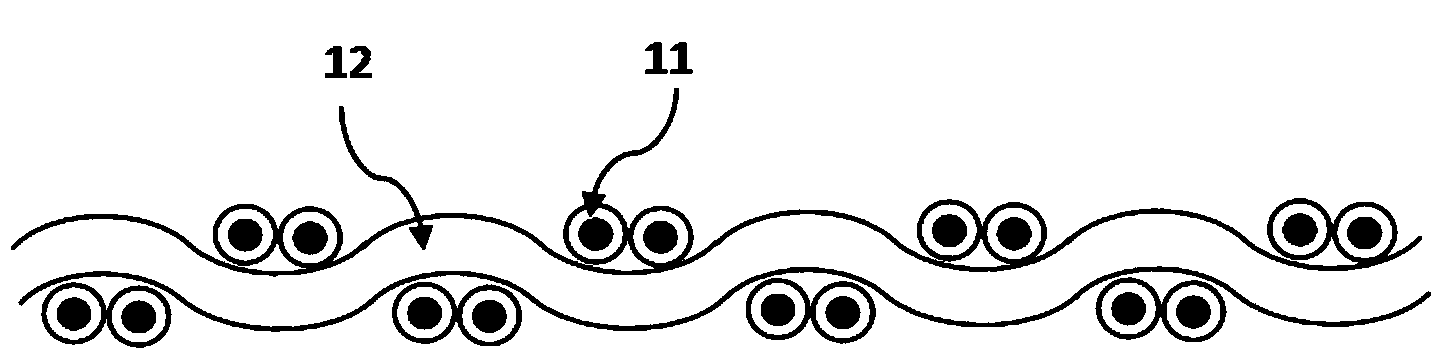

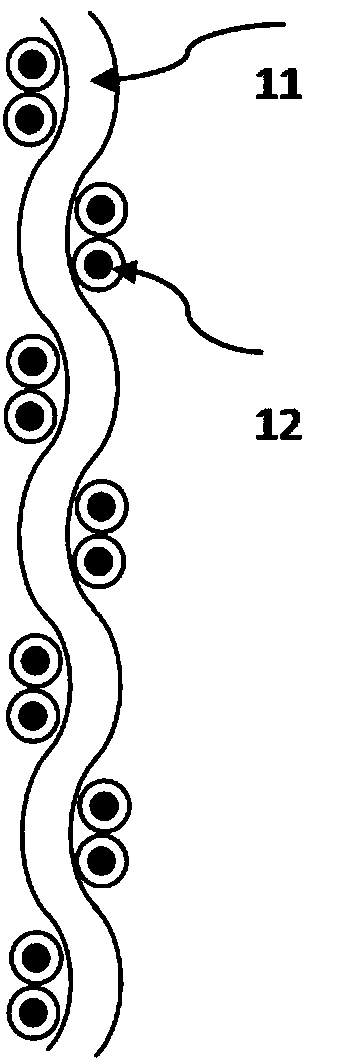

Halogen-free flame-retardant environment-friendly covered polyolefin yarn fabric and preparation method thereof

A technology of polyolefin and covered yarn, which is applied in the field of fabrics to achieve the effects of increased air permeability, improved flame retardancy, high heat resistance and barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Choose 220D polyester fiber.

[0064] According to the following parts by weight, the halogen-free flame-retardant environment-friendly polyolefin clad composite material is prepared:

[0065]HDPE: 50 parts

[0066] Ethylene-vinyl acetate copolymer: 8 parts

[0067] Halogen-free flame retardant: 20 parts

[0068] Zinc borate: 7 parts

[0069] Flame retardant synergist: 3 parts

[0070] Flow modifier: 10 parts

[0071] Compatibilizer: 3 parts

[0072] Lubricant: 1.5 parts

[0073] Anti-ultraviolet agent: 0.3 parts

[0074] Antioxidant: 0.3 parts

[0075] The compatibilizer is a maleic anhydride grafted high-density polyethylene copolymer, and the maleic anhydride grafting rate in the copolymer is 2%; the vinyl acetate content in the ethylene-vinyl acetate copolymer is 25%.

[0076] The above materials are mixed in a low mixer at 40-50°C for 5-10 minutes, and then put into a parallel co-rotating twin-screw machine for extrusion and granulation. The granulation te...

Embodiment 2

[0082] Choose 250D polyester fiber.

[0083] According to the following parts by weight, the halogen-free flame-retardant environment-friendly polyolefin clad composite material is prepared:

[0084] HDPE: 55 parts

[0085] Ethylene-vinyl acetate copolymer: 10 parts

[0086] Halogen-free flame retardant: 25 parts

[0087] Zinc borate: 6 parts

[0088] Flame retardant synergist: 3 parts

[0089] Flow modifier: 15 parts

[0090] Compatibilizer: 3 parts

[0091] Lubricant: 1.5 parts

[0092] Anti-ultraviolet agent: 0.3 parts

[0093] Antioxidant: 0.3 parts

[0094] The compatibilizer is a maleic anhydride grafted high-density polyethylene copolymer, and the maleic anhydride grafting rate in the copolymer is 2%; the vinyl acetate content in the ethylene-vinyl acetate copolymer is 30%.

[0095] According to the processing technology of Example 1, a halogen-free flame-retardant and environmentally friendly polyolefin covered yarn fabric was prepared, with the difference tha...

Embodiment 3

[0097] Choose 220D polyester fiber.

[0098] According to the following parts by weight, the halogen-free flame-retardant environment-friendly polyolefin clad composite material is prepared:

[0099] HDPE: 50 parts

[0100] Ethylene-vinyl acetate copolymer: 8 parts

[0101] Halogen-free flame retardant: 20 parts

[0102] Zinc borate: 7 parts

[0103] Flame retardant synergist: 5 parts

[0104] Flow modifier: 10 parts

[0105] Compatibilizer: 5 parts

[0106] Lubricant: 1.5 parts

[0107] Anti-ultraviolet agent: 0.3 parts

[0108] Antioxidant: 0.3 parts

[0109] The compatibilizer is ethylene-vinyl acetate copolymer grafted with maleic anhydride, and the grafting rate of maleic anhydride in the copolymer is 1.5%; the content of vinyl acetate in the ethylene-vinyl acetate copolymer is 25%.

[0110] Subsequent fabric preparation process is the same as in Example 1. The main physical properties of the obtained halogen-free flame-retardant and environmentally friendly pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com