High pressure cleaning machine and operation method of the cleaning machine

A technology of high-pressure cleaners and cleaning guns, applied to cleaning methods and appliances, cleaning methods using liquids, devices using electric/magnetic methods, etc., which can solve the problems of reducing power service life, increasing manufacturing costs, and low reliability, etc. problem, to achieve the effect of reducing operation intensity, high safety, practical and reliable program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

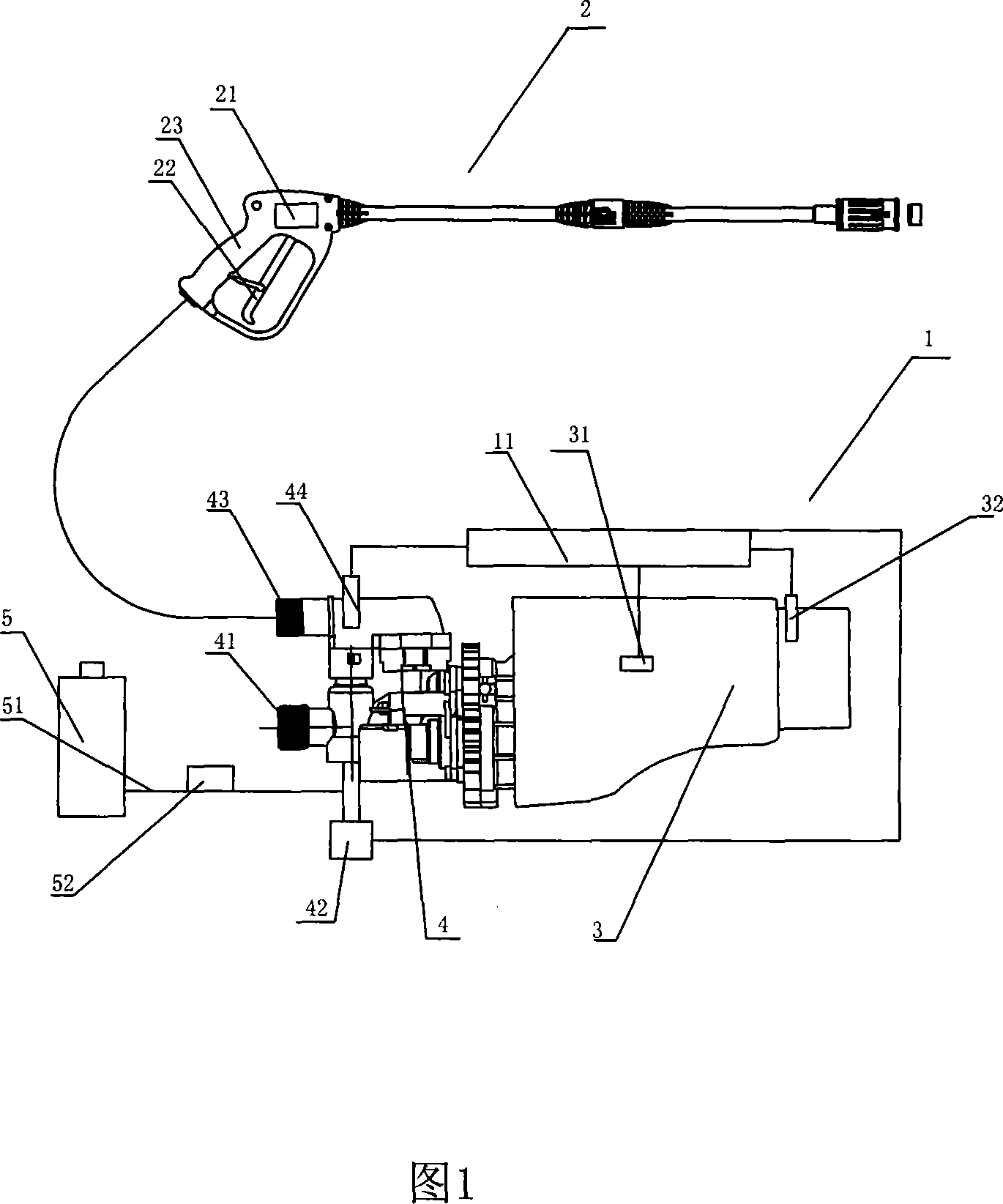

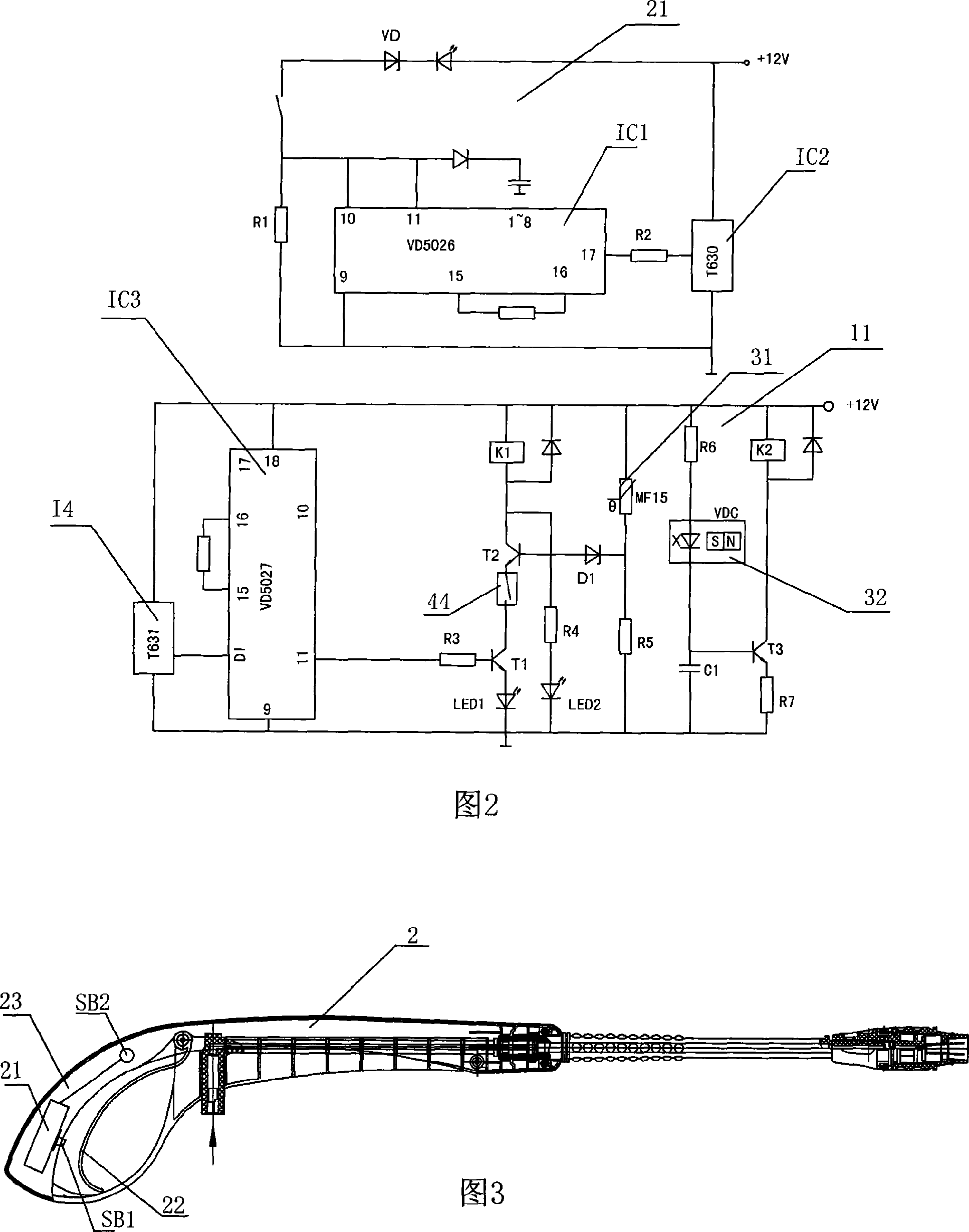

[0017] Embodiment 1: a high-pressure cleaning machine, including a host 1 and a cleaning gun 2, the host 1 includes a motor 3, a high-pressure pump 4 and a washing liquid container 5, the motor 3 is provided with a power relay switch (not shown), and the high-pressure pump 4 is provided with There is a water inlet pipe 41 connected to an external water source and an outlet pipe 42 connected to the cleaning gun 2. The washing liquid container 5 is provided with a washing liquid pipe 51 communicating with the water inlet pipe 41. The washing liquid pipe 51 is provided with a manual valve as a washing liquid switch Device 52, the cleaning gun 2 is provided with a signal transmitting device 21, the signal transmitting device 21 is provided with a first button switch SK1 corresponding to the trigger 22 of the cleaning gun 2, the host 1 is provided with a signal receiving control device 11, and the water inlet pipe 41 A water inlet solenoid valve 42 is provided, a temperature sensor ...

Embodiment 2

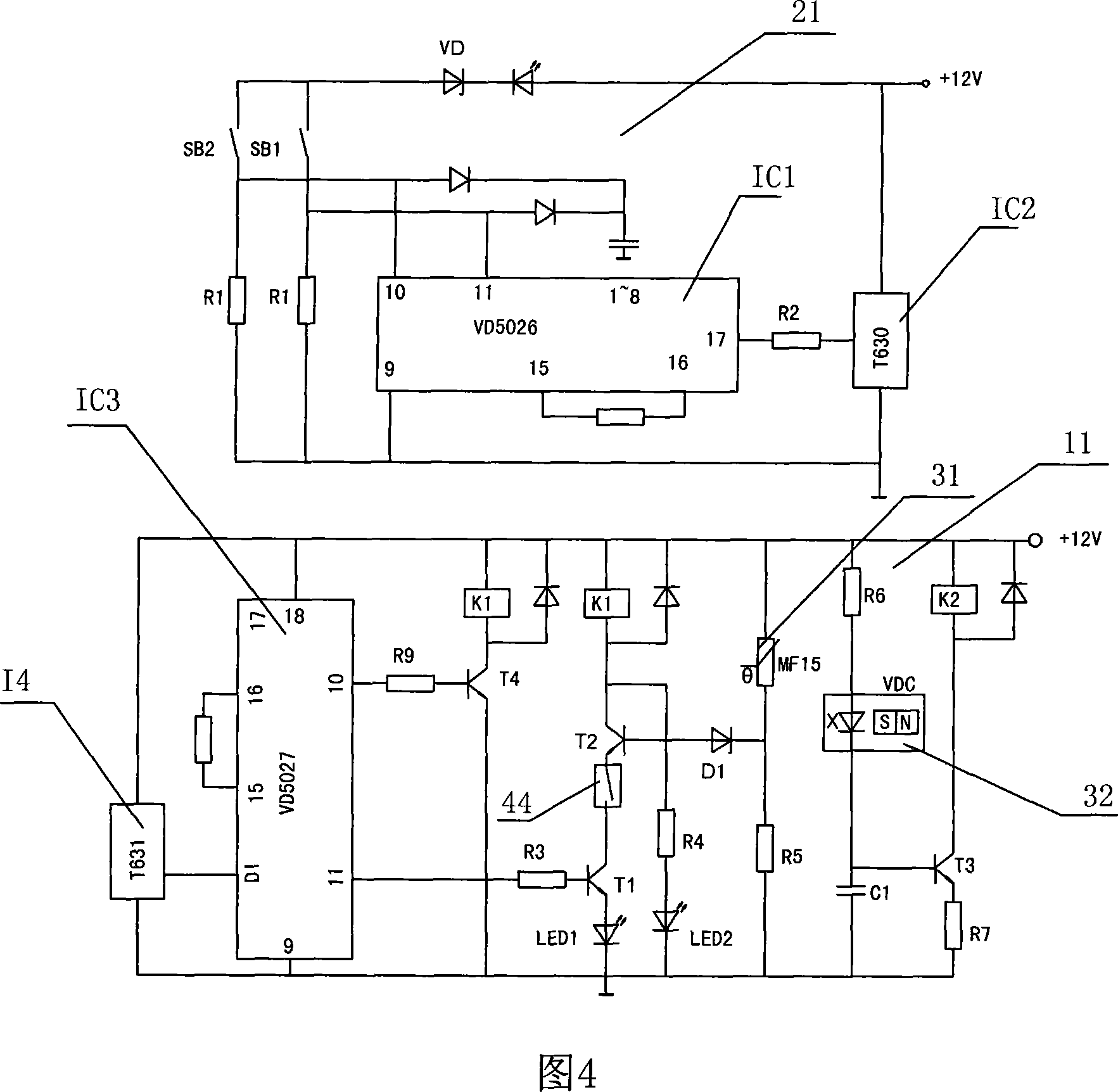

[0020]Embodiment 2: a high-pressure cleaning machine, including a host 1 and a cleaning gun 2, the host 1 includes a motor 3, a high-pressure pump 4 and a washing liquid container 5, the motor 3 is provided with a power relay switch (not shown), and the high-pressure pump 4 is provided with There is a water inlet pipe 41 connected to an external water source and an outlet pipe 42 connected to the cleaning gun 2. The washing liquid container 5 is provided with a washing liquid pipe 51 communicated with the water inlet pipe 41. The washing liquid pipe 51 is provided with a washing liquid electromagnetic valve as a cleaning solution. The liquid switch device 52, the cleaning gun 2 is provided with a signal transmitting device 21, the signal transmitting device 21 is provided with a first button switch SK1 corresponding to the trigger 22 of the cleaning gun 2, and the handle 23 of the cleaning gun 2 is provided with a second button switch SK2, the host 1 is provided with a signal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com