Durable biomass polyphenol water-based flame retardant paint and preparation method and applications thereof

A polyphenol water-based, flame-retardant coating technology, used in fire-retardant coatings, polyester coatings, flame-retardant fibers, etc., can solve the problems of non-washability, non-durability, and high protein cost, and achieve low prices and reduce production. Cost, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

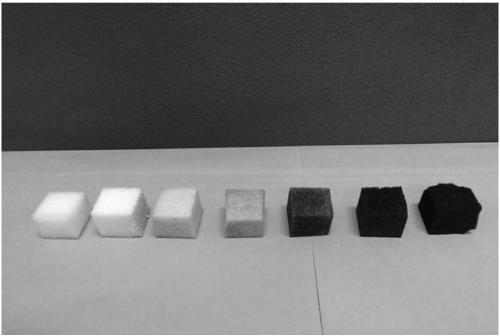

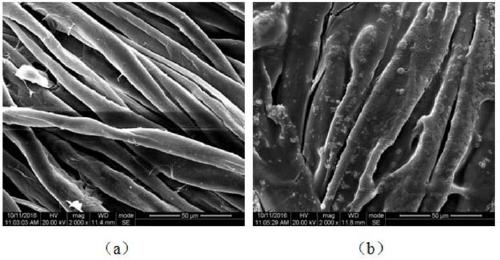

Examples

Embodiment 1

[0066] First add 0.1mol catechol to an appropriate amount of water and stir at 60°C for 15 minutes, then add 0.5 times the polyacrylic acid emulsion based on the mass of catechol, and finally add water and stir to make the mass concentration of polyphenolic compounds in the obtained liquid When it reaches 1%, a durable biomass polyphenol water-based flame-retardant coating can be obtained.

Embodiment 2

[0068] First add 0.1mol epigallocatechin to an appropriate amount of water and stir at 60°C for 25 minutes, then add dropwise chromium nitrate with a ratio of 1:4 of the amount of epigallocatechin to the amount of chromium nitrate under stirring conditions Liquid, stirring and reacting for 50 minutes after dripping to obtain a gray-green liquid, then, based on the mass of epigallocatechin, add 1.5 times of its bisphenol A epoxy resin, and finally add water and stir to make the polyphenol compound in the gained liquid When the mass concentration reaches 1%, a durable biomass polyphenol water-based flame-retardant coating can be obtained.

Embodiment 3

[0070] First, add 0.1mol catechol into appropriate amount of water and stir at 60°C for 25 minutes, then add dropwise the chromium nitrate liquid with the ratio of the amount of catechol substance to the amount of chromium nitrate substance at a ratio of 1:6 under the condition of stirring, and the drop is completed Stir and react for 50 minutes to obtain a gray-green liquid, then add 1.5 times the phenolic resin based on the mass of catechol, and finally add water and stir to make the mass concentration of the polyphenol compound in the obtained liquid reach 1%. Non-toxic biomass polyphenol water-based flame retardant coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com