Halogen free phosphorous-nitrogen synergic antiflaming water-soluble polyurethane fabric coating agent and preparation method thereof

A water-based polyurethane and synergistic flame-retardant technology, which is applied in the field of light industry, can solve the problems of large smoke generation, and achieve the effect of transparent coating and remarkable flame-retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The formula of halogen-free phosphorus-nitrogen synergistic flame-retardant waterborne polyurethane fabric coating agent is shown in table 1:

[0029] Table 1 Example 1 The formula of halogen-free phosphorus-nitrogen synergistic flame-retardant waterborne polyurethane fabric coating agent

[0030] raw material

Mass / g

Isophorone diisocyanate

138

Polyester polyol (hydroxyl value 110mgKOH / g)

110

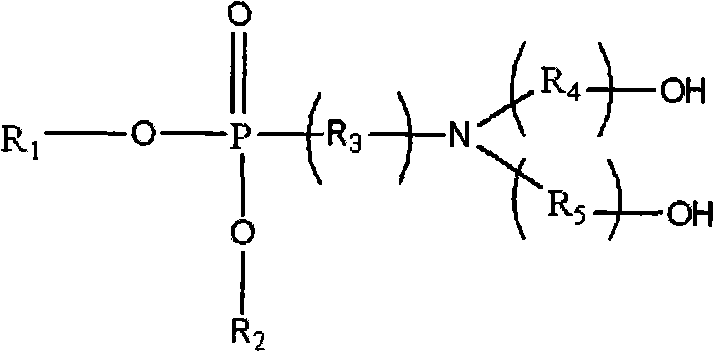

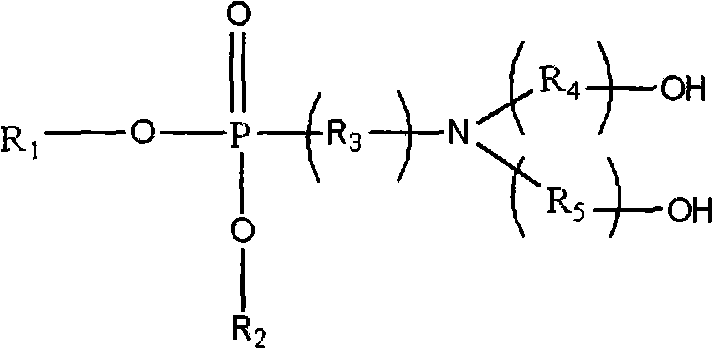

N-hydroxymethyl, N-hydroxypropylaminomethylphosphonic acid diethyl ester (hydroxyl value 450mgKOH / g)

75

28

9.1

[0031] 1) Add isophorone diisocyanate, polyester polyol with a hydroxyl value of 110mgKOH / g, and N-methylol with a hydroxyl value of 450mgKOH / g in a four-necked flask equipped with a stirrer, a reflux condenser, and a thermometer. , N-hydroxypropylaminomethylphosphonic acid diethyl ester and dimethylol propionic acid, at 75 ° C in N 2 Under the protecti...

Embodiment 2

[0036] The formula of halogen-free phosphorus-nitrogen synergistic flame-retardant waterborne polyurethane fabric coating agent is shown in table 2:

[0037] Table 2 Example 2 The formula of halogen-free phosphorus-nitrogen synergistic flame-retardant waterborne polyurethane fabric coating agent

[0038] raw material

Mass / g

Toluene diisocyanate

119

[0039] Polyether polyol (hydroxyl value 100mgKOH / g)

100

N-hydroxymethyl, N-hydroxyethylaminoethylphosphonic acid dimethyl ester (hydroxyl value 435mgKOH / g)

84

17.3

9.3

[0040] 1) Add toluene diisocyanate, polyether polyol with a hydroxyl value of 100mgKOH / g, N-methylol with a hydroxyl value of 435mgKOH / g, N- Dimethyl hydroxyethylaminoethylphosphonate and dimethylolpropionic acid, at 75°C in N 2 Under the protection reaction 5h, obtain prepolymer;

[0041] 2) Cool the prepolymer obtained in step 1) to ...

Embodiment 3

[0045] The formula of halogen-free phosphorus-nitrogen synergistic flame-retardant waterborne polyurethane fabric coating agent is shown in table 3:

[0046] Table 3 Example 3 The formula of halogen-free phosphorus-nitrogen synergistic flame-retardant waterborne polyurethane fabric coating agent

[0047] raw material

Mass / g

112

Polyether polyol (hydroxyl value 100mgKOH / g)

100

Dimethyl bis(hydroxymethyl)aminoethylphosphonate (hydroxyl value 410mgKOH / g)

62.4

12

9.1

[0048] 1) Add hexamethylene diisocyanate, polyether polyol with a hydroxyl value of 100mgKOH / g, and bis(hydroxymethyl) with a hydroxyl value of 410mgKOH / g in a four-necked flask equipped with a stirrer, a reflux condenser, and a thermometer. ) Dimethyl aminoethylphosphonate and dimethylolpropionic acid, at 75°C in N 2 Reaction 5h under protection obtains prepolymer;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com