High-temperature vulcanized silicone rubber sealing strip and preparation method thereof

A technology of high-temperature vulcanization and silicone rubber, which is applied in the field of building materials, can solve problems such as the gap between tensile strength and tear strength, tearing, poor tensile strength and tear strength, etc., and achieve excellent mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

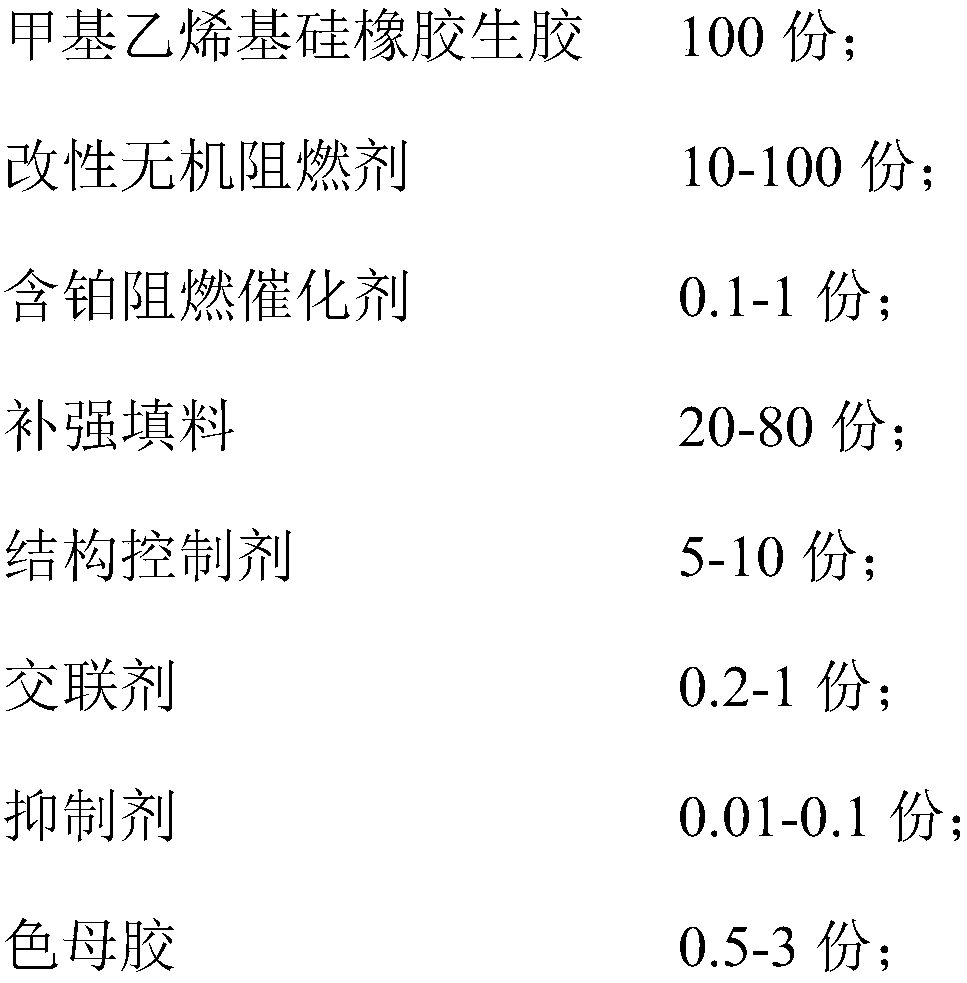

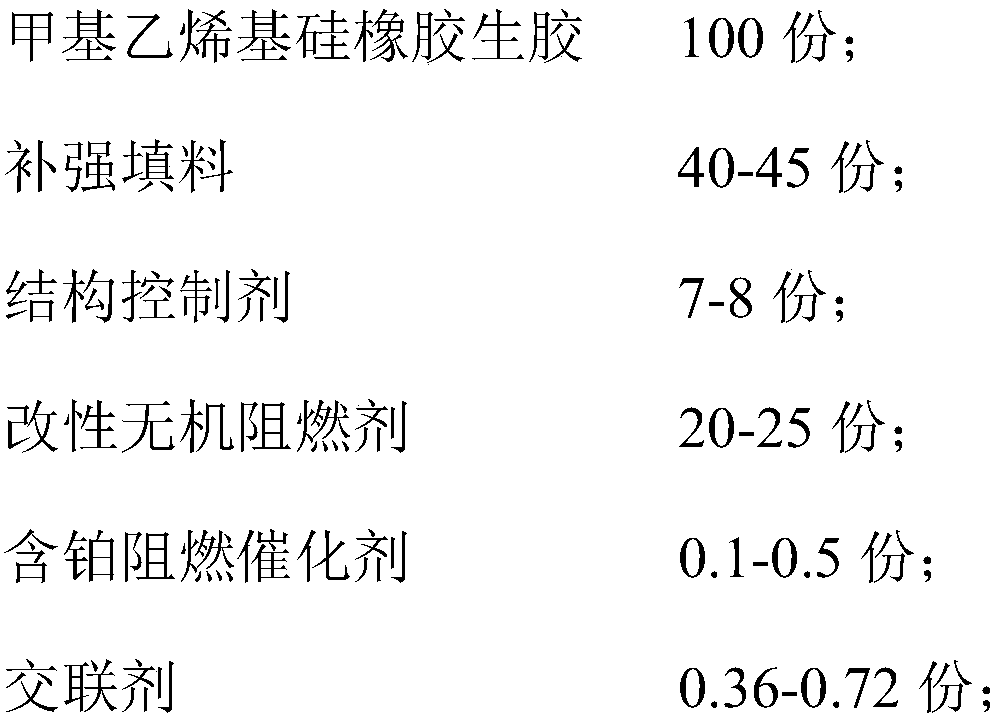

Method used

Image

Examples

Embodiment 1

[0044] 1. Preparation of modified inorganic flame retardant:

[0045] Put 100g of aluminum hydroxide (with a particle size of 1-8μm) into a forced air constant temperature drying oven at 110°C for 4 hours, then put it into a flask, add 18g of tetramethyldivinyldisilazane into the flask, Stir rapidly at ℃ for 1 hour, and then put it into a blower constant temperature drying oven for 4 hours at 120 ℃ to prepare a modified inorganic flame retardant.

[0046] 2. Preparation of platinum-containing flame retardant catalyst:

[0047] Make a solution of chloroplatinic acid and octanol in a molar ratio of 1:2, and stir at 70°C and 3KPa for 5h. Then the precipitate was filtered out, and the filtrate was stirred at 70° C. and 0.2 KPa for 2 h to obtain a platinum compound.

[0048] The specific surface area is 80m 2 / g of fumed silica and the above-mentioned platinum compound are uniformly mixed in a weight ratio of 100:100, placed at room temperature for more than 10 hours, and dilute...

Embodiment 2

[0063] 1. Preparation of modified inorganic flame retardant:

[0064] Put 100g of aluminum hydroxide (with a particle size of 1-8μm) into a forced air constant temperature drying oven at 110°C for 4 hours, then put it into a flask, add 20g of tetramethyldivinyldisilazane into the flask, Stir rapidly at ℃ for 1 hour, and then put it into a blower constant temperature drying oven for 4 hours at 120 ℃ to prepare a modified inorganic flame retardant.

[0065] 2. Preparation of platinum-containing flame retardant catalyst:

[0066] Make a solution of chloroplatinic acid and octanol in a molar ratio of 1:2, and stir at 70°C and 3KPa for 5h. Then the precipitate was filtered out, and the filtrate was stirred at 70° C. and 0.2 KPa for 2 h to obtain a platinum compound.

[0067] The specific surface area is 80m 2 / g of fumed silica and the above-mentioned platinum compound are uniformly mixed in a weight ratio of 100:300, placed at room temperature for more than 10 hours, and dilute...

Embodiment 3

[0076] 1. Preparation of modified inorganic flame retardant:

[0077] Put 100g of aluminum hydroxide (with a particle size of 1-8μm) in a forced air constant temperature drying oven at 110°C for 4 hours, then put it into a flask, add 23g of tetramethyldivinyldisilazane to the flask, Stir rapidly at ℃ for 1 hour, and then put it into a blower constant temperature drying oven for 4 hours at 120 ℃ to prepare a modified inorganic flame retardant.

[0078] 2. Preparation of platinum-containing flame retardant catalyst:

[0079] Make a solution of chloroplatinic acid and octanol in a molar ratio of 1:2, and stir at 70°C and 3KPa for 5h. Then the precipitate was filtered out, and the filtrate was stirred at 70° C. and 0.2 KPa for 2 h to obtain a platinum compound.

[0080] The specific surface area is 80m 2 / g of fumed silica and the above-mentioned platinum compound are uniformly mixed in a weight ratio of 100:50, placed at room temperature for more than 10 hours, and diluted wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com