High-temperature resistant wear-resistant irradiation cross-linked regenerated-polyolefin/nano-magnesium-hydroxide halogen-free flame-retardant environmental-friendly cable material with high electric properties and production method of the cable material

A technology of nano-magnesium hydroxide and nano-flame retardant, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., to achieve significant economic benefits, enhanced dispersion, and significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 (production of power cables)

[0032] A high-temperature-resistant, wear-resistant, high-electricity, radiation-crosslinked regenerated polyolefin / nano-magnesium hydroxide, halogen-free, flame-retardant, and environment-friendly cable material, which is prepared from raw materials with the following weight components: 40 parts of regenerated polyolefin, equivalent to 40 parts of container agent, 20 parts of EPDM, 120 parts of nano-flame retardant, 5 parts of smoke agent, 3 parts of sensitizer; 1 part of coupling agent, 1.0 part of antioxidant, 1.5 parts of lubricant , 2.5 parts of colorant. The compatibilizer is ethylene-vinyl acetate copolymer grafted with maleic anhydride; EPDM is 4725P; the nano-flame retardant is environmentally friendly nano-magnesium hydroxide; the smoke agent is molybdenum trioxide; the sensitizer It is TAIC triallyl isocyanurate; the coupling agent is silane coupling agent A-172; the antioxidant is 1076; the lubricant is fluorine l...

Embodiment 2

[0036] Example 2 is the same as Example 1, except that the EPDM is Nordel2722, the antioxidant is 300, and the material properties are shown in Table 1.

Embodiment 3

[0038] Example 3 is the same as Example 1, except that the ethylene propylene diene monomer (EPDM) is 4045, the lubricant is polyethylene wax, and the material properties are shown in Table 1.

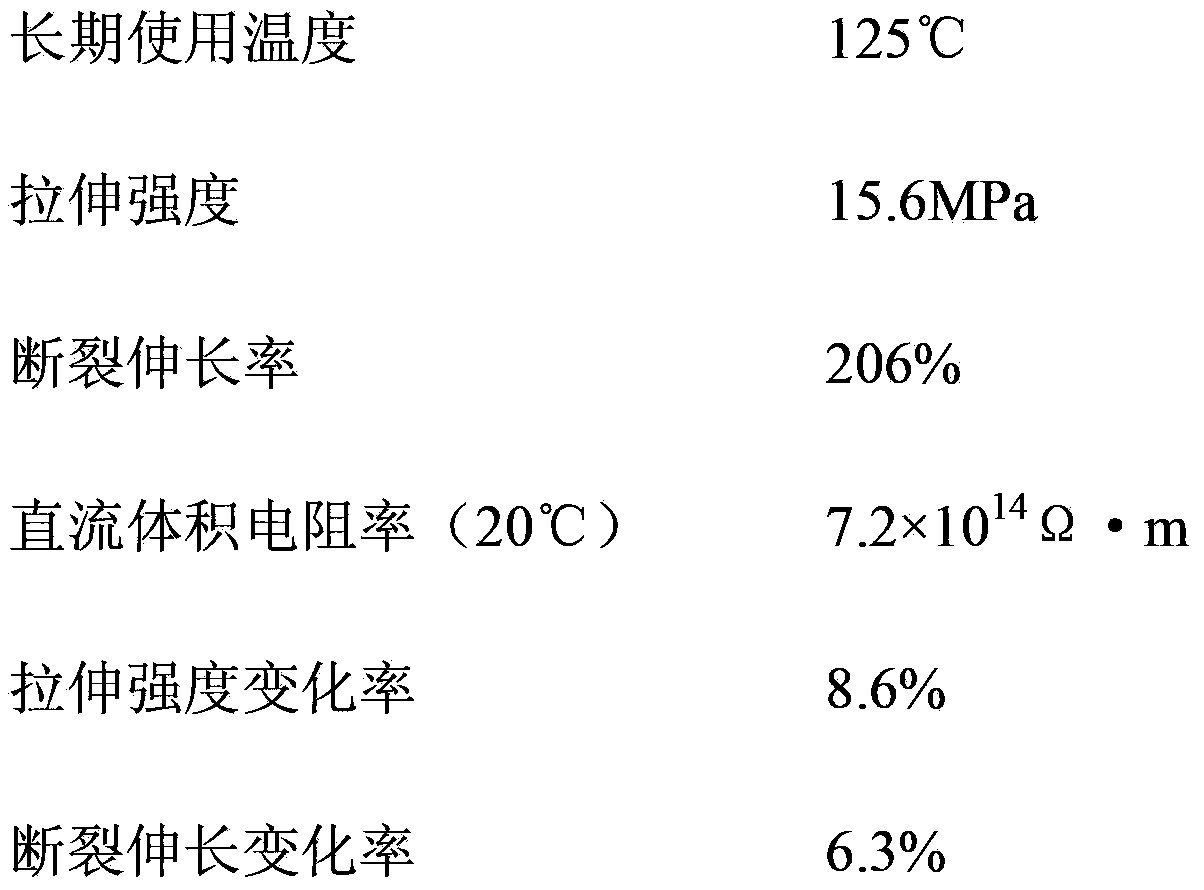

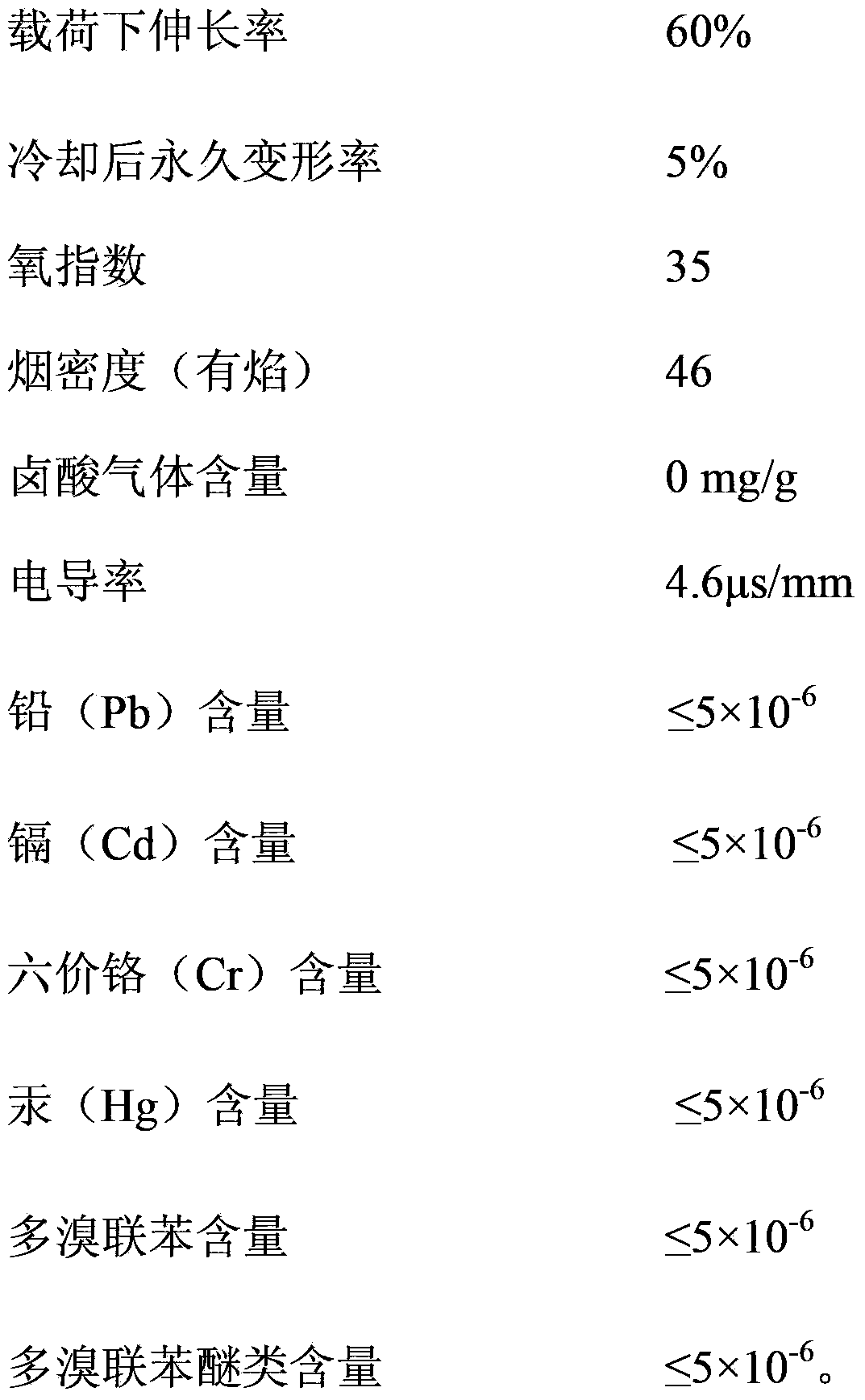

[0039] Table 1 is the experimental performance of embodiment 1-3

[0040] Experimental content Example 1 Example 2 Example 3 rate of change of tensile strength 8.8% 7.6% 8.4% Elongation at break rate of change 6.7% 5.8% 6.6% elongation under load 58% 57% 60% permanent deformation after cooling 3% 2% 2%

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com