Fire retardant curtain

A technology of curtains and flame retardant liquid, applied in the direction of curtains, tents, window decorations, etc., can solve the problems of poor flame retardant effect, extremely easy to burn curtains, complicated flame retardant treatment process, etc., to eliminate fire hazards , The flame retardant treatment process is simple and the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

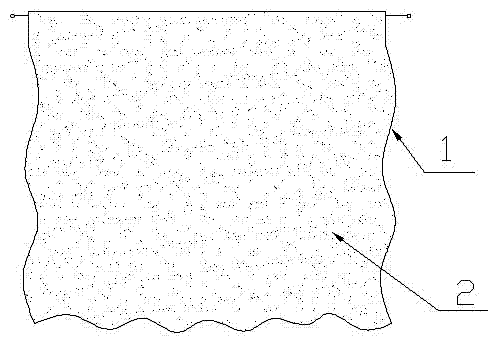

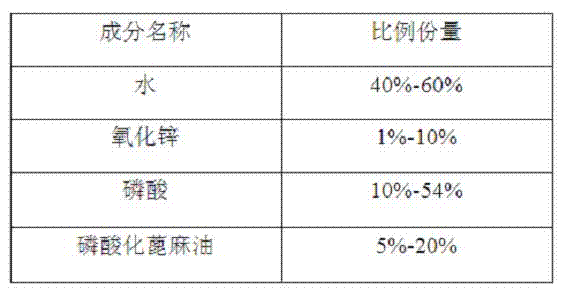

[0010] Example 1: When treating curtains (1), provide a flame retardant solution (2), its specific composition by weight percentage is: 40% water, 1% zinc oxide, 54% phosphoric acid, 5% phosphorylated castor oil , place the curtain (1) in the provided flame retardant solution (2) for soaking treatment, then dry it, then spray the flame retardant solution (2) on the curtain (1), and dry it at room temperature , and then to achieve the effect of flame retardant curtains.

Embodiment 2

[0011] Example 2: When treating curtains (1), provide a flame retardant solution (2), its specific composition by weight percentage is: water 60%, zinc oxide 10%, phosphoric acid 10%, phosphorylated castor oil 20% , place the curtain (1) in the provided flame retardant solution (2) for soaking treatment, then dry it, then spray the flame retardant solution (2) on the curtain (1), and dry it at room temperature , to achieve the effect of flame retardant curtains.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com