Flame-retardant thermoplastic resin composition

A thermoplastic resin and composition technology, applied in the field of electric wires and cables, as well as molded parts, and power cords, can solve the problems of reduced compatibility, reduced crystallinity, reduced rigidity, etc., and achieves excellent discoloration resistance and low smoke generation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Hereinafter, the present invention will be described in more detail by way of examples, but the present invention is not limited to the following examples unless the gist is exceeded. The raw materials and evaluation methods used in the following examples are as follows.

[0054]

[0055] (polyethylene resin):

[0056] (a1) Ethylene-α-olefin copolymer [density 0.898g / cm 3 , ethylene-1-hexene copolymer, "kernel (カ—ネル) KF360" manufactured by Nippon Polyethylene Co., Ltd.]

[0057] (a2) Ethylene-unsaturated ester copolymer ["Evaflex EV180" manufactured by Mitsui DuPont Polymer Chemical Co., Ltd.: Density 0.94 g / cm 3 , ethylene-vinyl acetate copolymer (containing vinyl acetate 33% by weight)]

[0058] (a3) Vinyl resins containing acid anhydride groups ["ADTEXL6101M" manufactured by Nippon Polyethylene Co., Ltd.: Density 0.92 g / cm 3 , LLDPE (maleic anhydride modified linear low density polyethylene) containing 0.2 wt% maleic anhydride groups]

[0059] (a4) Silane-graf...

manufacture example 1

[0094] Production example 1 [production of (a4) and (a5)]

[0095] Dissolve dicumyl peroxide (DCP) in vinylmethoxysilane, use two kinds of polyethylene resins (a1) and (a2) respectively, stir and mix with the composition ratio (parts by weight) of Table 1, Extrusion was performed at an extrusion temperature of 150 to 200° C. using a single-screw extruder with a diameter of 50 mm to obtain pellets (a4) and (a5). Each resin is sealed and packaged in an aluminum foil laminated bag, stored in a state of isolating external moisture, and taken out for use as needed.

[0096] [Table 1]

[0097] Material a4 a5 Vinylmethoxysilane 3 3 DCP 0.2 0.2 a1 100 - a2 - 100

Embodiment 1~6 and comparative example 1~5

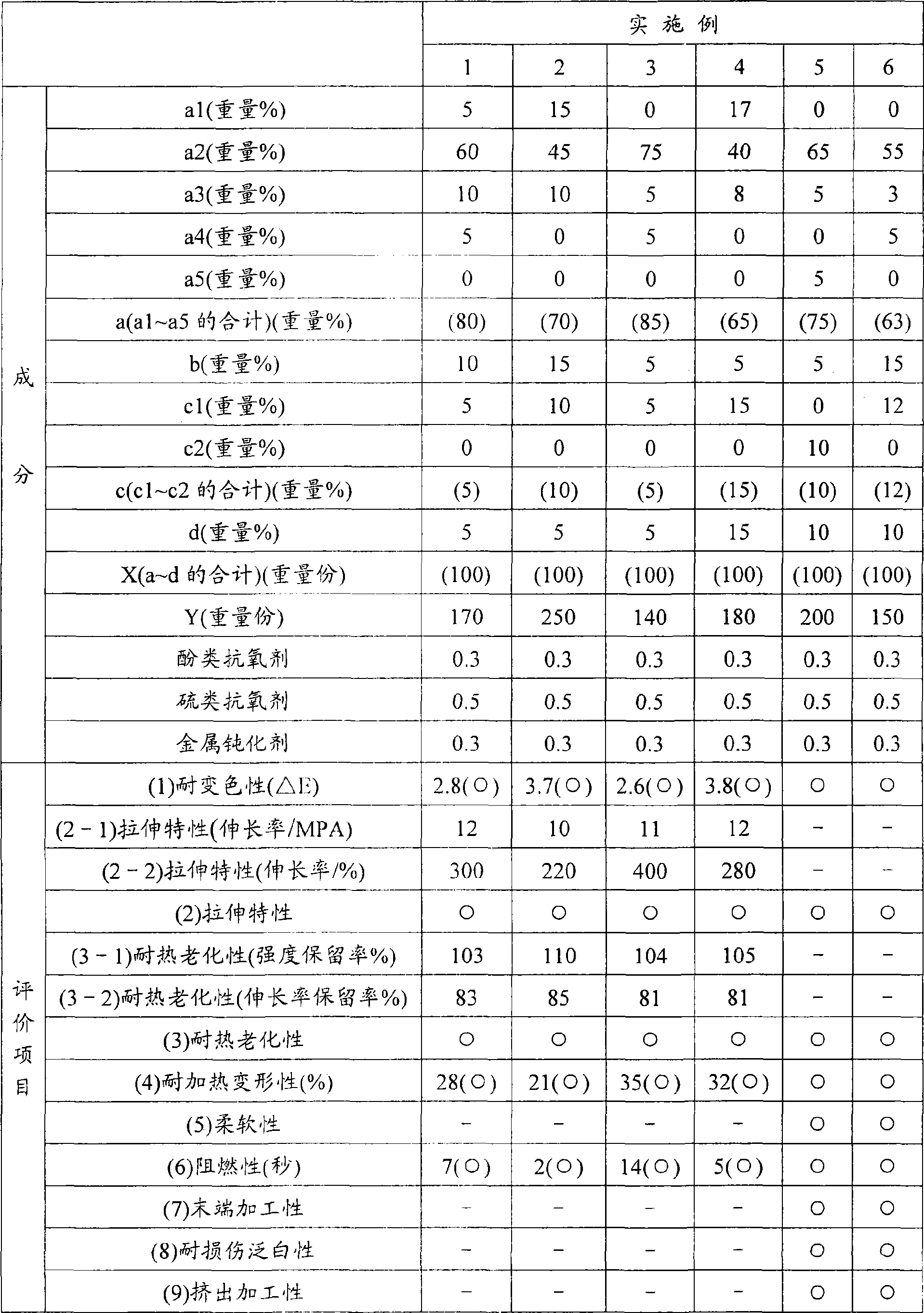

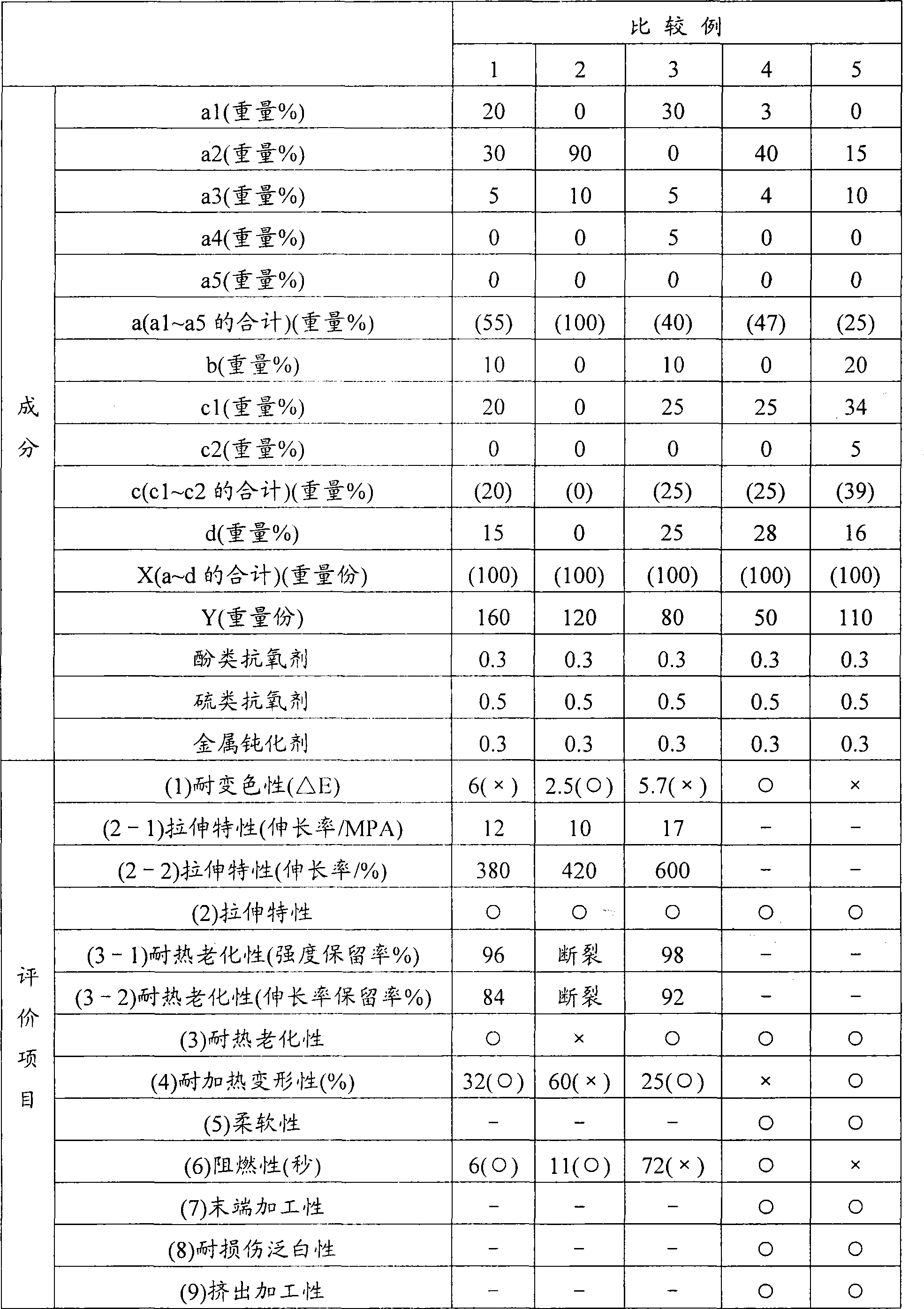

[0099] Mixtures of the various formulations shown at the top of Tables 2 and 3 were made. Mixing is carried out with a kneader mixer, the kneading temperature is set at 180-230° C., and granulation is carried out after mixing. Table 2 and Table 3 show the evaluation results of each mixture.

[0100] [Table 2]

[0101]

[0102] [table 3]

[0103]

[0104] It can be seen from Table 2 and Table 3 that the materials shown in the examples exhibit good discoloration resistance, mechanical strength, heat resistance, flexibility, flame retardancy, end processability, damage whitening resistance and molding processability. On the other hand, none of the comparative examples could achieve the balance of the aforementioned properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com