Pulse wind tunnel operation control system and pulse wind tunnel operation control method

An operation control and wind tunnel technology, applied in measurement devices, instruments, aerodynamic tests, etc., can solve problems such as unfavorable maintenance, easy failure, and long air supply lines, so as to improve the accuracy of data acquisition and control, and ensure the safety of personnel. The effect of operating safety and reducing the intensity of personnel operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

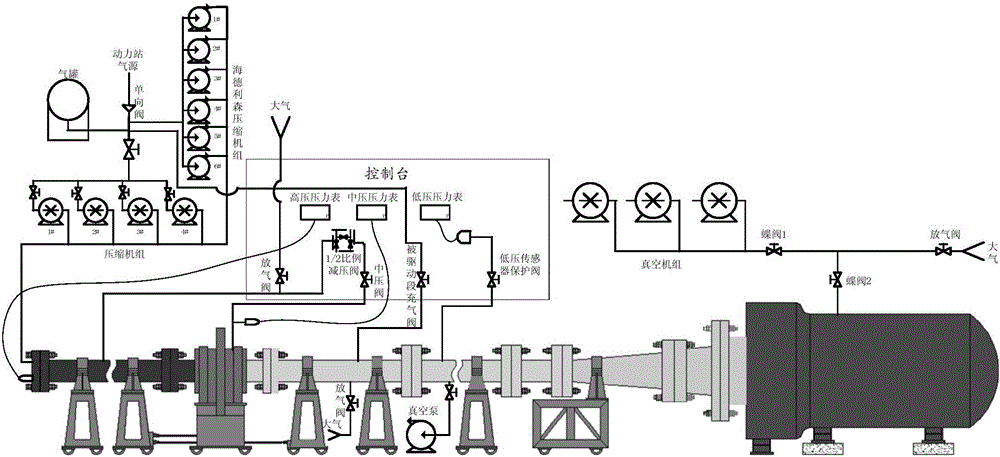

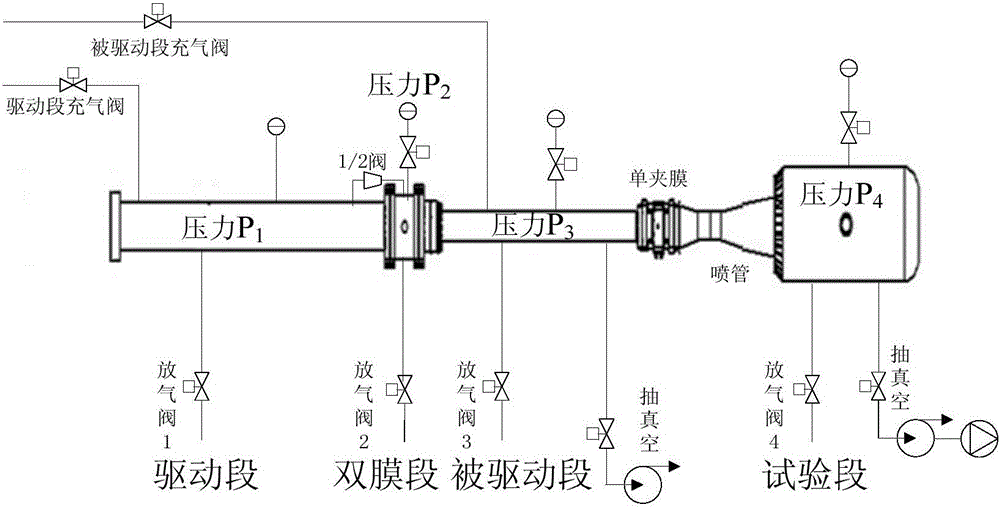

[0040] The pulse wind tunnel operation control system of the present invention includes a PLC module, a driving section inflation valve, a driving section deflation valve, a driving section pressure sensor, a 1 / 2 valve, a double-membrane section deflation valve, a double-membrane section pressure sensor, and a driven section Inflatable valve, deflation valve of the driven section, pressure measurement module of the driven section, vacuum valve of the driven section, deflation valve of the test section, vacuum valve of the test section, pressure sensor of the test section, and vacuum unit. Realize the following functions:

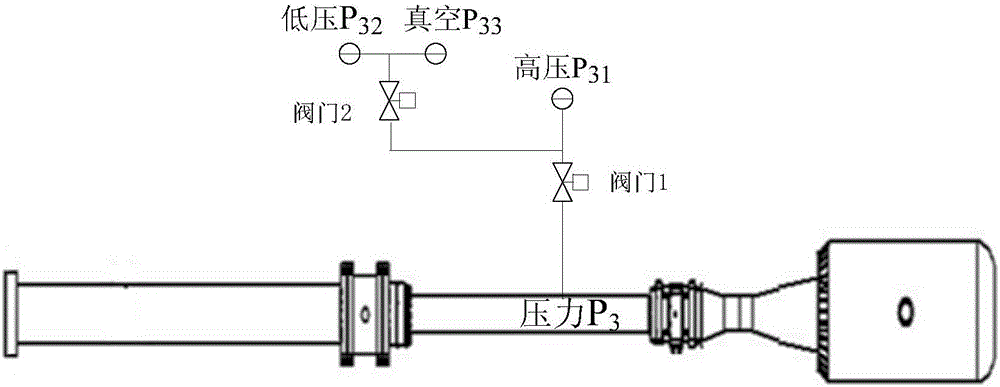

[0041] 1. Segmented pressure measurement and data recording

[0042] The driven section is connected with the high-pressure pressure measurement pipeline, and the measurement gas circuit is controlled by valve 1. The high-pressure pressure measurement pipeline behind valve 1 is connected with the low-pressure pressure measurement pipeline, and the low-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com