Water-based matt scratch-resistant soft synthetic leather

A synthetic leather and matte technology, applied in the fields of water-based matte, soft synthetic leather, and scratch resistance, can solve the problems of poor wear resistance, soft hand feel, easy yellowing, etc., and achieves fine texture and excellent coating. , The effect of pure water and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

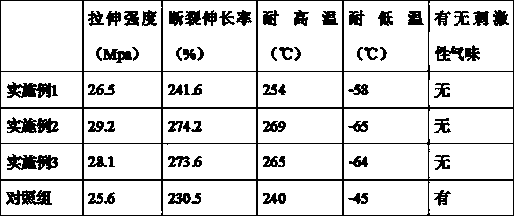

Examples

Embodiment 1

[0034] A water-based matte, scratch-resistant, soft synthetic leather is characterized in that it includes:

[0035] Base fabric layer, wet-process polyurethane coating on base fabric, dry-process polyurethane layer on wet-process polyurethane layer, high-solids printing on pearlescent layer on dry-process polyurethane layer, stencil coating on pearlescent layer The matte treatment layer, the water-based matte treatment layer coated on the matte treatment layer.

[0036] Production of wet-process polyurethane layer:

[0037] a: Add 60 parts of dimethylformamide, 0.06 parts of defoamer, 0.2 parts of anionic coagulation regulator, 0.2 parts of nonionic coagulation regulator, 0.1 part of water-based color paste to the container, and use 35- Stir at a speed of 45 rev / min for 5-10min to prepare mixture B for subsequent use;

[0038] b: Add 30 parts of light calcium, 15 parts of white wood fiber powder, and 100 parts of polyurethane resin to mixture B, stir at a speed of 35-45 rpm...

Embodiment 2

[0053] A water-based matte, scratch-resistant, soft synthetic leather is characterized in that it includes:

[0054] Base fabric layer, wet-process polyurethane coating on base fabric, dry-process polyurethane layer on wet-process polyurethane layer, high-solids printing on pearlescent layer on dry-process polyurethane layer, stencil coating on pearlescent layer The matte treatment layer, the water-based matte treatment layer coated on the matte treatment layer.

[0055] Production of wet-process polyurethane layer:

[0056]a: Add 70 parts of dimethylformamide, 0.07 parts of defoamer, 0.25 parts of anionic coagulation regulator, 0.22 parts of nonionic coagulation regulator, 0.3 parts of water-based color paste into the container, and use 35- Stir at a speed of 45 rev / min for 5-10min to prepare mixture B for subsequent use;

[0057] b: Add 32 parts of light calcium, 20 parts of white wood fiber powder, and 100 parts of polyurethane resin to mixture B, stir at a speed of 35-45...

Embodiment 3

[0070] A water-based matte, scratch-resistant, soft synthetic leather is characterized in that it includes:

[0071] Base fabric layer, wet-process polyurethane coating on base fabric, dry-process polyurethane layer on wet-process polyurethane layer, high-solids printing on pearlescent layer on dry-process polyurethane layer, stencil coating on pearlescent layer The matte treatment layer, the water-based matte treatment layer coated on the matte treatment layer.

[0072] Production of wet-process polyurethane layer:

[0073] a: Add 75 parts of dimethylformamide, 0.08 parts of defoamer, 0.3 parts of anionic coagulation regulator, 0.25 parts of nonionic coagulation regulator, 0.5 parts of water-based color paste into the container, and use 35- Stir at a speed of 45 rev / min for 5-10min to prepare mixture B for subsequent use;

[0074] b: Add 35 parts of light calcium, 25 parts of white wood fiber powder, and 100 parts of polyurethane resin to mixture B, stir at a speed of 35-45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com