[0002] With the rapid development of fast food items, it is convenient for people to eat easily. The amount of instant noodles (instant noodles) is increasing, and instant noodles are packaged with

plastic film. Regarding food packaged with

plastic film, there are biscuits, candies, noodles, The used

plastic packaging bags, snacks, etc., because the inner surface of these plastic films must be printed with words and patterns such as product names,

trademark brands, product sources, ingredients, etc., and the colors are bright, especially the golden patterns are not included in traditional inks.

Copper or

zinc accounts for 60-80% and also contains other

heavy metals, seriously polluting the environment

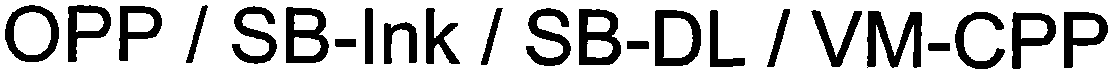

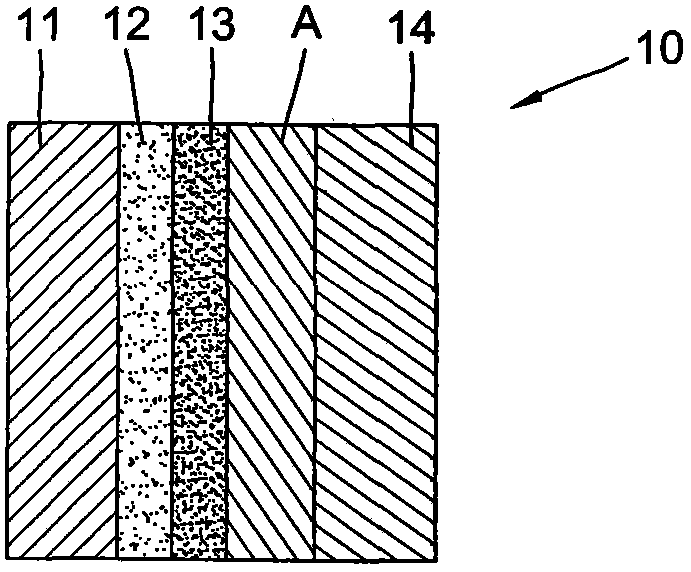

like figure 1 As shown, the

plastic film mainly contains an outer layer of OPP

polypropylene (Orient

polypropylene extended by alignment), and the pattern is printed on the inner surface of the OPP

polypropylene layer. The printing is printed with

organic solvent-based ink (

Solvent Base Ink) On the inner surface of the OPP polypropylene layer, an

organic solvent-based adhesive (

Solvent Base Dry Lami nation) is used to adhere an inner layer of VM-CPP polypropylene [Vacuum Metalized-Cast polypropylene

vacuum evaporation aluminum plating, non-alignment extension (extensible)

Polypropylene], although there is an outer layer of OPP polypropylene and an inner layer of VM-CPP as isolation

organic solvent ink SB-Ink and organic solvent adhesive SB-DL, but after a long time, the organic solvent ink SB-Ink And organic solvent-based adhesive SB-DL internal poisons will volatilize and affect the

human body;

[0003] As shown in Appendix 2, it is the test of the above-mentioned packaging materials by the Institute of

Food Industry Development. The special

gas transmission rate is 13.79, and the gas in this test is

toluene; these organic solvent-based inks SB-Ink and / or organic solvent-based adhesives The hazards of SB-DL to

human health are becoming more and more obvious, and people may become victims of ink

pollution. The most important pollutants (inks, adhesives) in printing OPP polypropylene often use

ethanol, isopropanol, and butyl

alcohol.

Alcohol,

propanol, methyl ethyl

ketone,

ethyl acetate,

butyl acetate,

toluene,

xylene and other organic solvents, although these organic solvents are used in dry lamination, but the above-mentioned pollutants will remain and cause harm to the

human body. If it is a printed plastic film with a large printing area and a thick ink layer, there will be more residual solvents, and the toxic substances released during use will pollute the air and endanger people's health. The

diluent containing

toluene is toxic. It has a strong pungent smell. After infiltrating into food, it is reported that long-term consumption will cause

cancer and affect the

central nervous system of the brain, causing great harm to

human health;

[0004] At present, the gravure printing ink in the plastic film of Caiyi packaging in Taiwan, China is generally made of chlorinated polymers and contains a large amount of organic solvents (accounting for about 50%). Among them, solvents such as toluene,

ethyl acetate, and

butanone have low boiling points and high volatility. Aromatic hydrocarbons are both toxic and flammable, and traditional inks have been used in the color art industry for a long time. With the development of information and customers' requirements for aesthetics, large areas of golden patterns are often designed on art patterns, and these patterns The main components of the golden ink that must be used are

heavy metals such as

copper or

zinc (as shown in Annex 3). These organic solvents and heavy metals are not only easy to remain on the packaging materials, but also are discharged into the environment due to the uncontrollable

pollution of the process, causing air, Water and soil pollution, and once farmland soil is polluted by heavy metals will seriously endanger the growth of crops, excessive heavy metals will be absorbed by crops and accumulate in plants, and crops containing heavy metals will affect the safety of

human food through the

food chain. In terms of the historical background of heavy

metal pollution in rivers and rivers in Taiwan, in 1990, the

Environmental Protection Agency monitored the case of Erren River in the south. At that time, regardless of its downstream or tributaries, the river itself and its

sediment were seriously polluted by heavy metals. Among them,

copper, zinc and lead are the main pollution sources, and their content is 20-40 times higher than that in unpolluted areas. These heavy metals may enter the

food chain directly or indirectly, causing human beings and other organisms to absorb and accumulate to cause

toxicity. , which is called biomagnification

Login to View More

Login to View More  Login to View More

Login to View More