Preparation method of flame-retardant organic/inorganic composite membrane

An inorganic composite and organic technology, applied in the field of high-performance diaphragm preparation, can solve the problems of poor pore formation uniformity, limited flame retardant effect, high price, etc., and achieve the effects of low equipment requirements, low cost, and easily controllable conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

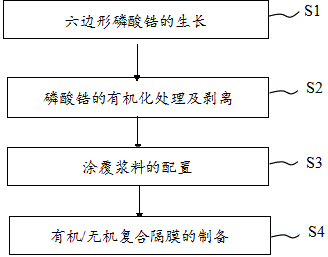

[0047] The embodiment of the present invention provides a method for preparing a flame-retardant organic / inorganic composite diaphragm containing a hexagonal zirconium phosphate coating layer. Including the following steps:

[0048] S01. Hexagonal zirconium phosphate

[0049] In a hydrothermal reactor, zirconium phosphate with a stable hexagonal structure was prepared by a time-temperature-concentration control method.

[0050] S02. Organic zirconium phosphate:

[0051] Use an organic stripping agent to peel off the hexagonal sheet-shaped zirconium phosphate, and add an organic segment to the surface of the zirconium phosphate to form an active zirconium phosphate with an organophilic phase;

[0052] S03. Configuration of Coating Slurry

[0053] The organic zirconium phosphate solution and the binder solution are directly mixed and stirred at a high speed to prepare a coating slurry; wherein, the mass ratio of the organic zirconium phosphate to the binder is 10-200:1;

[0...

Embodiment 1

[0067] S11 Mix zirconium oxychloride and phosphoric acid with a mass ratio of 1:5 and pour them into an autoclave, react in an oven at 150°C for 20 hours, cool to room temperature, wash with water until neutral, and dry in an oven to obtain initial six Polygonal zirconium phosphate powder;

[0068] S12 Disperse zirconium phosphate in ethylamine solution and pre-disperse for 1 hour, then add organic stripping agent cetyl trimethyl ammonium hydrogen sulfate, the mass ratio of zirconium phosphate to organic stripping agent is 0.5:1, and the stripping time is 15 hours , diluted to pH 8 after the reaction was completed.

[0069] S13 Mix the polyvinyl alcohol aqueous solution with a mass fraction of 10% and the organic zirconium phosphate aqueous solution at room temperature, and stir for 12 hours, wherein the mass ratio of the organic zirconium phosphate to polyvinyl alcohol is 17:1.

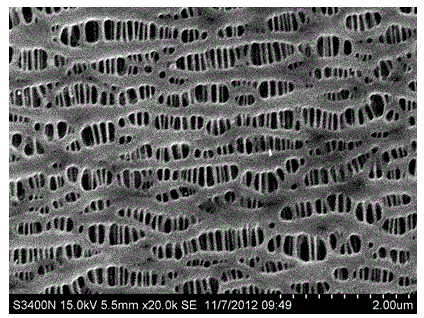

[0070] S14: Soak the dry-process PP microporous membrane in the slurry for 30 minutes, take it o...

Embodiment 2

[0073] S21 Mix zirconium oxychloride and phosphoric acid with a mass ratio of 1:13 and pour them into an autoclave, react in an oven at 190°C for 30 hours, cool to room temperature, wash with water until neutral, and dry in an oven to obtain the initial six Polygonal zirconium phosphate powder;

[0074] S22 Disperse zirconium phosphate in aniline solution and pre-disperse for 1.5 hours, then add organic stripping agent sodium lauryl sulfate, the mass ratio of zirconium phosphate to organic stripping agent is 0.9:1, and the stripping time is 20 hours. After the reaction is completed, dilute to pH 8.

[0075] S23 Mix an aqueous solution of methyl cellulose with a mass fraction of 20% and an aqueous solution of organic zirconium phosphate at room temperature, and stir for 12 hours, wherein the mass ratio of organic zirconium phosphate to methyl cellulose is 23:1.

[0076] S24: Soak the dry PE microporous membrane in the slurry for 30 minutes, take it out and dry it in a vacuum o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com