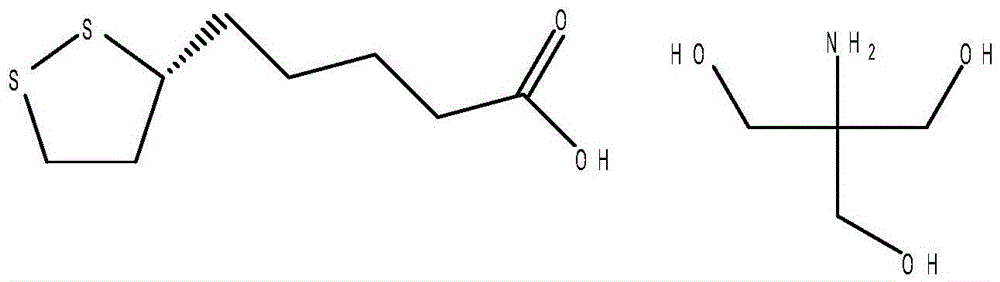

Preparation method of R-lipoic acid tromethamine salt

A technology of lipoic acid tromethamine and lipoic acid is applied in the field of preparation of R-lipoic acid tromethamine, can solve the problems of high cost, environmental pollution, multiple crystallization and the like, and meets the requirements of industrial scaled production , good green environmental protection effect, the effect of reducing process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A) Preparation of R-lipoic acid: first put (S)-6,8-dichlorooctanoic acid ethyl ester and sulfur prepared by biological enzyme into the reaction vessel equipped with a stirring device, raise the temperature to 70°C, and drop the mass The sodium sulfide aqueous solution with a percentage concentration of 8% carries out the cyclization reaction, and the cyclization reaction time is 5 hours, and the molar ratio of (S)-6,8-dichlorooctanoic acid ethyl ester, sulfur and sodium sulfide aqueous solution is 1:1.7:1 , kept at a temperature of 70°C for 2 hours, the cyclization reaction was completed, extracted with the first organic solvent, that is, toluene, and concentrated to obtain a cyclization solution, and then put the cyclization solution into a reaction vessel equipped with a stirring device and added mass percent The concentration is 4% sodium hydroxide solution for hydrolysis reaction, the molar ratio of the cyclization solution and the mass percentage concentration of 4%...

Embodiment 2

[0026]A) Preparation of R-lipoic acid: first put (S)-6,8-dichlorooctanoic acid ethyl ester and sulfur prepared by biological enzyme into a reaction vessel equipped with a stirring device, raise the temperature to 80°C, and add mass The sodium sulfide aqueous solution with a percentage concentration of 20% carries out the cyclization reaction, the cyclization reaction time is 0.5 hours, and the molar ratio of (S)-6,8-dichlorooctanoic acid ethyl ester, sulfur and sodium sulfide aqueous solution is 1:1.5:1 , kept at a temperature of 80°C for 1.5h, the cyclization reaction was completed, and the first organic solvent was extracted with ethyl acetate, concentrated to obtain a cyclization solution, and then the cyclization solution was put into a reaction vessel equipped with a stirring device and Adding the potassium hydroxide solution that the mass percentage concentration is 3% carries out hydrolysis reaction, and the mol ratio of the cyclization liquid and the mass percentage con...

Embodiment 3

[0029] A) Preparation of R-lipoic acid: First, put (S)-6,8-dichlorooctanoic acid ethyl ester and sulfur prepared by biological enzyme into the reaction vessel equipped with a stirring device, raise the temperature to 90°C, and drop the mass The sodium sulfide aqueous solution with a percentage concentration of 12% carries out the cyclization reaction, the cyclization reaction time is 3 hours, and the molar ratio of (S)-6,8-dichlorooctanoic acid ethyl ester, sulfur and sodium sulfide aqueous solution is 1:2:1.5 , kept at a temperature of 90°C for 1 hour, the cyclization reaction was completed, and the first organic solvent was used for extraction with cyclohexane, concentrated to obtain a cyclization solution, and then the cyclization solution was put into a reaction vessel equipped with a stirring device and added The sodium carbonate solution with a mass percentage concentration of 8% is hydrolyzed, the molar ratio of the cyclization liquid and the sodium carbonate solution wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| optical rotation | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com