Reinforced flame-retardation PBT/PA6 composite material and preparation method thereof

A composite material and pre-mixing technology, applied in the field of modification of engineering plastics, can solve problems such as incompatibility, and achieve the effects of improving compatibility, preventing glass fiber from being exposed, and improving rigidity and impact strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

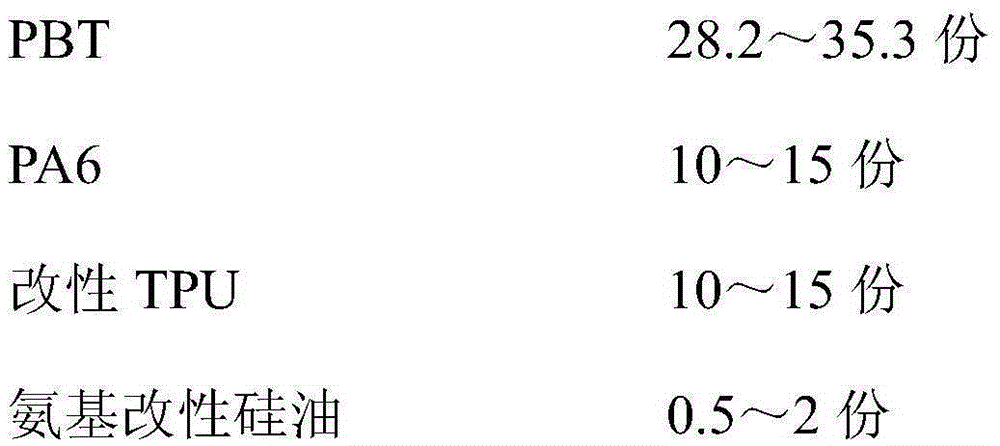

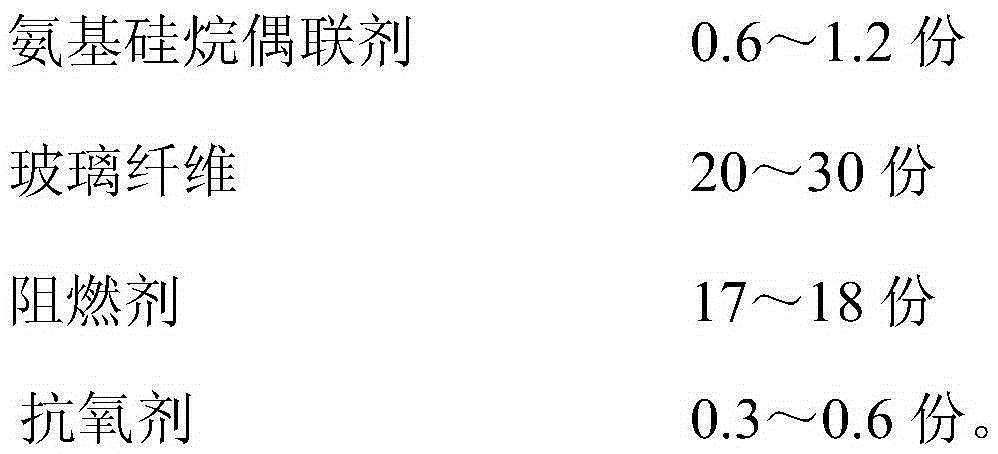

Method used

Image

Examples

preparation example Construction

[0028] The preparation method comprises steps:

[0029](1) Premixing: Add PBT, PA6, modified TPU, composite flame retardant, antioxidant, etc. into a high-speed mixer in sequence for premixing, the mixing temperature is 30-50°C, and the speed is 100-800 rpm. The mixing time is 1-5 minutes to become material A; then add glass fiber, amino-modified silicone oil, and aminosilane coupling agent to a low-speed mixer for mixing. The mixing temperature is 30-40°C and the rotation speed is 50-100 rpm , the mixing time is 5 to 15 minutes, and it becomes material B;

[0030] (2) Extrusion granulation: Add the premixed material A from the main feeder to a twin-screw extruder with an aspect ratio of 35 to 45, and add material B such as glass fiber from the side feeder, and melt and extrude For granulation, the screw speed is 100-300 rpm, and the main feeder speed is 10-60 rpm. The temperature of each section of the extruder is 180-280°C.

[0031] The dried reinforced PBT / PA6 composite ...

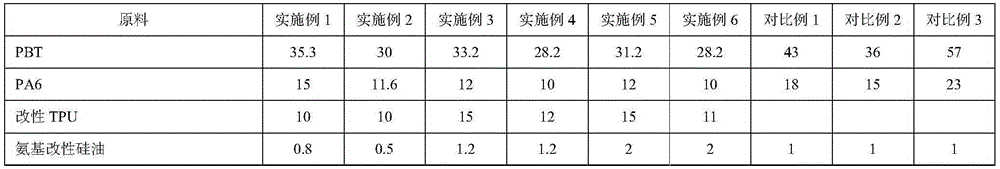

Embodiment 1

[0034] Weigh each raw material according to the following proportions: 35.3 parts by mass of PBT, 15.0 parts by mass of PA6, 10.0 parts by mass of modified TPU, 0.8 parts by mass of aminosilicone oil, and 0.8 parts by mass of aminosilane coupling agent KH550 is 0.6 parts by mass, chopped glass fiber is 20 parts by mass, decabromodiphenyl ether is 9 parts by mass, antimony trioxide is 3 parts by mass, and polyphenylene ether is 6 parts by mass. Parts, 1010 parts by mass of antioxidant is 0.1 part, and 168 parts by mass of antioxidant is 0.2 part. Add PBT, PA6, modified TPU, composite flame retardant (decabromodiphenyl ether, antimony trioxide, polyphenylene ether), antioxidant 1010 and antioxidant 168, etc. into the high-speed mixer in sequence for pre-mixing, mixing The temperature is 35°C, the rotation speed is 200 rpm, and the mixing time is 2.5 minutes to become material A; then glass fiber, amino-modified silicone oil, and aminosilane coupling agent are added to a low-spee...

Embodiment 2

[0037] Weigh each raw material according to the following proportions: 30.0 parts by mass of PBT, 11.6 parts by mass of PA6, 10.0 parts by mass of modified TPU, 0.5 parts by mass of aminosilicone oil, and 0.5 parts by mass of aminosilane coupling agent 0.6 parts by mass of KH550, 30 parts by mass of chopped glass fiber, 8 parts by mass of decabromodiphenyl ether, 3 parts by mass of antimony trioxide, and 6 parts by mass of polyphenylene ether Parts, 1010 parts by mass of antioxidant is 0.1 part, and 168 parts by mass of antioxidant is 0.2 part. Add PBT, PA6, modified TPU, composite flame retardant (decabromodiphenyl ether, antimony trioxide, polyphenylene ether), antioxidant 1010 and antioxidant 168, etc. into the high-speed mixer in sequence for pre-mixing, mixing The temperature is 30°C, the rotation speed is 250 rpm, and the mixing time is 2 minutes to become material A; then glass fiber, amino-modified silicone oil, and aminosilane coupling agent are added to a low-speed m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com