Soil conditioner with bamboo charcoal and method for preparing soil conditioner

A soil conditioner and bamboo charcoal technology, applied in the field of agricultural chemical industry, can solve the problems of poor improvement effect, short duration, large dosage, etc., and achieve the effects of improving soil permeability and water retention, improving effectiveness, and promoting growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The formula of this embodiment:

[0054] Bamboo charcoal powder: 50%

[0055] Humic acid: 15%

[0056] Quicklime powder: 20%

[0057] Diatomaceous earth: 5%

[0058] Urea: 8%

[0059] Iron EDTA: 2%

[0060] crafting process:

[0061] (1) Crush and cut 500kg alpine bamboo or bamboo waste, and dry it naturally or artificially for later use.

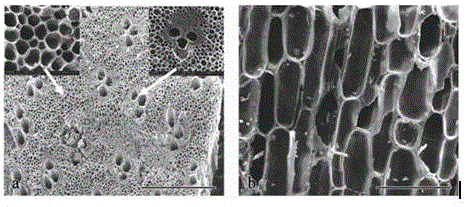

[0062] (2) Pyrolysis and carbonization of the scrap obtained in step (1) at 450°C for 2 hours under anaerobic conditions, after cooling, pulverize through a pulverizer and pass through a 100-mesh sieve, and dry. The microstructure of the obtained bamboo charcoal powder is as follows: figure 1As shown, it can be seen that bamboo charcoal has special pores composed of onion-like fullerenes (C60) and expanded carbon nanotubes;

[0063] (3) Pass humic acid through a 100-mesh sieve and dry;

[0064] (4) Crushing quicklime, passing through a 100-mesh sieve, and drying;

[0065] (5) Pass diatomaceous earth through a 100-mesh sieve ...

Embodiment 2

[0070] Bamboo charcoal powder: 45%

[0071] Fulvic acid: 16%

[0072] Quicklime powder: 17%

[0073] Diatomaceous earth: 8%

[0074] Urea: 7%

[0075] Clay: 5.5%

[0076] Iron EDTA: 1.5%

[0077] crafting process:

[0078] (1) Crush and cut 500kg alpine bamboo or bamboo waste, and dry it naturally or artificially for later use;

[0079] (2) Pyrolysis and carbonization of the crushed material obtained in step (1) at 450°C for 2 hours under anaerobic conditions, after cooling, crush through a pulverizer through an 80-mesh sieve, and dry;

[0080] (3) Pass fulvic acid through an 80-mesh sieve and dry;

[0081] (4) Pulverize the quicklime, pass through an 80-mesh sieve, and dry;

[0082] (5) Pass diatomaceous earth through an 80-mesh sieve and dry;

[0083] (6) Urea is pulverized, passed through an 80-mesh sieve, and dried;

[0084] (7) EDTA iron is passed through a 80-mesh sieve and dried;

[0085] (8) Measure the above-mentioned bamboo charcoal powder, quicklime powde...

Embodiment 3

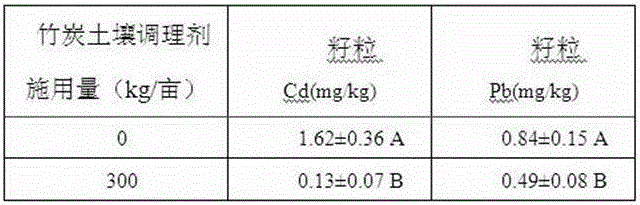

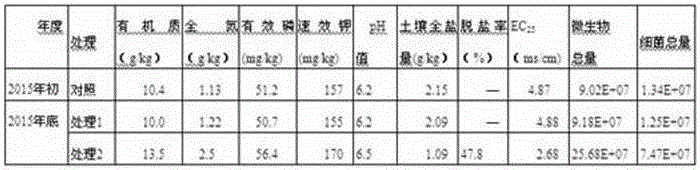

[0087] The sample developed in Example 1 was used as a field demonstration test in Lvfang Village, Miaoqian Town, Liancheng County, Longyan City, Fujian Province. See the results below:

[0088] 1. Test location

[0089] Lufang Village, Miaoqian Town, Liancheng County, Longyan City, Fujian Province (N25°21.392′, E116°42.469′)

[0090] 2. Test time: April 2015 ~ October 2015

[0091] 3. Soil for test:

[0092] The Cd content of the paddy field tested was 4.0mg / kg, the Pb content was 625mg / kg, and the soil pH was 6.32

[0093] 4. Test crop: middle rice (Fengyou 559)

[0094] 5. Test treatment:

[0095] Control: conventional fertilization

[0096] Treatment: bamboo charcoal soil conditioner 300kg / mu

[0097] 6. Test process:

[0098] Sprinkle the bamboo charcoal soil conditioner on the soil surface before watering, and mix it with a 15cm rotary tiller and a harrow. Then transplant the seedlings, apply 45 kg / mu of ammonium bicarbonate, 8.9 kg / mu of urea, 15 kg / mu of super...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com