Water-based sand-textured paintand preparation method thereof

A sandy, water-based technology, applied in the field of water-based sandy paint and its preparation, can solve the problems of rework repair, water-based sandy paint's first pass rate of finished products is difficult to reach 100%, and achieve simple spraying and use and fast film forming time , high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

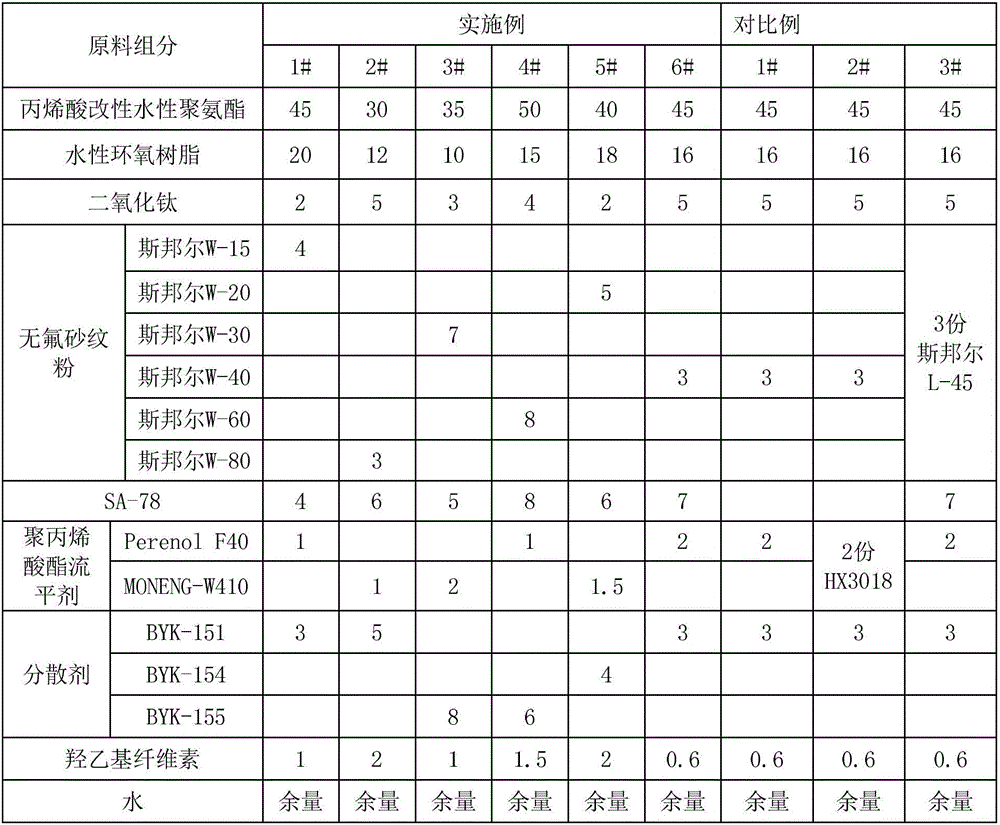

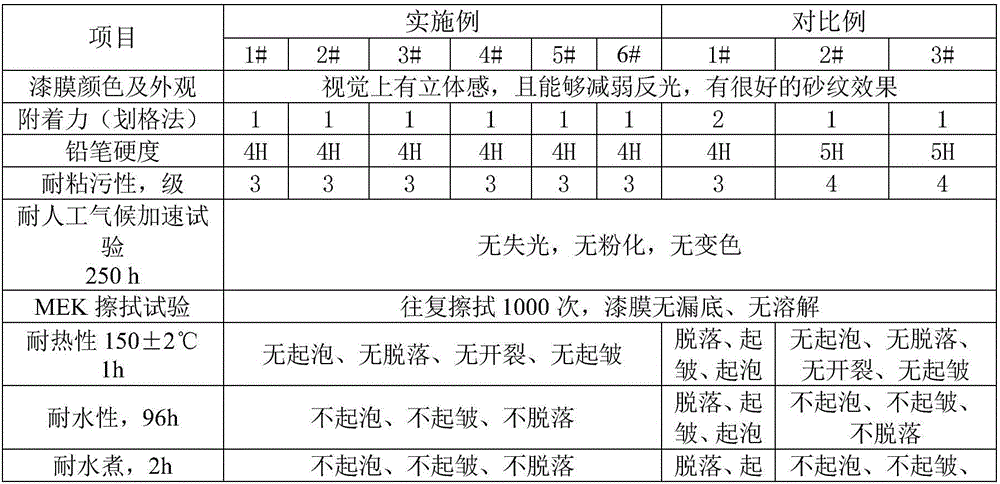

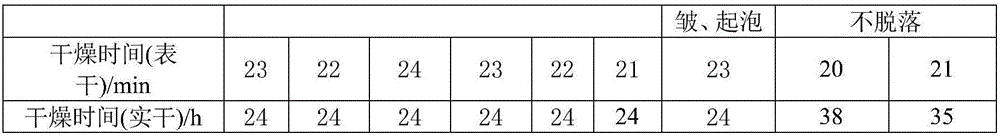

Examples

Embodiment 1

[0037] A kind of water-based sand pattern paint comprises following components according to weight fraction:

[0038] Acrylic modified waterborne polyurethane 45

[0039] Waterborne epoxy resin 20

[0040] Pigment titanium dioxide 2

[0041] Fluorine-free sanding powder Spanger W-15, 4

[0042] Polyacrylate leveling agent Perenol F40, 1

[0043] Adhesion Promoter A-78, 4

[0044] Dispersant BYK-151, 3

[0045] Thickener Hydroxyethyl Cellulose 1

[0046] water balance.

[0047] A preparation method of water-based sand grain paint, comprising the steps of:

[0048] (1) Add acrylic-modified water-based polyurethane, water-based epoxy resin, dispersant, polyacrylate leveling agent, and part of water into the stirring tank in sequence, and stir for 10-20min at a speed of 600-800r / min;

[0049] (2) Add fluorine-free sand grain powder and pigments, and stir and disperse for 20-30min at a speed of 1000-1200r / min;

[0050] (3) Add the adhesion promoter and the remaining water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com