UV (Ultraviolet) curable coating as well as preparation method and application thereof

A curing coating, polyurethane acrylic technology, applied in the field of coatings, can solve the problems of high hardness, easy to break when bending, achieve low odor, less environmental hazards, improve flexibility and bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

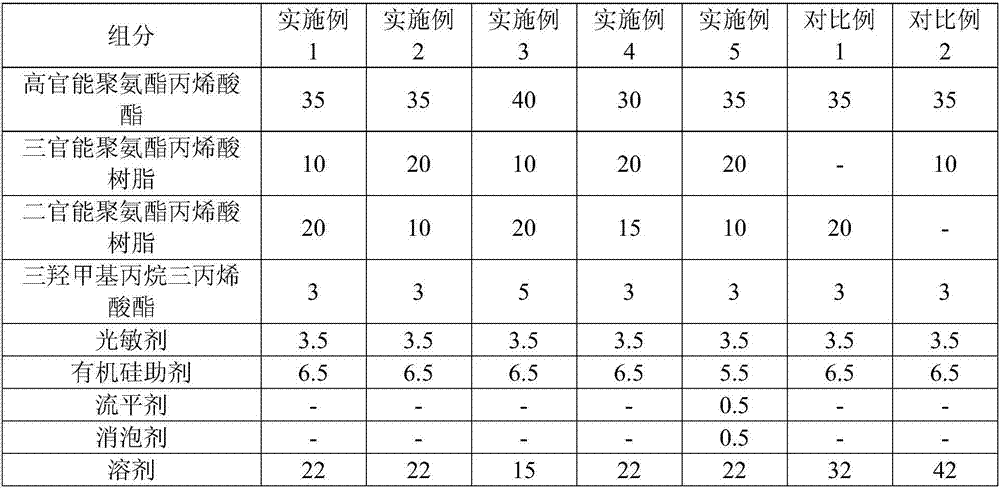

Examples

Embodiment 1

[0039]A kind of UV curable coating, it is made up of following components according to weight percentage:

[0040] High functional urethane acrylate 35%; Trifunctional urethane acrylate resin 10%; Difunctional urethane acrylate resin 20%; Trimethylolpropane triacrylate 3%; Photosensitizer 3.5%; Silicone additive 6.5%; Solvent 22% .

[0041] The TG point of the high-functional polyurethane acrylate is 69, the molecular weight is 1000, the viscosity is 2000mpa.s / 60°C, and the elongation is 2%; the viscosity of the trifunctional polyurethane acrylate resin is 4500mpa.s / 60°C, The ratio is 37%; the viscosity of the difunctional polyurethane acrylic resin is 9000mpa.s / 60°C, and the molecular weight is 1000; the acid value (KOH / g) of the trimethylolpropane triacrylate is 0.2mg, and the refractive index is 1.47 nD, the surface tension is 35dyne / cm; the photosensitizer is 1-hydroxy-cyclohexylbenzophenone.

[0042] The above-mentioned components are added into the container according ...

Embodiment 2

[0044] A kind of UV curable coating, it is made up of following components according to weight percentage:

[0045] High functional urethane acrylate 35%; Trifunctional urethane acrylate resin 20%; Difunctional urethane acrylate resin 10%; Trimethylolpropane triacrylate 3%; Photosensitizer 3.5%; Silicone additive 6.5%; Solvent 22% .

[0046] The concrete selection of each component is with embodiment 1.

[0047] The above-mentioned components are added into the container according to the weight percentage, and mixed uniformly under the condition of stirring to obtain the UV curable coating.

Embodiment 3

[0049] A kind of UV curable coating, it is made up of following components according to weight percentage:

[0050] High functional urethane acrylate 40%; trifunctional urethane acrylic resin 10%; difunctional urethane acrylic resin 20%; trimethylolpropane triacrylate 5%; photosensitizer 3.5%; silicone additive 6.5%; solvent 15% .

[0051] The concrete selection of each component is with embodiment 1.

[0052] The above-mentioned components are added into the container according to the weight percentage, and mixed uniformly under the condition of stirring to obtain the UV curable coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com