Multi-functional glutinous rice plant liquid coating

A plant-based, multi-functional technology, applied in the field of coatings, can solve problems such as human harm, difficulty in meeting electronic information technology requirements, and use restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] First, add quicklime into water and stir for 30 minutes. After clarification, the upper solution is taken as lime slurry clear liquid, which is set aside.

[0024] Next, mix 10 parts of wild chrysanthemum, 10 parts of orange peel, and 20 parts of citrus leaves into 100 parts of water at 60° C. for 1 hour, and after natural cooling, take the clear solution as a plant extract and set it aside.

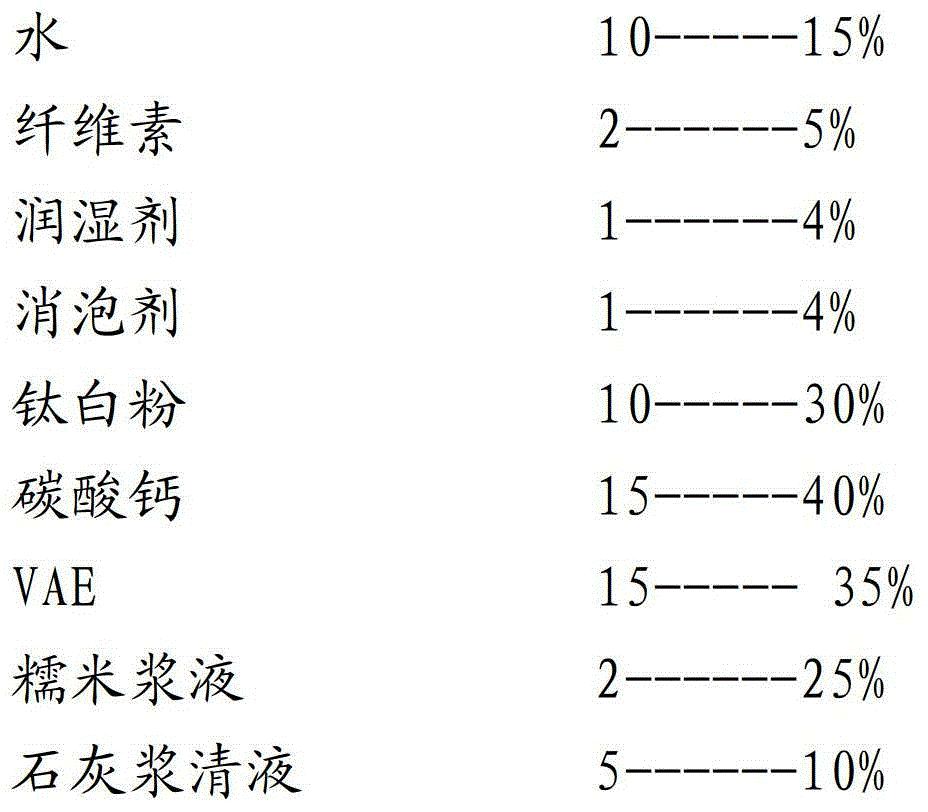

[0025] Again, follow the recipe below (in parts by mass) with the following steps:

[0026]

[0027] ①Add hydroxypropyl methylcellulose into water and stir for 30 minutes;

[0028] ②Add polycarboxylate sodium salt dispersant in turn, and stir for 30 minutes with silicone defoamer;

[0029] ③ Add titanium dioxide, superfine calcium carbonate is strongly dispersed for 30 minutes;

[0030] ④Add polyvinyl acetate-ethylene emulsion, and stir the glutinous rice slurry for 20 minutes;

[0031] ⑤Add lime slurry and stir for 20 minutes;

[0032] ⑥ Add plant extract, nano silver, and...

Embodiment 2

[0042] First, add quicklime into water and stir for 30 minutes. After clarification, the upper solution is taken as lime slurry clear liquid, which is set aside.

[0043] Next, mix 10 parts of wild chrysanthemum, 10 parts of orange peel, and 20 parts of citrus leaves into 100 parts of water at 60° C. for 1 hour, and after natural cooling, take the clear solution as a plant extract and set it aside.

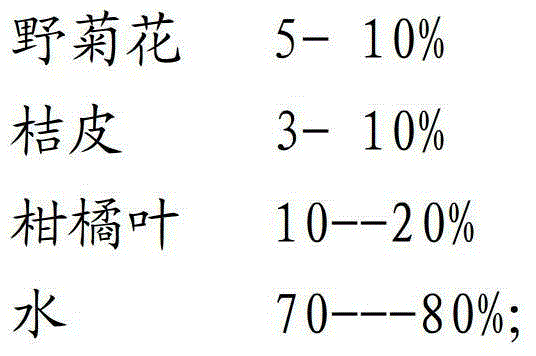

[0044] Again, follow the recipe below (in parts by mass) with the following steps:

[0045]

[0046] Adopt this formula, produce the coating of 10 batches according to the production method of embodiment one, and its main technical indicators are all in the following table scope:

[0047] pH

Embodiment 3

[0049] First, add quicklime into water and stir for 30 minutes. After clarification, the upper solution is taken as lime slurry clear liquid, which is set aside.

[0050] Next, mix 10 parts of wild chrysanthemum, 10 parts of orange peel, and 20 parts of citrus leaves into 100 parts of water at 60° C. for 1 hour, and after natural cooling, take the clear solution as a plant extract and set it aside.

[0051] Again, follow the recipe below (in parts by mass) with the following steps:

[0052]

[0053] Adopt this formula, produce the coating of 10 batches according to the production method of embodiment one, and its main technical indicators are all in the following table scope:

[0054] pH

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com