Method for lowering gravity center of crane arm support

A crane and boom technology, applied in the field of cranes, can solve the problems of cumbersome operation, increase the operating cost of crawler cranes, and reduce the work efficiency of crawler cranes, and achieve the effects of simple operation, lowering the center of gravity, and preventing tipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a first preferred embodiment of the present invention, the method for lowering the center of gravity of the jib of a crane comprises the following steps:

[0023] Step 1: Connect the crane pull plate connected to the top of the jib to a jib section of the jib;

[0024] Step 2: Fold the jib at the jib section;

[0025] Step 3: Connect the folded booms at both ends through the bracket;

[0026] Step 4: Finally, vertically connect the folded jib to the crane through the pull rope.

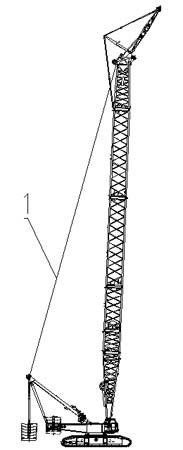

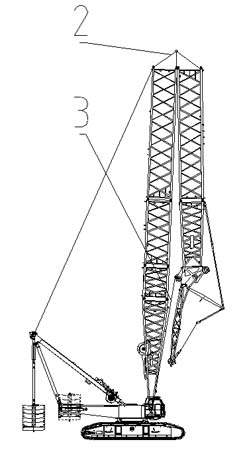

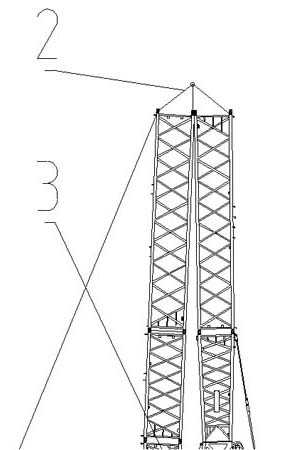

[0027] After being folded, the state of the crane jib is as follows figure 2 shown. The pull plate 1 originally connected to the top of the jib is connected to a certain jib section of the jib, and the bracket 2 is used to connect the folded jib, so that the unfolded and folded two parts are firmly connected together. In order to ensure the stability of the folded jib, the folded jib is connected to the crane with a stay rope 3 to prevent it from swinging back and forth too much, so as ...

Embodiment 2

[0029] In a second preferred embodiment of the present invention, the method for lowering the center of gravity of a jib of a crane includes the following steps:

[0030] Step 1: Connect the first stay rope of the crane connected to the top of the jib to a jib section of the jib;

[0031] Step 2: Fold the jib at the jib section;

[0032] Step 3: Connect the folded booms at both ends through the bracket;

[0033] Step 4: Finally, vertically connect the folded jib to the crane through the second stay rope.

[0034] In this embodiment, the method for lowering the center of gravity of the jib of the crane is basically the same as the method in the first preferred embodiment, except that under the appropriate lifting requirements, a pull rope can be used to connect a certain jib joint to maintain the balance of the crane. the goal of.

Embodiment 3

[0036] In a third preferred embodiment of the present invention, the method for lowering the center of gravity of the jib of a crane includes the following steps:

[0037] Step 1: Connect the crane pull plate connected to the top of the jib to the middle arm of the jib;

[0038] Step 2: Fold the jib at the middle arm;

[0039] Step 3: Connect the folded booms at both ends through the bracket;

[0040] Step 4: Finally, vertically connect the folded jib to the crane through the pull rope.

[0041] In this embodiment, the method for lowering the center of gravity of the jib of the crane is basically the same as in the first preferred embodiment and the second preferred embodiment, except that the stay rope in step 1 is specifically limited to be connected to the middle arm of the jib. In this way, the jib is folded along the center, and the folded two parts of the jib are symmetrical, so that the center of gravity of the folded crane is minimized, ensuring the overall stability...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com