Flame-retardant high-temperature vulcanized silicone rubber strips for doors and windows of buildings and preparation method thereof

A technology of high temperature vulcanization, building doors and windows, applied in the direction of sealing devices, etc., can solve the problems of personnel hazards and secondary pollution of the environment, and achieve the effects of good fire resistance, high flame retardant efficiency, and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

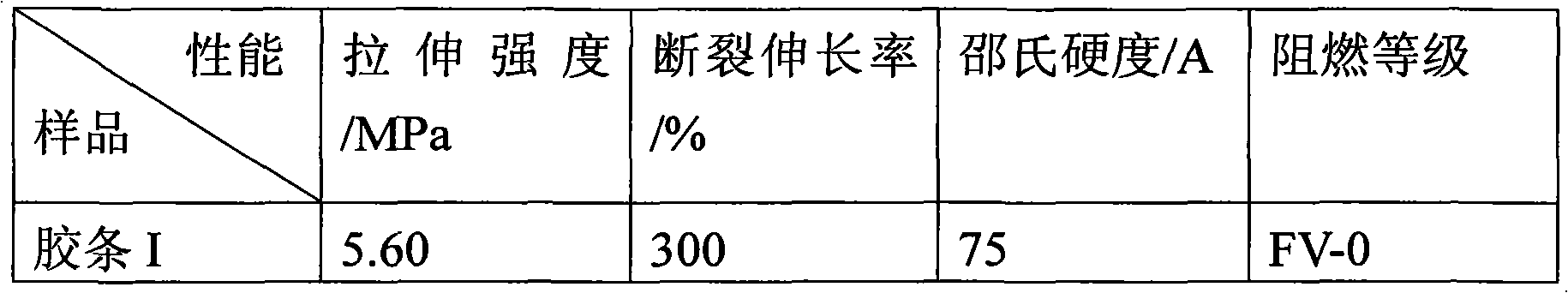

Embodiment 1

[0035] In the kneader, add 100 parts by weight of methyl vinyl silicone rubber with a vinyl content of 0.16mol% and a molecular weight of 500,000, and then add 6 parts by weight of hydroxyl silicone oil with a viscosity of 4000mPa.s, white carbon black of 50 parts by weight and 150 parts by weight of activated aluminum hydroxide were kneaded for 4 hours at a temperature of 100°C and a vacuum of -0.10 MPa to obtain a mixed rubber. Cool the above-mentioned rubber compound to room temperature, add 0.5 part of color masterbatch and 1 part of vulcanizing agent 2,4-dichlorobenzoyl peroxide to 100 parts by weight of the mixed rubber, and pass it 5 times on the open mill to prepare Get mixed rubber film. Cut the film into 4 cm, feed it into the extruder, extrude the strip, and vulcanize the extruded strip in a high-temperature vulcanization oven at 200°C; put the vulcanized strip into an oven at 180°C for curing After secondary vulcanization, flame-retardant high-temperature vulcaniz...

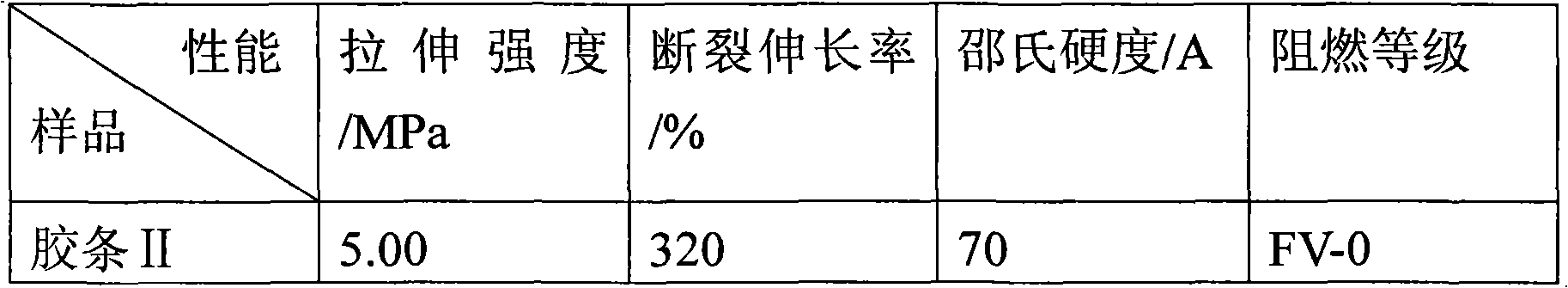

Embodiment 2

[0039] Add 100 parts by weight of methyl vinyl silicone rubber with a vinyl content of 0.23mol% and a molecular weight of 700,000, 150 parts by weight of white carbon black, 70 parts by weight of aluminum hydroxide, and 10 parts by weight of hydroxyl silicone oil with a viscosity of 300mPa.s Kneading machine, kneading at 180°C, vacuum degree -0.06MPa for 2 hours, cooled to room temperature, to obtain mixed rubber. The above-mentioned mixed rubber is cooled to room temperature, 1.5 parts of color masterbatch and 3 parts of vulcanizing agent benzoyl peroxide are added to 100 parts by weight of the mixed rubber, and the mixed rubber film is obtained after passing through the mill for 3 times. Cut the film into 6 cm, feed it into the extruder, extrude the strip, and vulcanize the extruded strip in a high-temperature vulcanization oven at 270°C; put the vulcanized strip into an oven at 220°C for curing Secondary vulcanization to prepare flame-retardant high-temperature vulcanized s...

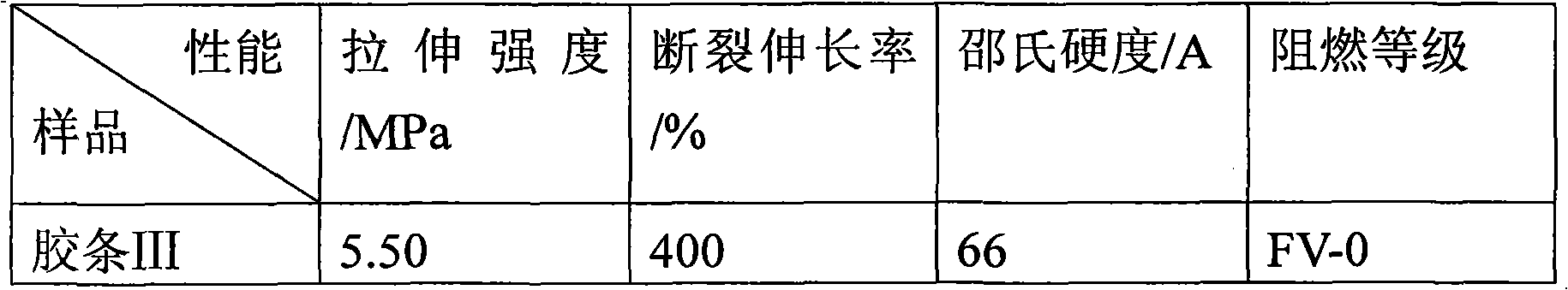

Embodiment 3

[0043] Add 100 parts by weight of methyl vinyl silicone rubber with a vinyl content of 0.18mol% and a molecular weight of 600,000 in the kneader, then add 8 parts by weight of hydroxyl silicone oil with a viscosity of 1000mPa.s, and 100 parts by weight of white carbon black and 100 parts by weight of active magnesium hydroxide were kneaded for 0.5 hour at a temperature of 120°C and a vacuum of -0.08MPa to obtain a rubber compound. The above-mentioned mixed rubber is cooled to room temperature, 1 part of color masterbatch and 2 parts of vulcanizing agent dicumyl peroxide are added to 100 parts by weight of the mixed rubber, and the mixed rubber film is obtained after thinly passing 4 times on the open mill . Cut the film into 5 cm, feed it into the extruder, extrude the strip, and vulcanize the extruded strip in a high-temperature vulcanization oven at 230°C; put the vulcanized strip into an oven at 200°C for curing Secondary vulcanization to prepare flame-retardant high-tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com