Method for making water-based matte scratch-resistant and flexible synthetic leather

A production method and technology for synthetic leather, applied in textiles and papermaking, etc., can solve the problems of soft hand feel, poor flexibility, and poor elasticity, and achieve the effects of high coating film fullness, good flexibility, and soft hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

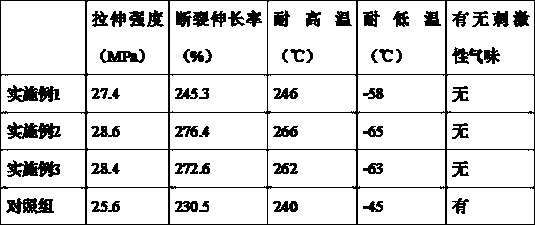

Examples

Embodiment 1

[0026] A method for making water-based matte, scratch-resistant, and soft synthetic leather, characterized in that the specific steps are as follows:

[0027] Step 1: The production of Bass: first prepare the wet-process polyurethane coating, then clean the base cloth, iron it once, dry it once, then vacuum defoam the wet-process polyurethane coating, and then apply the wet-process polyurethane coating Put it on the base cloth, then enter the coagulation tank for coagulation, then wash with water, squeeze dry, fix the width, iron it for the second time, dry it for the second time, cool it, and wind it up to make the bass.

[0028] Step 2: Preparation of water-based matte surface treatment agent: 100 parts of water-based PU resin, 50 parts of deionized water, and 1 part of water-based plasticizer are stirred at a speed of 800-1000 rpm for 5-10 minutes to prepare Add 1 part of curing agent to the mixed liquid A and stir evenly at a speed of 800-1000 rpm to obtain a water-based t...

Embodiment 2

[0032] A method for making water-based matte, scratch-resistant, and soft synthetic leather, characterized in that the specific steps are as follows:

[0033] Step 1: The production of Bass: first prepare the wet-process polyurethane coating, then clean the base cloth, iron it once, dry it once, then vacuum defoam the wet-process polyurethane coating, and then apply the wet-process polyurethane coating Put it on the base cloth, then enter the coagulation tank for coagulation, then wash with water, squeeze dry, fix the width, iron it for the second time, dry it for the second time, cool it, and wind it up to make the bass.

[0034] Step 2: Production of water-based matte surface treatment agent: 100 parts of water-based PU resin, 70 parts of deionized water, and 3 parts of water-based plasticizer are stirred at a speed of 800-1000 rpm for 5-10 minutes to prepare Add 1.5 parts of curing agent to the mixed solution A and stir evenly at a speed of 800-1000 rpm to obtain a water-ba...

Embodiment 3

[0038] A method for making water-based matte, scratch-resistant, and soft synthetic leather, characterized in that the specific steps are as follows:

[0039] Step 1: The production of Bass: first prepare the wet-process polyurethane coating, then clean the base cloth, iron it once, dry it once, then vacuum defoam the wet-process polyurethane coating, and then apply the wet-process polyurethane coating Put it on the base cloth, then enter the coagulation tank for coagulation, then wash with water, squeeze dry, fix the width, iron it for the second time, dry it for the second time, cool it, and wind it up to make the bass.

[0040] Step 2: Preparation of water-based matte surface treatment agent: 100 parts of water-based PU resin, 90 parts of deionized water, and 5 parts of water-based plasticizer are stirred at a speed of 800-1000 rpm for 5-10 minutes to prepare Mixed solution A, add 2 parts of curing agent and stir evenly at a speed of 800-1000 rpm to prepare a water-based tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com