Synthesis of nitrogen and sulfur-containing synergistic flame retardant compound and preparation method of intercalated modified hydrotalcite thereof

A technology of synergistic flame retardant and synthesis method, which is applied in the fields of dyeing low-molecular organic compound treatment, organic chemistry, and fibrous fillers. It can solve the problems that the preparation method of composite flame retardant materials has not been reported, and achieve good application value and improve Dispersion, the effect of simple and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take 7.52g of dimethylamine water and mix it with 100mL of toluene. Take 9.22g of cyanuric chloride and mix it with 50mL of toluene. Add the above two solutions dropwise into a beaker, and react at 0-5°C for 2h. With hydrochloric acid, NaHCO 3 , washed with deionized water, and rotary evaporated, and the obtained solid was recrystallized with n-hexane, filtered with suction, and dried to obtain a triazine monosubstituted product (NN).

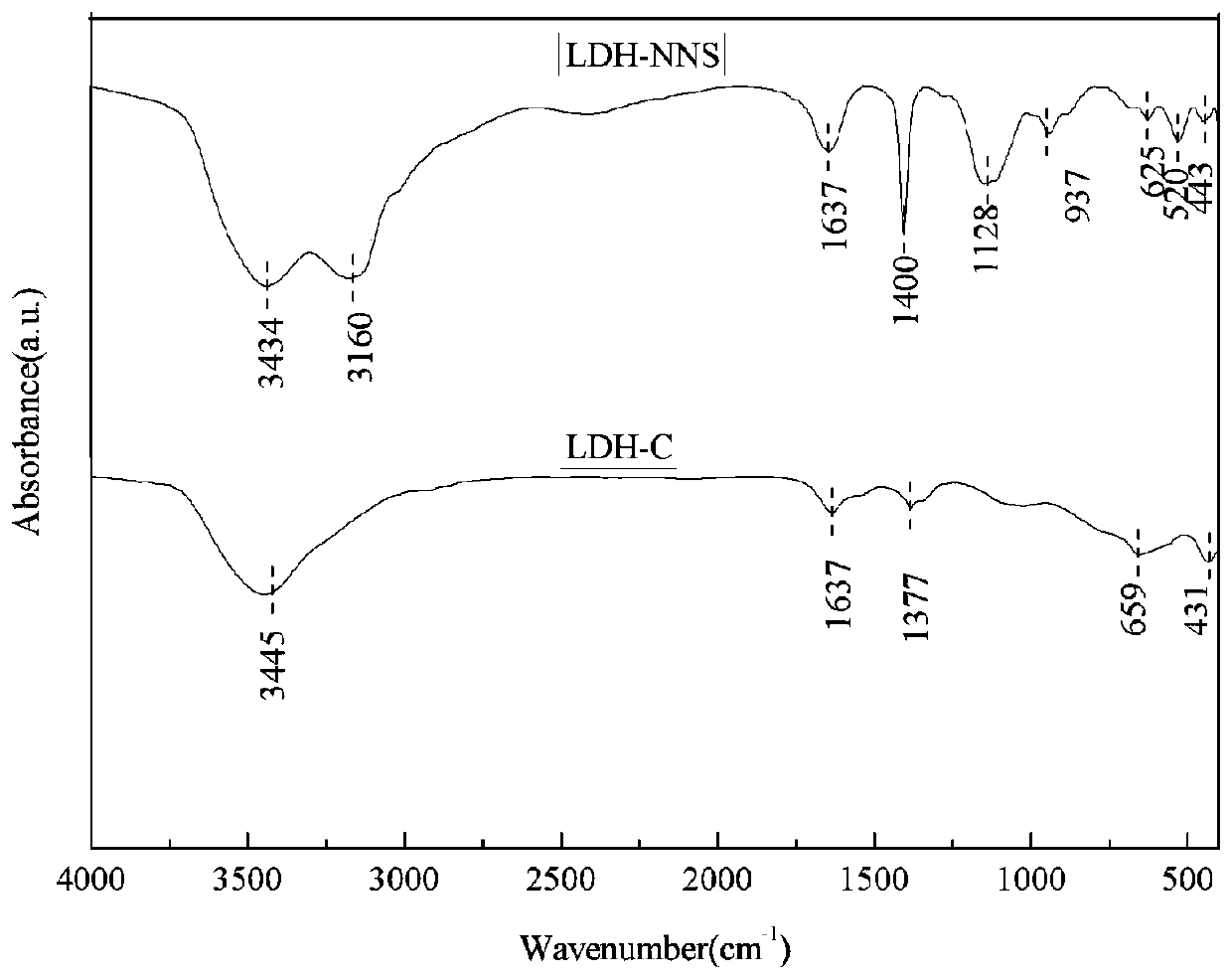

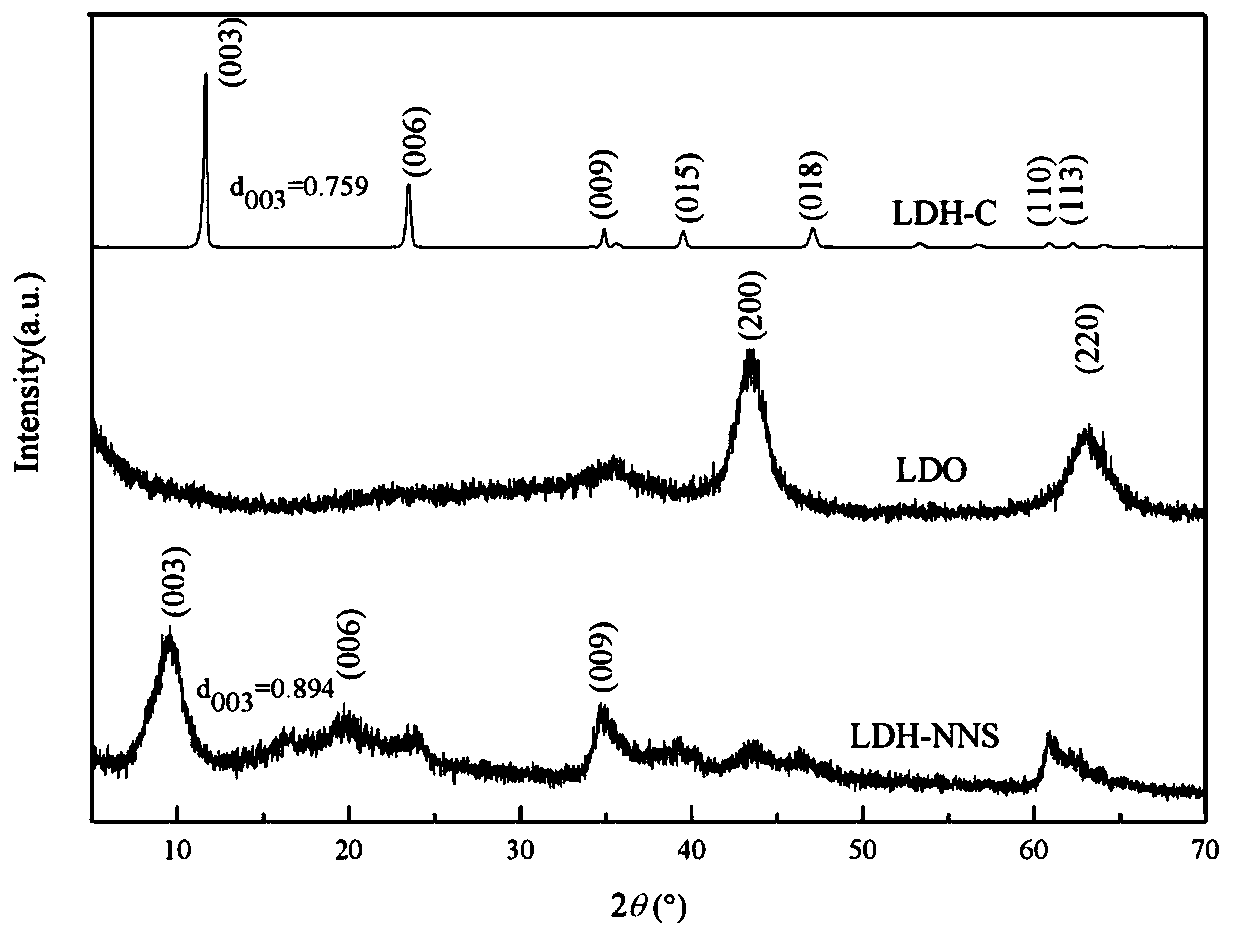

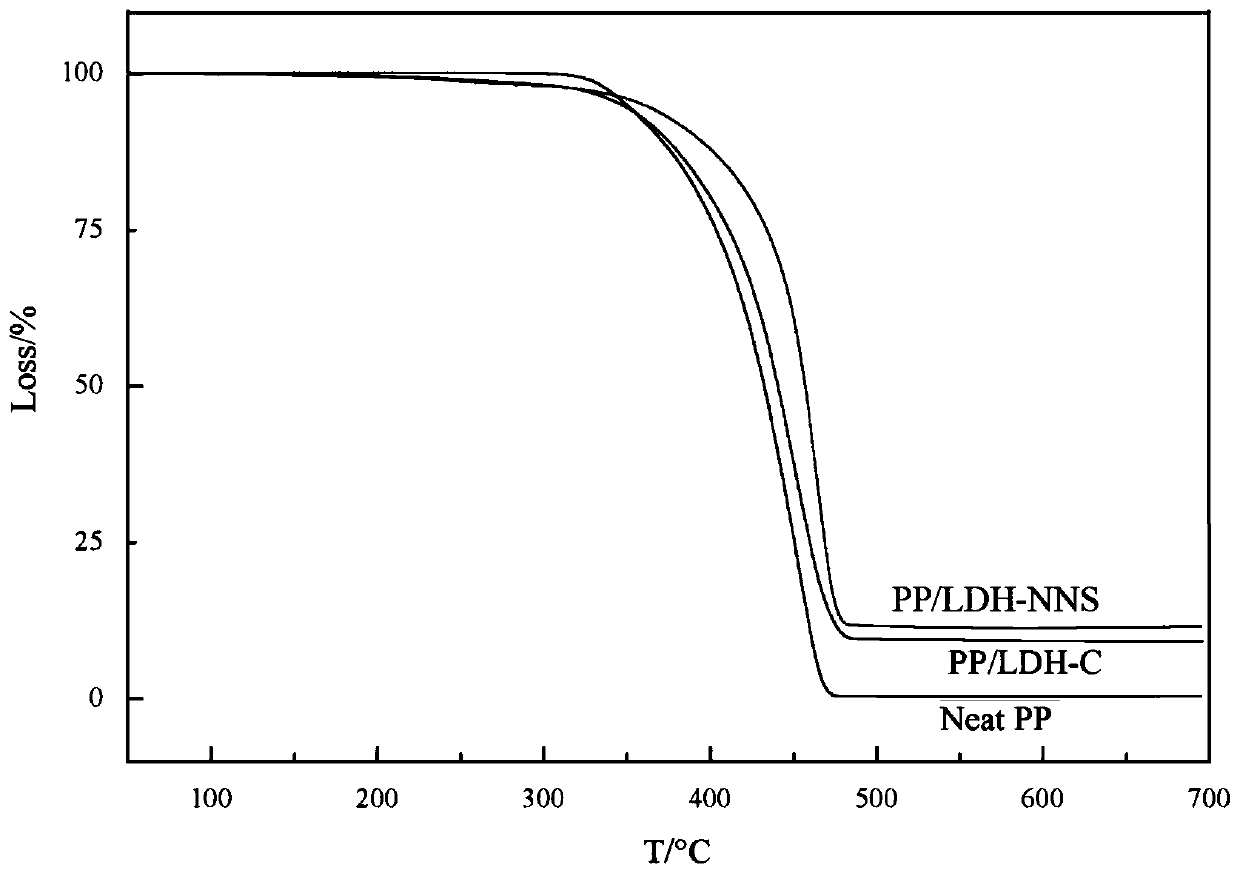

[0036] Take 0.8gNN, 2.1g anhydrous Na 2 SO 4 , and stir well with 100mL 1,4-dioxane in the flask. Dissolve 1.25g of taurine in 50mL of water, drop the taurine solution into the flask, and heat to 60°C for 6h. Rotary steaming, then add 100mL deionized water to the beaker, react at 90°C for 48 hours, rotary steaming, recrystallize the solid with ultrapure water, suction filter, dry to obtain nitrogen-sulfur synergistic flame retardant compound (NNS), the reaction formula is as follows:

[0037]

[0038] Accurately weigh Mg(NO 3 )...

Embodiment 2

[0042] Take 7.52g of dimethylamine water and mix it with 100mL of toluene. Take 9.22g of cyanuric chloride and mix it with 50mL of toluene. Add the above two solutions dropwise into a beaker, and react at 0-5°C for 2h. With hydrochloric acid, NaHCO 3 , washed with deionized water, and rotary evaporated, and the obtained solid was recrystallized with n-hexane, filtered with suction, and dried to obtain a triazine monosubstituted product (NN).

[0043] Take 0.8gNN, 2.1g anhydrous Na 2 SO 4 , and stir well with 100mL 1,4-dioxane in the flask. Dissolve 1.25g of taurine in 50mL of water, drop the taurine solution into the flask, and heat to 60°C for 6h. Rotary evaporation, then add 100mL deionized water to the beaker, react at 90°C for 48h, rotary evaporation, recrystallize the solid with ultrapure water, suction filter, and dry to obtain the nitrogen-sulfur synergistic flame retardant compound (NNS).

[0044] Accurately weigh Zn(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O ...

Embodiment 3

[0048] Take 7.52g of dimethylamine water and mix it with 100mL of toluene. Take 9.22g of cyanuric chloride and mix it with 50mL of toluene. Add the above two solutions dropwise into a beaker, and react at 0-5°C for 2h. With hydrochloric acid, NaHCO 3 , washed with deionized water, and rotary evaporated, and the obtained solid was recrystallized with n-hexane, filtered with suction, and dried to obtain a triazine monosubstituted product (NN).

[0049] Take 0.8gNN, 2.1g anhydrous Na 2 SO 4 , and stir well with 100mL 1,4-dioxane in the flask. Dissolve 1.25g of taurine in 50mL of water, drop the taurine solution into the flask, and heat to 60°C for 6h. Rotary evaporation, then add 100mL deionized water to the beaker, react at 90°C for 48h, rotary evaporation, recrystallize the solid with ultrapure water, suction filter, and dry to obtain the nitrogen-sulfur synergistic flame retardant compound (NNS).

[0050] Accurately weigh Ni(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com