Leather pattern color forming process for engraving plate

A forming process and leather technology, applied in the field of decorative materials, can solve the problems of uneven quality, difficulty in large-scale production, and no hand feeling on the surface, and achieve the effect of meeting large-scale mass production, improving production capacity, and not easy to fade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

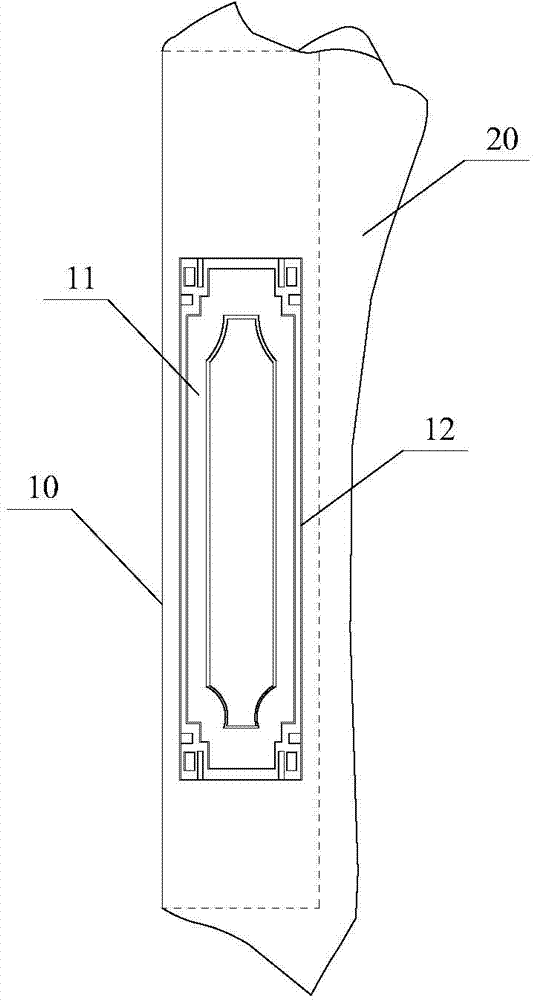

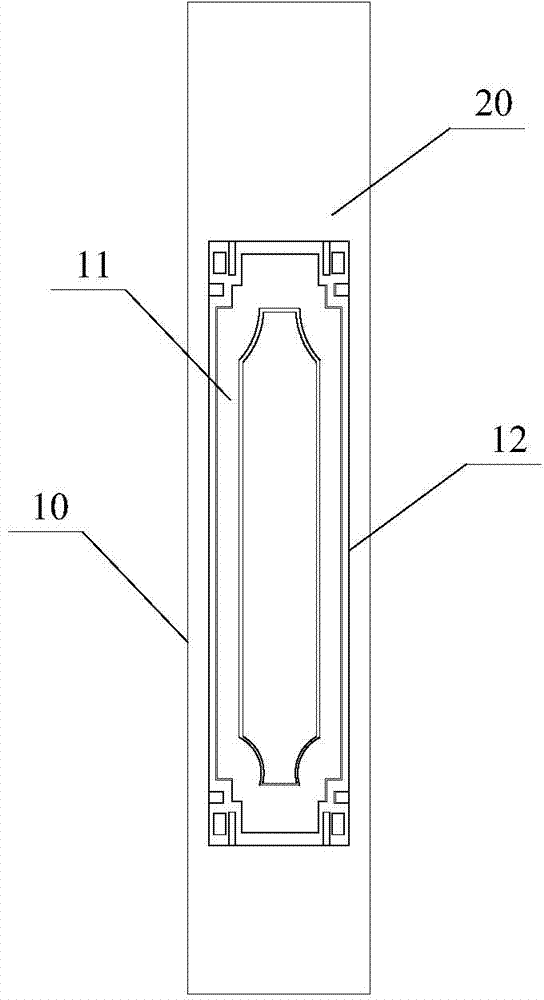

[0017] Such as figure 1 , figure 2 As shown, the present invention provides a kind of engraving plate with pattern color, comprises engraving plate 10 and the leather 20 that becomes, and engraving pattern 11 is arranged on the front of engraving plate 10, and customer selects engraving pattern 11 of different shapes according to one's own preference , the engraving pattern 11 all has the pit 12 that produces in the engraving process at each engraving place, and leather 20 is artificial leather, comprises PVC layer and covers the PU layer on the outside of described PVC layer, and traditional leather adopts in the manufacturing process The cloth bottom is made of re-injection-molded PVC material. This kind of leather is not resistant to hydrolysis due to the air holes in the cloth bottom, and it is easy to leak air when blistering, so it is impossible to blister th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com